Customized OEM Stamping Mould Parts/ HSS Brass Punch Pins Molding Components

Dongguan Xinrui Precision Mold Co., Ltd.- Process Combination:Single-Process Mould

- Technics:Cutting Die

- Processing Method:Punching and Shearing Mould

- Material:Hard Alloy and Steel Bonded Carbide

- Application:Electronic, Hardware, Car, Commodity

- Manufacturing Technology:Automation Technology

Base Info

- Payment Term:30,50% Prepayment, 70,50% Balance Before Shipping

- Payment Method:T,T, L,C, D,P, Wester Union, Credit Card

- Trade Term:Fob,EXW,Fac,CIF,CFR

- Drawing Format:2D,3D, Pdf

- Surface Treatment:Anodizing, Powder Coating, Polishing

- Parts Detection Method:Measurement of Three Axis NC

- Milling Speed:High Speed

- Mold Cavity Technology:The Traditional Forming Electrode Machining

- Driving Motor Type:Permanent Magnet

- Model NO.:S31

- Shipping Method:by Sea, by International Express

- Transport Package:Carton+Wooden Box

- Specification:Customized

- Origin:China

- HS Code:7326191000

- Production Capacity:500000PCS,Year

Description

Basic Info.

Model NO. S31 Driving Motor Type Permanent Magnet Mold Cavity Technology The Traditional Forming Electrode Machining Milling Speed High Speed Parts Detection Method Measurement of Three Axis NC Surface Treatment Anodizing, Powder Coating, Polishing Drawing Format 2D/3D, Pdf Trade Term Fob/EXW/Fac/CIF/CFR Payment Method T/T, L/C, D/P, Wester Union, Credit Card Payment Term 30/50% Prepayment, 70/50% Balance Before Shipping Shipping Method by Sea, by International Express Transport Package Carton+Wooden Box Specification Customized Origin China HS Code 7326191000 Production Capacity 500000PCS/YearProduct Description

| Product Name | precision injection mold components mold parts. |

| Material | SKD61,SKD11,NK80,S316,SUS304,or as your request |

| Color | nickel white,sliver,black,or as your request |

| Tolerance Standard | ISO2768-F,M, and according to the drawings or samples |

| Min Tolerance | 0.002mm |

| Surface treatment | Harden,plating,anodizing,nitriding,powder coating,etc. |

| Standard | non-stanard,OEM service. |

| processing eqquipment | automation cnc machine,wire EDM,spark machine,stamping machine,laser engrave machine,thread rolling machine,plastic injeciton machine,Air compress machine,etc.. |

| measure instrument | microscope,2D/3D diamesional instrument,profile projector,magnifying glass,height gauge,thickness meters,vernier caliper,Altimeter,spectrum analysers,etc |

| Design software | UG,PRO-E,CAD, |

| Used | plastic injection mold,hardware mold,blow mould,silicon mold,etc, |

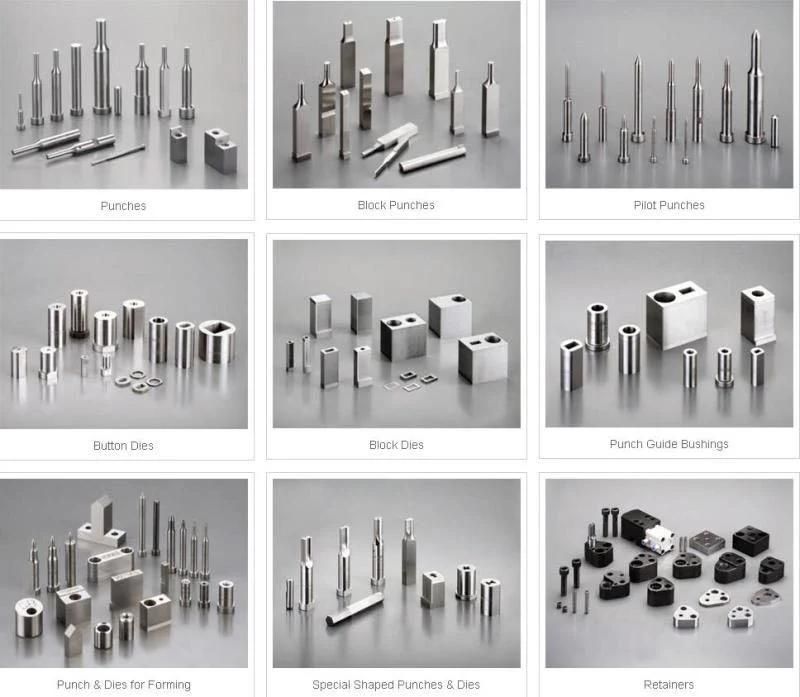

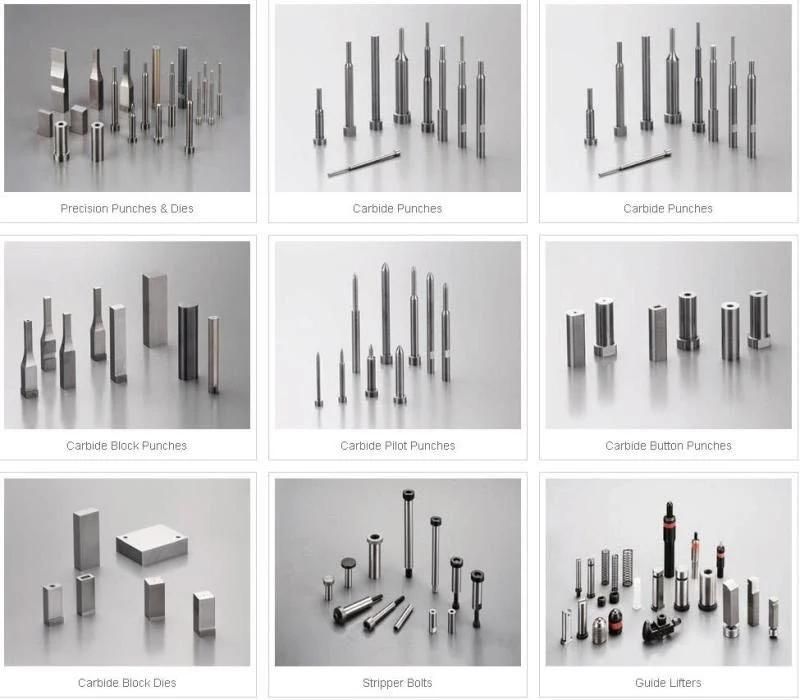

Product Show:

Factory Show:

Company Introduce:

XingRui Precision Mould Co.,Ltd is an processing enterprise to produce hardware mould and plastic mould precision fittings professionally.we can meet users diversified and special production requirements comprehensively by tens of years of experince by relying on shound management,excellent technology and processes,we also can provide complete tungsten steel solutions for users especially by breakthrough in tungsten steel parts processing field.

Our company has the most advanced processing process in tungsten steel punch,bushing,and special forming punch,stator,special rotor punch and die,tungsten steel mechanical parts,ceramic mould parts and other fields in the same industry for a long time,we have more unparalleled advantages when guaranteeing high quality and synchronous delivery.

Over the years we cntinue to invest in precision plastic plastic mould parts and automation equipment,introduce advanced CNC equipment and cultivate various kinds of excellent talents to completely support the continuous of company's development,now processing products of our company cover hardware mould,plastic mould,electrical and electronics,automotive,stationery,medical equipment and mechanical parts and other industries,company achievements also increase steadily,

Our company always insists in "the best quality,the fastest delivery,the most reasonable price and the most attentive service"to thank new and old users for their support and help.

FAQ

Q: What do I need for offering a quote ?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.) ,quantity, application or samples. Then we will quote the best price within 24hrs.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers' requirement by adjusting our workshop schedule.

Contact us:

Julie Yang

TEL:+0086 769 82226228

Mobile:+86 137 11807865

ADD: No.58 Sukeng Village Great Hall, Changping Town,Dongguan city,Guangdong Province, China