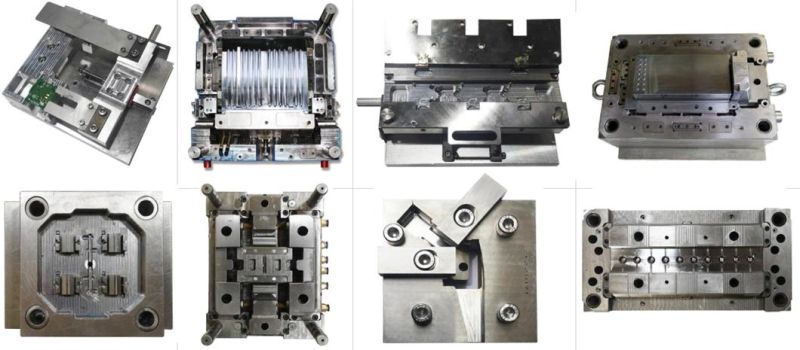

High Quality Components Plastic Injection Mould Plastic Parts for Car

Qingdao Chuangyu Precision Machinery Co., Ltd.- Surface Finish Process:Polishing

- Mould Cavity:Multi Cavity

Base Info

- Condition:New

- Runner:Hot Runner

- Design Software:Pro-E

- Installation:Mobile

- Certification:CE, ISO, CE, ISO9001, CE, ISO9001, CE, ISO9001, CE, ISO9001, CE, ISO9001, CE, ISO9001

- Standard:HASCO, GB, JIS, GB, JIS, GB, JIS, GB, JIS, GB, JIS, GB, JIS

- Customized:Customized, Customized, Customized, Customized, Customized, Customized, Customized

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Casting Machinery, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Casting Machinery, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Casting Machinery, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Casting Machinery, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Casting Machinery, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Casting Machinery

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Model NO.:CMP01

- Material:Metal

- Transport Package:Cartons, Wooden Pallet or Customized

- Specification:up to design

- Trademark:Chuangyu

- Origin:China

- HS Code:8480419000

- Production Capacity:5000pieces,Month

Description

Certification:

Shipment:

We usually delivery the moulds and machinery parts by sea/DHL/FEDEX/TNT, according to the customers.

FAQ:

1. Q: what is the processing for the quote ?

A: We can quote from your 3d formats like IGS,STP,PARASOLID etc and 2D drawings as well; quote the price to clients after got the 2d or 3d drawings within 2 hours;

2. Q: How is the next ?

A: We will send the cost to you and get your confirmations for the quote;

3. Q: what is the software will you use for the proceeding ?

A: We make the 3D programm with Pro-Engineer, UGS, SOLIDWORKS, MASTERCAM etc ;

4. Q: what is the type of machines for manufacturing ?

A: Manufactured from CNC Machining, Laser cutting , stamping ,injection as well as the parts files different ;

5. Q: Do you do the surface treatments please ?

A: Yes, sure. we do the surface treatments, for instance: chromated, powder coating, Anodizing, laser etching as well as painting ;

6. Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping;

Why choose us?

1. We have more than 10 years experience for production

2. We have an extensive expertise in CNC machining, offer "One-stop Service".

3. Now we have more than 35 sets of various processing equipment. There are 15 people in professional technology, R&D team.

4. All of our operations are strictly compliant with ISO 9001: 2015 guidelines.

5. We have office in Germany as to offer better service to our clients.

Contact Info:

If you have any doubts, please do not hesitate to contact me.