Direct Factory OEM ODM 300000 to 1000000 Shots Plastic Injection Mould

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Furniture, Electronic, Hardware, Household Appliances, Commodity, Home Use

- Process Combination Type:Single-Process Mode

- Plastic Material:PE

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Molding Material:ABS, PC, PP, PE, PA, PS,+GF, POM, PMMA,Ect.

- Mould Material:M2, Skh-9, Skh-51, M35, M42, Asp23

- Gate Type:Side Gate,Sub Gate,Pin Point Gate,Edge Gate etc

- Mold Life:300, 000 to 1,000,000 Times

- Mold Standard Components:Hasco, Misumi, Meusburger, Dme, etc

- Product Name:Plastic Injection Molds

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Cold Runner

- Model NO.:HW-1037

- Payment We Support:T,T, Paypal

- Transport Package:Wooden Cases,Air,Sea

- Specification:Custom

- Trademark:HOWE or Custom

- Origin:China

- HS Code:8522901000

- Production Capacity:40sets,Month

Description

Mould Trade Process

1. 3d Design/Samples for quotation: According to 3D drawing or samples for quotation.

2. Negotiations: Including the price of moulds, moulds sizes, material for cores & cavities, the weight of the product, part cost, payment, moulds lifetime, delivery, etc.

3. Purchasing Order: After the customer confirming the mould design and quotation.

4. Making mold: Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production.

5. Production schedule: Every week we will feedback to the customer mold progress(picture).

6. sample shoot: We provide the moulds test samples for confirmation(about 10-15 pieces), then, get your signature sample, mass production.

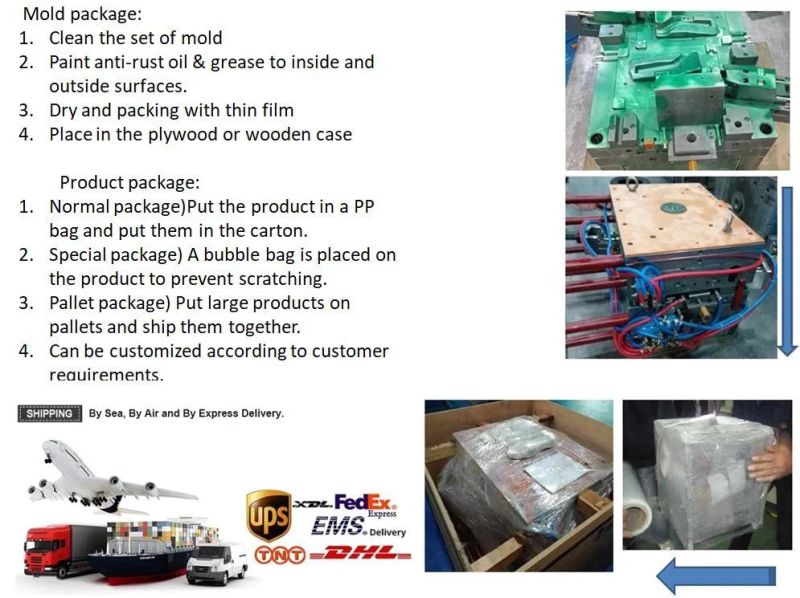

7. Package: Wooden case for moulds, cartons for parts, or as your requirements.

8. Delivery: deliver goods by air or by sea.

Work Shop

1. Manufacturing and exporting experience for nearly 11 years.

2. Products are supplied to over 20 countries.

3. One-stop service for aluminium profiles, plastic parts, rubber parts and moulds. Save time and save money for you.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. 24 hours (two shifts) / 6 days for production.

8. Professional design team, mold maker engineer. OEM/ODM service.

9. Professional QC and R&D teams to assure high quality.

10. Professional sales team. Good English capabilities and communication skills.

11. No MOQ.

12. Prompt delivery. For prototype :3-7 days. Production orders can be arranged specially to meet customer's urgent demands.

13. Geographical advantages: within 30 minutes to airport or sea port, near to Hongkong.

You can contact customer service to know more about us, Looking forward to having a good start for our reliable cooperation!

Packaging & Shipping