Supply 3D Printing and Mold for Plastic Case for Cometic Product

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Furniture, Electronic, Hardware, Household Appliances, Commodity, Home Use

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Single Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Lead Time:7-14 Days for Samples, 25-40 Days for Mould

- Mold Base:Hasco, Dme, Lkm, Jls Standard

- Main Service:3D Design, Prototypes, Mold Design, Mold Making, etc

- Steel Hardness:20-60HRC

- Surface Treatment:Polishing,Smooth, Texture,Frosted, Printing, etc

- Mold Life:300K to 500K Shots

- Name:Plastics Injection Mold

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Hot Runner

- Model NO.:HW-1054

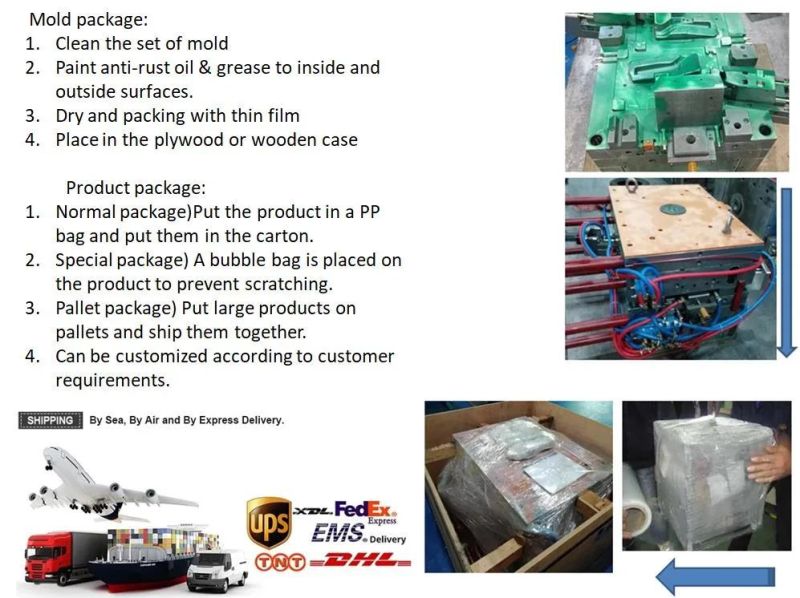

- Packing:Standard Export Wooden Box

- Transport Package:Wooden Cases,Air,Sea

- Specification:Custom

- Trademark:HOWE or Custom

- Origin:China

- HS Code:8522901000

- Production Capacity:40sets,Month

Description

Howe precision mold Co. is a full service supplier of injection molds for the plastics industry. We have been manufacturing injection molds since 2010. We constantly strive to improve through the utilization of new technologies, advanced equipment, and our delication to quality. All of our molds are designed, engineered and constructed to each customers' specific product application and company standards.

Howe's value-added injection molding services include, but not limited to,

•Material selection and design advice

•Prototyping and production

•Plastic parts and component

•Secondary processes

•Ultrasonic welding

•Silk printing and Pad Printing

•Assemblies and Package

1.Custom Plastic Injection Parts

2.Multi-cavity plastic parts

3.High Precision Molds

4.Insert & over molding

5.Double Shot Mold(2K mold)

6.Unscrewing Molding

7.Gas-assisted Molding

8.Die Casting Molding

9.Prototype plastic parts and Low cycle plastic parts molding

10Gas Assist molding

11.Elastomeric molding

12.IML & IMD part production

13.Thin wall plastic molding

14.High temperature molding