- Specification:550*450mm

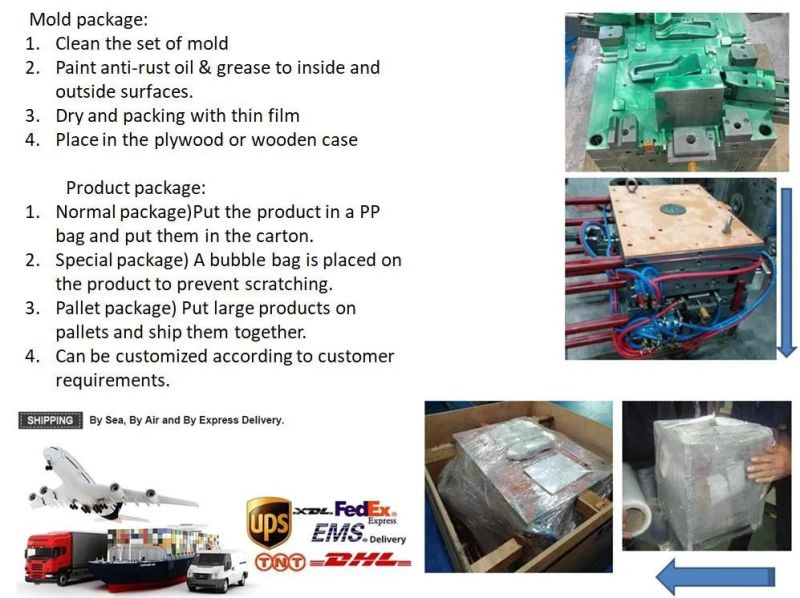

- Transport Package:Wooden Cases,Air,Sea

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, CE, ISO, FDA

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:HW-07539

- Trademark:Customized

- Origin:China

- HS Code:8480719090

- Production Capacity:30sets,Month

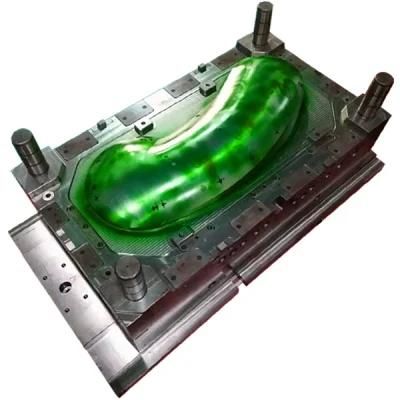

| Mold information | content |

| Product Material | ABS,PP,PC,PA,PMMA,PS,POM and etc. |

| Moldbase | FUTABA,LKM,HASCO,DME you can choose |

| Cavity material | 45#,50#,P20,H13, 718 2738, NAK80, S136, SKD61 etc |

| Runner | Cold/Hot runner |

| Cavity | Multi or single cavity |

| Standart parts | Hasco |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Treatment | Heat treatment and Nitriding,polish ect. |

| HRC | H45~52 |

| Product weight | 50~5000 K |

| Machine type | 250Ton |

| The standard of appearance of the products for stripe | MT(Mold Tech),YS,HN series |

| The way of Color contrast | RAL K7,PANTONE |

| Plastic Mold (Moulds) production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2 .Negotiations | Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, part cost, payment, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold(moulds) | Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer a mold progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15 piece), then, get your signature sample ,mass production. |

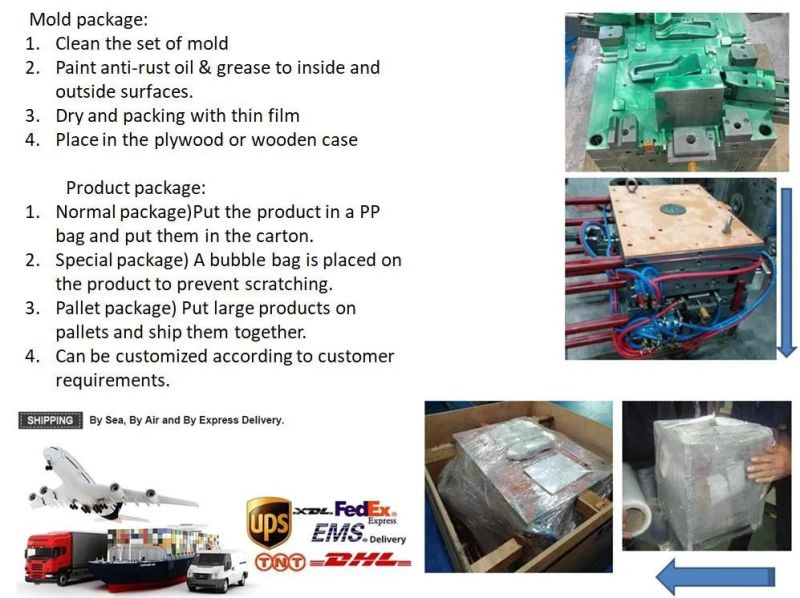

| 7. Package | Wooden case for moulds, cartons for parts ,or as your requiretment. |

| 8. Delivery | deliver goods by air or by sea. |

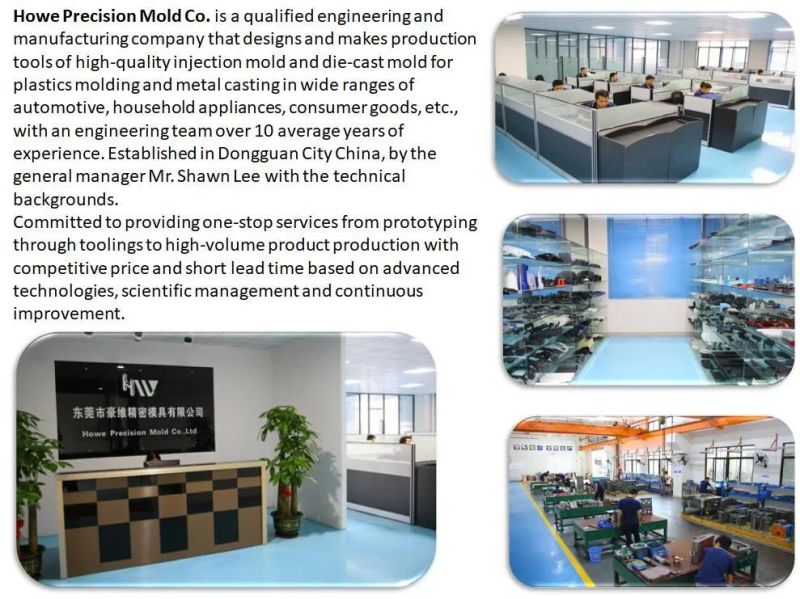

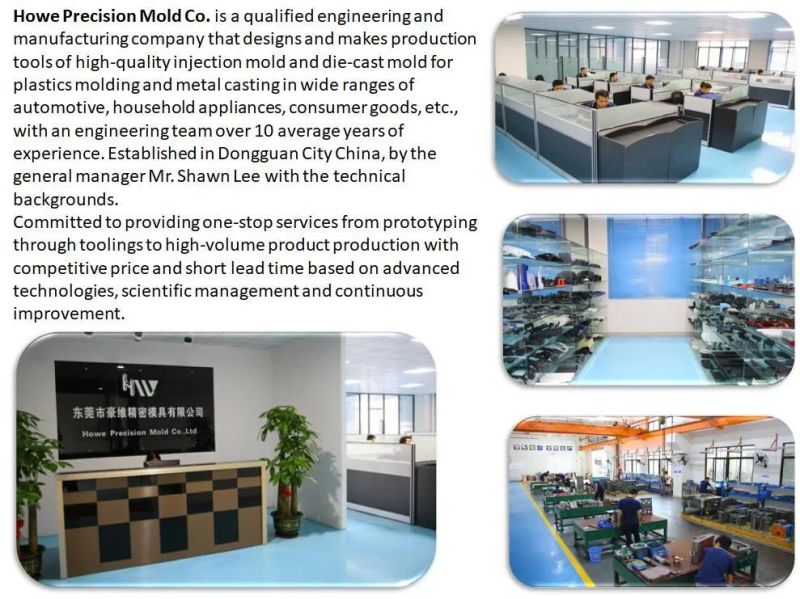

Company profile

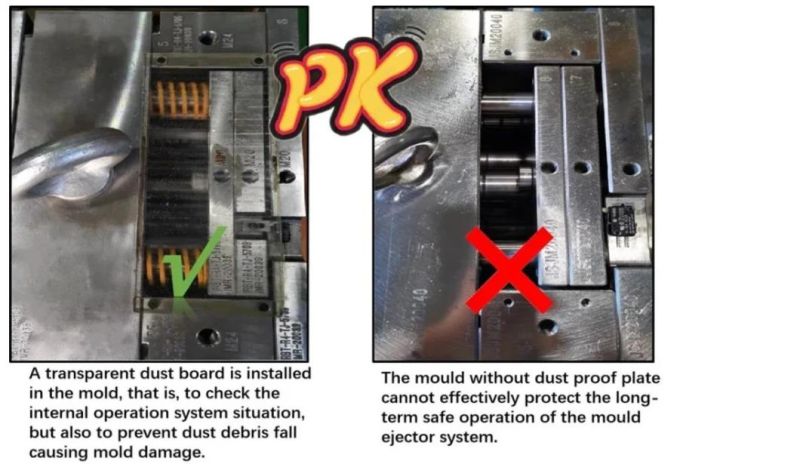

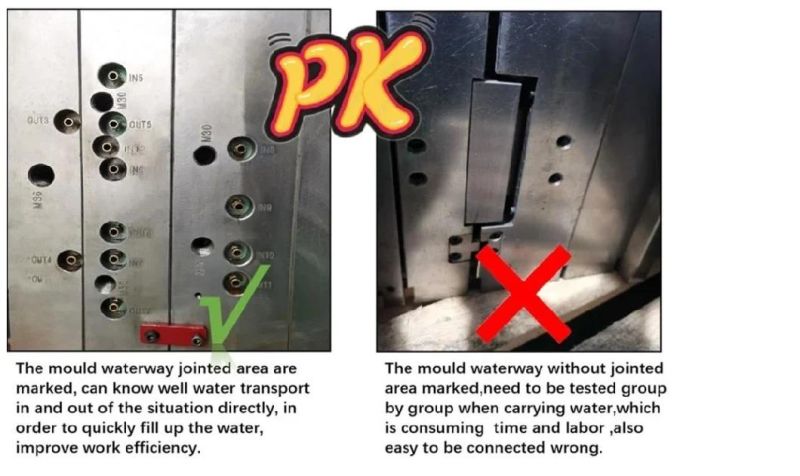

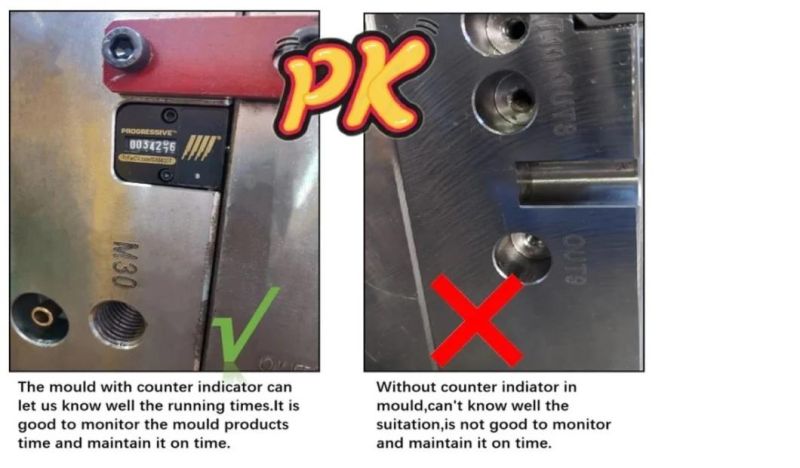

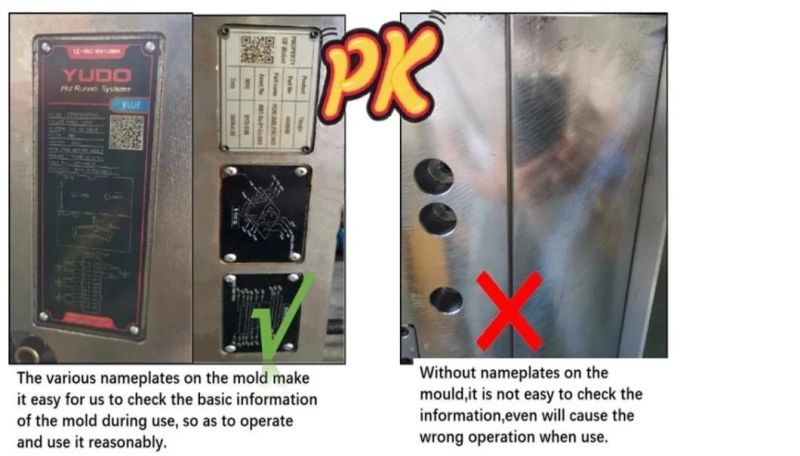

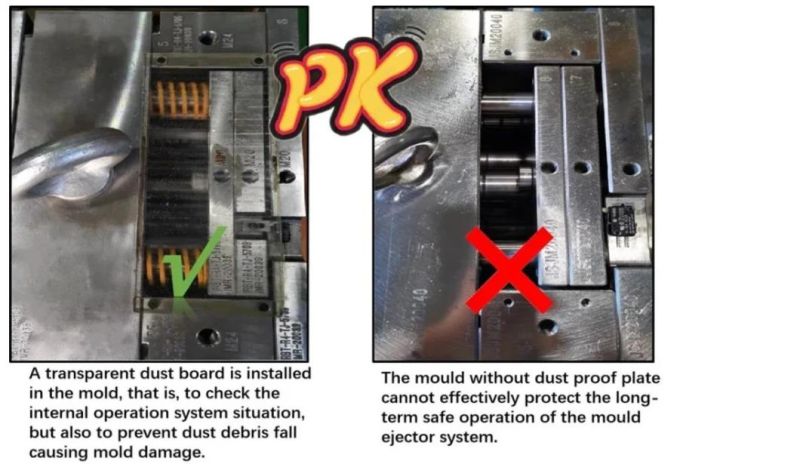

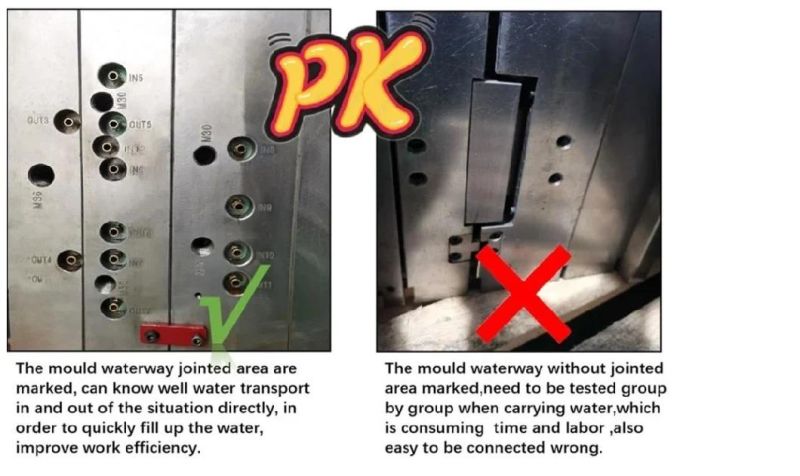

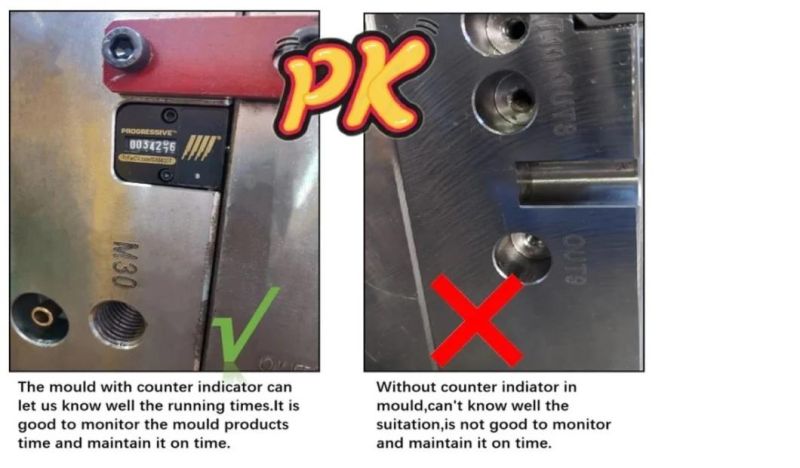

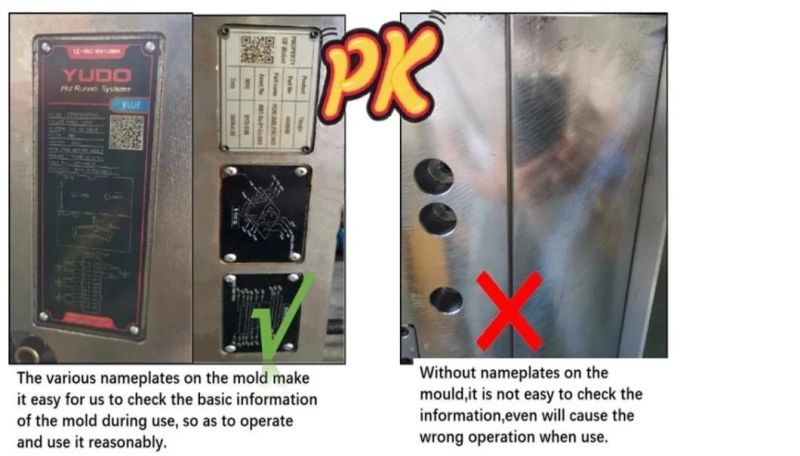

Quality Control

Quality Control

Service

1.CNC Plastic/Metal Prototypes | | 2.Vacuum casting/vacuum forming(Silicon Mould) |

| 3.Low Volume Production |

| 4.Rapid Hardware/Sheet Metal Prototypes |

| 5.CNC Aluminum/Brass/Copper/Bronze CNC machining/machined parts |

| 6.Automotive and medical equipment Prototypes |

| 7.SLA/SLS prototype |

| 8.Metal Stamping&NCT Stamping |

| 9.3D Printing |

| 10.Die-casting, hardware machining |

| 11.Electronic Manufacturing Service |

| 12.Injection mould&Plastic Injection |

| 13. Lathing parts |

| 14.Design service (OEM service) |

| Certification passed | Bureau Veritas,ROHS,ISO |

Packaging & Shipping FAQ

FAQQ: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: If you make poor quality goods,will you refund our fund?

A: As a matter of fact, we won't take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.

For more information, please contact us ! Thanks !