Plastic Extrusion Products

Yuyao Xianghao Mold Technology Company Limited- Molding Material:Metal Mould

- Material:Steel

Base Info

- Transport Package:Steel Box

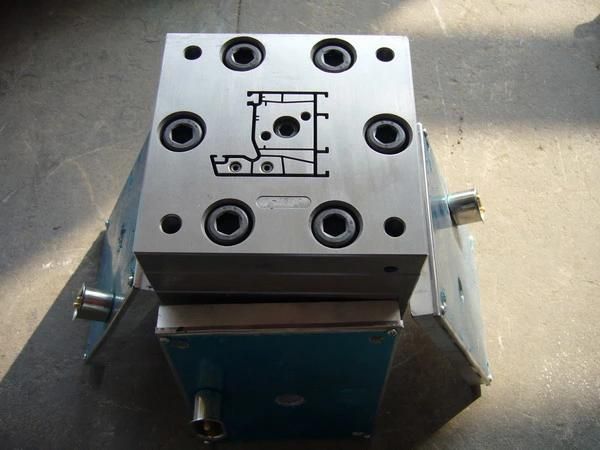

- Plastic Profile Extrusion Mold for Windo:Plastic Profile Extrusion Mold

- Metal Mould:Forging Die

- Non Metal Mould:Plastic Mould

- Pressure of Nose:High Pressure

- Outlet:Group Control Multi-mode

- Nose Application:Profile Molding

- Extrusion Mould:Hollow Mould

- Extrusion:Extrusion

- Model NO.:plastic extrusion products

- Specification:CE ROHS

- Trademark:darrow

- Origin:China

- HS Code:8480410010

- Production Capacity:100 Sets Mold Per Month

Description

Basic Info.

Model NO. plastic extrusion products Extrusion Extrusion Extrusion Mould Hollow Mould Nose Application Profile Molding Outlet Group Control Multi-mode Pressure of Nose High Pressure Non Metal Mould Plastic Mould Metal Mould Forging Die Plastic Profile Extrusion Mold for Windo Plastic Profile Extrusion Mold Transport Package Steel Box Specification CE ROHS Trademark darrow Origin China HS Code 8480410010 Production Capacity 100 Sets Mold Per MonthProduct Description

We primarily manufacture customized die's for Plastic, rubber and aluninium extrusion profilesWe however ,do also have facilities for the production/manufacture of the plastic,rubber and aluminium finished product.as per the customers request.

What we would need on an enquiry to quote and to procced in the most efficient manner if possible, would be to get a sample, drawings and weight of the part or parts in question.

This will greatly assist us in getting accurate pricing.

Depending on the project, we will then proceed with the design work to create 3D drawings and if requested will provide prototypes for review, at a minimal cost.

The MOQ for the production of extruded profiles is 100 meters

Extrusion materials for production PP PA ABS PVC PC PMMA Various grades of rubber and aluminium alloy's

Extrusion die lead times are +- 14 days

We look forward to your enquiry and will be of assistance at any given time.

more information please visit our website: http://darrow.en.made-in-china.com

Our minimum order quantity for products is 100 pieces

All our products carry a 3 year warranty.

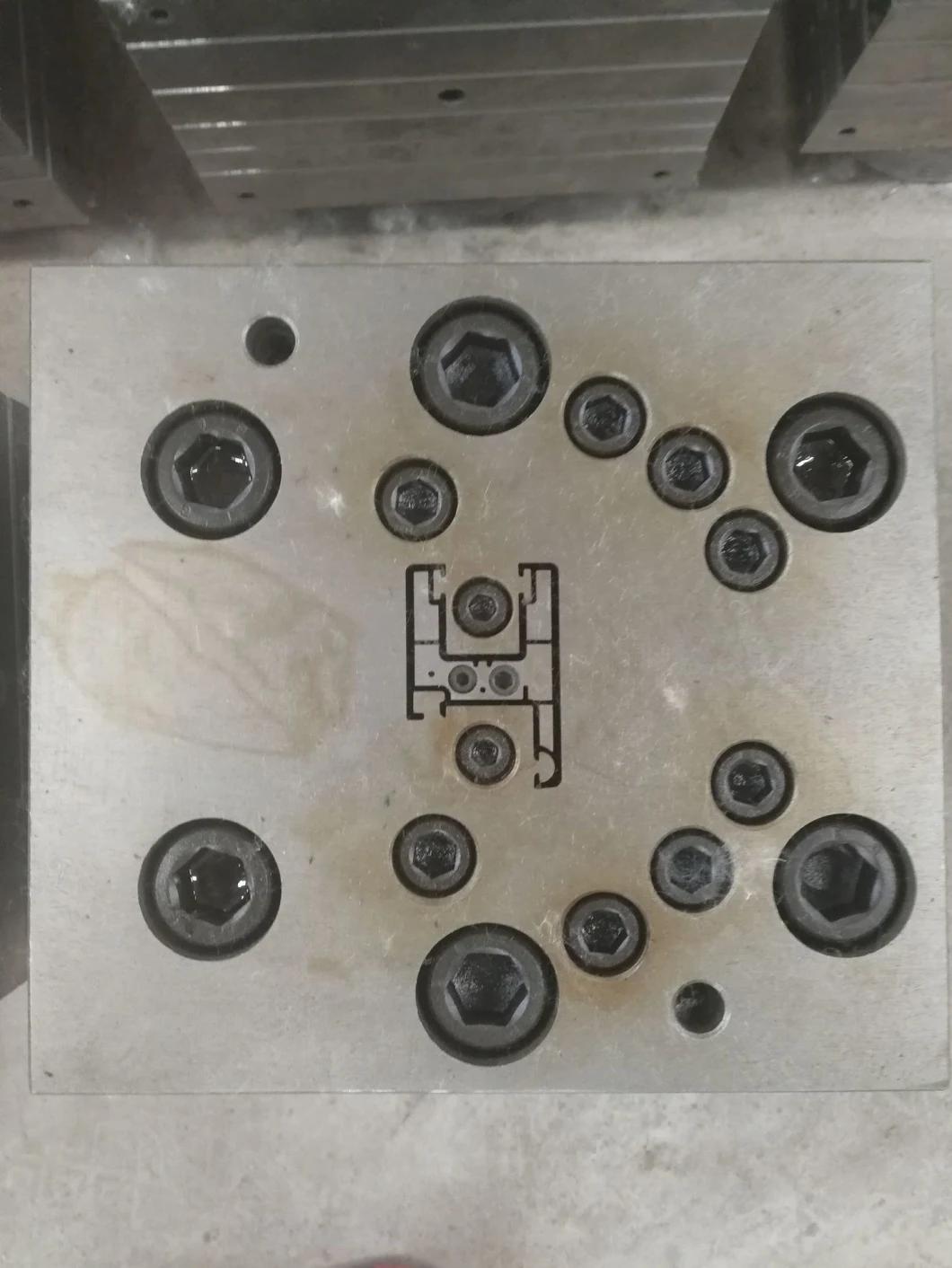

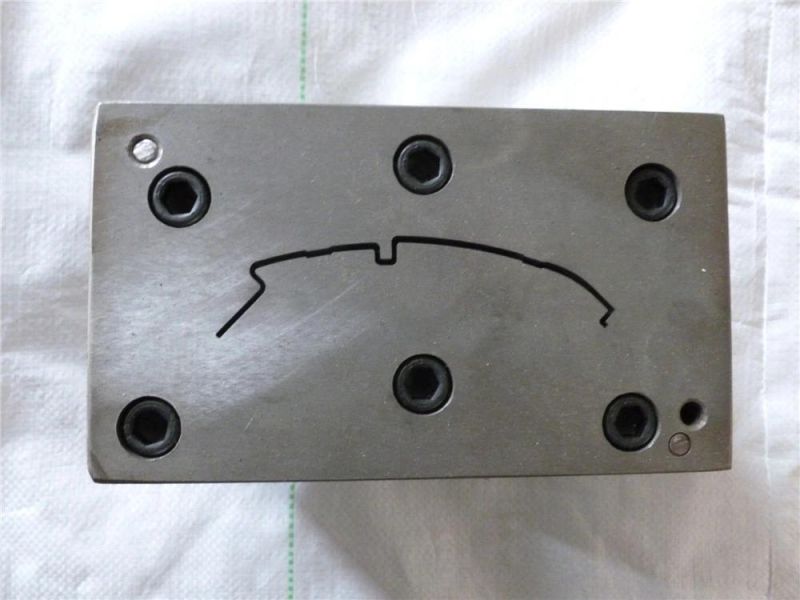

Extrusion Mold for Windows Panel

Specifications

Plastic Extrusion Mold For Baseboard

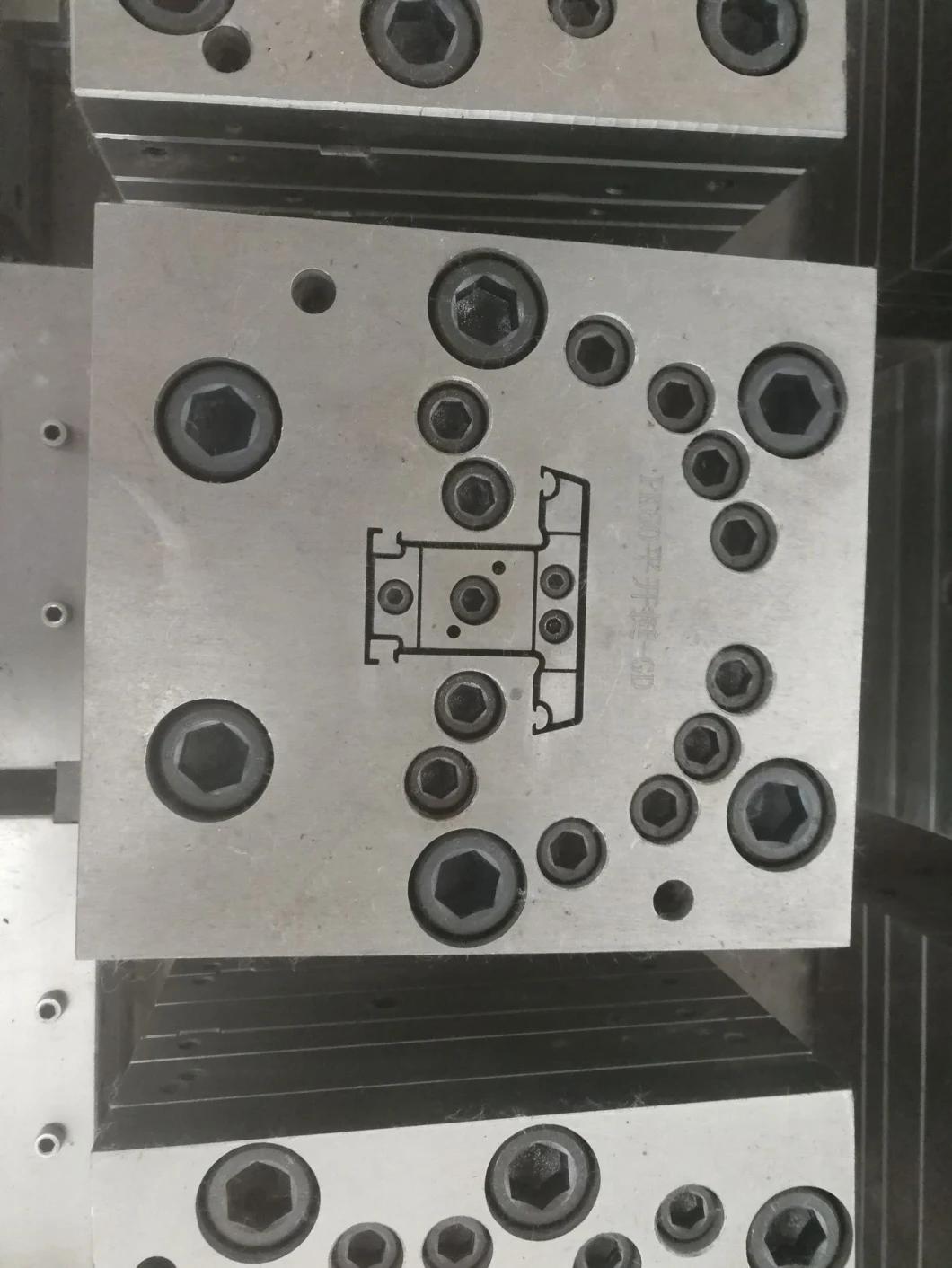

1. High Quality 3Cr13 Mould Materail

2. OEM Service Accepted

3. Over 10 Years Experience

Plastic Extrusion Mold For Decorative Baseboard

Detailed Product Description:

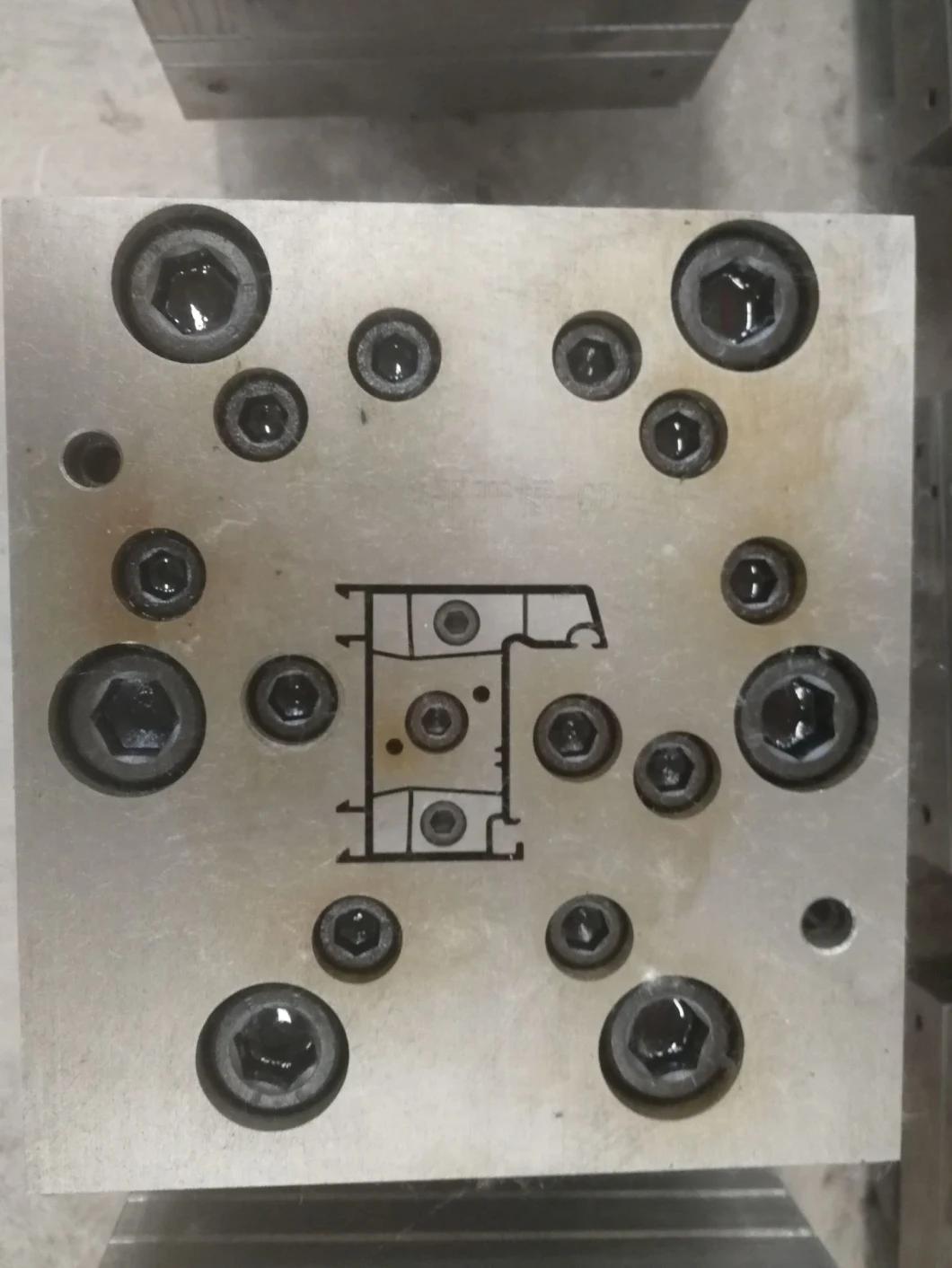

1. Advanced mirror polished surface treatment technology.

2. High quality 3Cr17 stainless steel material for pvc extrusion profile mould.

3. Configuration: One die head + four heating plates+three-segment calibrator +two-meter stainless water tank or as you require.

It is our duty to provide you with good quality products and our best service!

Our Advantages Of PVC Extrusion Mold:

1. We are the one of biggest PVC profile extrusion mould designers and manufacturers in Huangshi.

2. Our pvc profile window and door extrusion moulds account for the majority China market with all specifications.

3. Rich experience: Over 20- years of experience in the pvc profile extrusion mould industry with trustworthy skills, offering comprehensive services.

4. High-quality, high speed, high precision plastic extrusion moulds and reasonable prices.

5. Different PVC, PE, PPR, ABS, Pc and other plastic pipe mould, wpc wood plastic composite mould.

6. We can provide a whole set to technical support including extruder election, formulas process and extrusion mould.

Name | Plastic Extrusion Mold For Decorative Baseboard |

Size | Various types |

Mould material | 3Cr17, 3Cr17MoNiV,or as per your request |

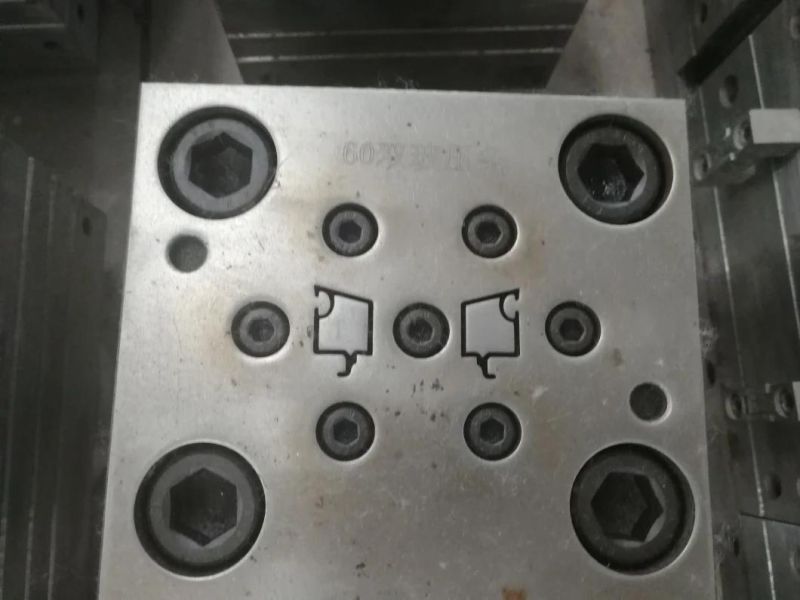

Mould cavity | 1 or multi-cavity |

Mould composition | Die head, aluminum heating bands, calibrators and water tank |

Feature | Selectable co-extrusion of different raw materials: PVC, PP, PE, ABS Selectable technology: low-foaming, high-foaming & substance co-extrusion Stable discharging, high efficiency, superior quality |

Test | Mould will be tested to get the satisfied sample before delivery |

Service | Provide complete set of production process and technology transfer service |

Lead time | 35-40 days |

Package | Wooden case for exporting, each mould will be cleaned before packaging. |