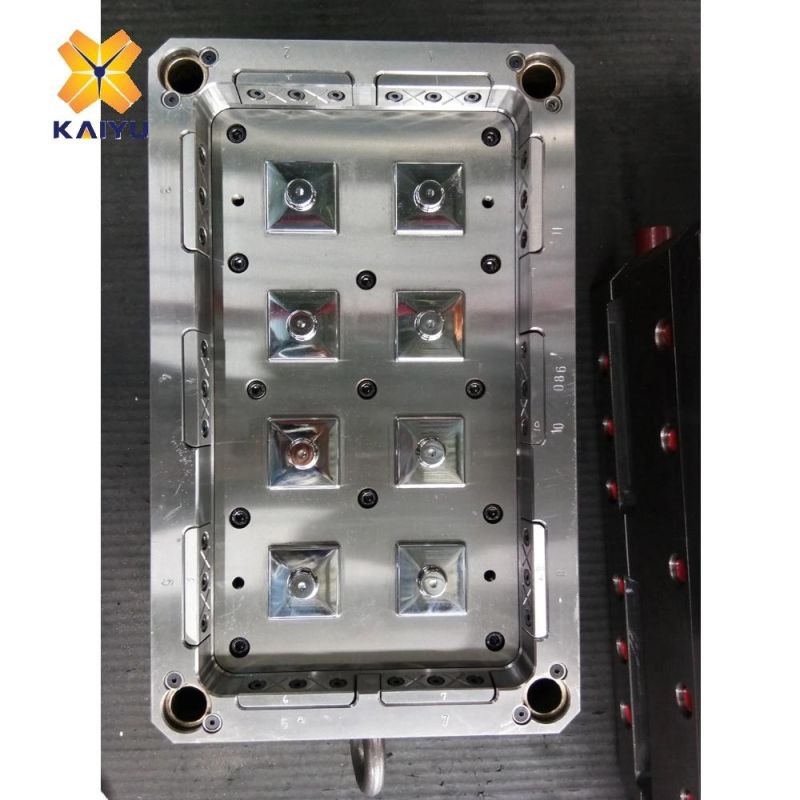

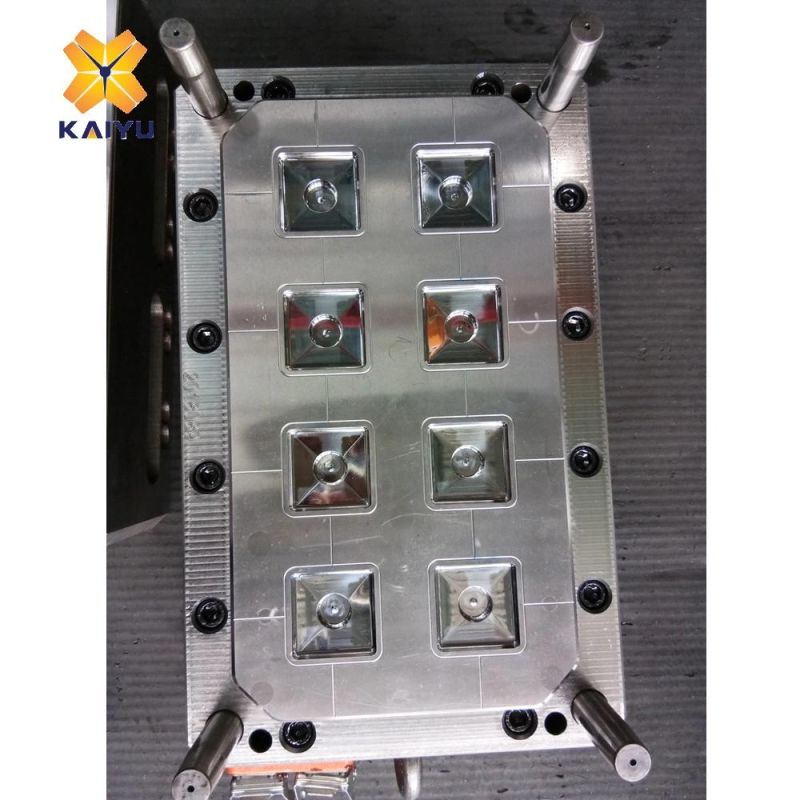

Plastic Product Part Injection Mould

Taizhou Kaiyu Mould Co., Ltd.- Process Combination Type:Compound Die

- Plastic Material:Acrylic

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Commodity, Home Use

Base Info

- Trademark:KY Mould

- Transport Package:Wooden Case

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:standard

- Origin:Taizhou

- HS Code:8480719090

- Production Capacity:700

Description

Basic Info.

Model NO. standard Runner Hot Runner Design Software UG Installation Fixed Certification CE, ISO Standard HASCO Customized Customized Transport Package Wooden Case Trademark KY Mould Origin Taizhou HS Code 8480719090 Production Capacity 700Product Description

TAIZHOU HUANGYAN KAIYU Mould General Sepcification :WE ACCEPT OEM&ODM ORDERS.

We are a plastic injection mould maker for thin wall packaging mould, daily used plastic product mould according to different customer's requirements.

The quotation will be offered based on the samples,or part drawing,or the sample photos.

Taizhou Huangyan KAIYU Mould co.,ltd will satisfies you both in mould

quality and mould price.

We are looking forward to a solid cooperation with you.

Following is the main informations for your reference.

· Qualified steel with high hardness

· Nice polish with high brightness

· Nice machining with high precision

· Customized designs are accepted

· One-year after-sale service for free

1. Short cycle time and high efficiency in production.

2. Each cavity and core have independent cooling system, shortening production cycle time.

3. Rational mould design to extend mold life .

4. Mirror hand polishing to create added-value.

4. Precision Machining to ensure high production efficiency & fine parting line effect.

5. Skilled Language in communication and experienced in international standard.

F A Q

- Are you trading company or factory?

2.How long is the lead-time for mold?

It all depends on the mold's size and complexity. Normally, the lead time is 55-65days.

If the molds are very simple and not big size, we can work out within 50 days.

.

3.What's your after sales

For any products quality problems, we will replace at our expense. However, we will need to establish a clear quality inspection criteria at the beginning stage of the project.

We also have an CRM system to keep work history with all customers.

4..What's design software do you use for making drawing?

UG, Pro-E, Master cam, Solid works, 3D max, AutoCAD, CAM.

Drawing format( 2D file- dwg, dxf/pdf, jpg), 3 D model format( igs, x_t, prt)

General procesure

.Customer sends us sample or drawings

↓

2.Discuss the options for the project,such as raw material,delivery time, ect.

↓

3. Details confirmed,and send the quote sheet to customer.

↓

4. Purchase raw material and make some samples for customer confirm before mass production.

↓

5.Start production aster the samples approved by customer,and packaging.

↓

6. Shipping and Delivery after the parts completed,we will arrange the shipment by sea or by air.

↓

7. After sales services.We are always available,include the weekend,and holidays.

For more mould or product information. welcome your inquiry !

Mobile : 0086 152 5858 9130