Blow Molding of Pet Bottle Mould

Dongguan Ace Plastic Hardware Products Co., Ltd.- Gate Type:Direct Gate

- Shaping Mode:Blowing Mould

- Material:Plastic

- Application:Commodity, Household Appliances, Electronic

- Runner System:Hot Runner

- Cavity Quantity:1

Base Info

- Cooling:Baffles,Sprin Piple,3D Printing Water Line

- Design Capability:Mould Flow Analysis

- Design Software:Data Exchange: Ug, PRO,E, Solidworks, Caita, CAD

- Standard Parts/Cylinders:Dme,Hasco,Progressive,Misumi,Parker,HP,Merkle

- Multi Injection:Single,Double,Multi Color

- Standard Delivery:40 Days or 5 Weeks

- Part Size Range:Part Size up to 2.5 Meter Blow Injection Molding

- Surface Requirement:Texture EDM Spi Chrome Coating

- Ejector System:Pin,Air Valve,Stripper Plate

- Cavitation:Single ,Mutil Cavites

- Plastic Part Resin:PP PC PMMA ABS Acrylic

- Plastic Part Name:Pet Injection Blowing Molding

- Customized:Customized

- Certification:CE

- Injection System:Hot Runner ,Cold Runner

- Transport Package:Standard or as You Request

- Specification:Plastic

- Trademark:ACE

- Origin:Guangdong China

- Production Capacity:100000 Piece,Pieces Per Month

Description

Plastic Part Nameinjection molding machine Injection System Hot runner /Cold Runner Surface Requirement Texture EDM SPI Chrome Coating Cavitation Single /Mutil Cavites Plastic Part Resin PP PC PMMA ABS Acrylic Ejector System Pin/air Valve/Stripper plate Tolerance Request Up to 1mm Steel Standard ASSAB/FINKL/BOHLER/ Groditz/Buderus Production Quantity Up to 100000 PCS Cooling Baffles/Sprin Piple/3D printing water line Part Size Range Part Size up to 2.5 meter blow injection molding Standard Delivery 40 days or 5 weeks Multi Injection Single/Double/multi color Standard Parts/Cylinders DME/HASCO/PROGRESSIVE/MISUMI/Parker/HP/Merkle Design Software Data exchange: UG, PRO/E, SOLIDWORKS, CAITA, CAD, STP, X_T, IGS, PRT, DWG, DXF Design Capability DFM,Mould flow analysis,Product optimization, Full 2D & 3D mould design,Reverse engineering,Collaborative design with customer's idea Quality Assurance Design Control, Steel Hardness Inspection Report, Steel Dimension Control Report, Mold Core and Cavity Dimension Inspection Report Documents / Reports Provided Fully drawing,Weekly Processing Report, Steel Dimension report, Processing Report,Sample Dimension Report.

ACE has been a key supplier to some of the most well known Blow molding OEMs ACE's infrastructure of complete resources allows our clients To focus on what's most important to the Blow molding market-zero defects, and lowering overall costs.

We are able to built the Blow molding parts as follows:

*PET injection blow molding

*Thin wall blow molding

*Large size blow molding

*Blow Mold and Blow molding

*Lighting and Lamp blow molding

*High Weight Blow and injection molding

DepartmentMajor Equipment Name Specification Unit Total Mold Department CNC Machining Center ROEDERS RFM-800 Precision Centre Made in Germany 36000/min 2 14 CNC Machining Center ROEDERS RXP-500 Precision Centre with Renishaw online inspection Made in Germany 50000/min 2 CNC Machining Center ROEDERS RFM-600 Precision Centre with Renishaw online inspection Made in Germany 42000/min 2 CNC Machining Center ROEDERS RFM-600 Precision Centre Made in Germany 42000/min 2 CNC Machining Center KT-600II Precision Centre 24000/min 4 CNC Machining Center Shenghong taiwan 8500 2 Electric Discharge Machine(EDM) SODICK EDM Machine AD30L 4 11 SANDY EDM Machine ED3 2 Wintop 350 3 Wintop DE -650 2 Milling Machine Milling machine 16SS 8 9 Mazak Milling machine QTN150 1 Cutting Machine Cutting machine MV1200S 3 3 Drill Press Machine Drill Press machine Z3032X10 1 1 Molding Department Plastic injection machine Injection machine Kiaming 58T 1 24 Kiaming 98T 1 Kaiming128T 4 Kaiming 168 T 2 HaiTian 200T 8 Taiwan 250T 1 Toshiba 220T 1 Kaiming 400T 2 Kaiming 450T 1 HaiTian 650T 2 HaiTian 1300T 1 Quality Department Inspection machine 2.5D Video Measuring System VMS-2015F 1 2 Alberlink CMM HR-150A 2 2

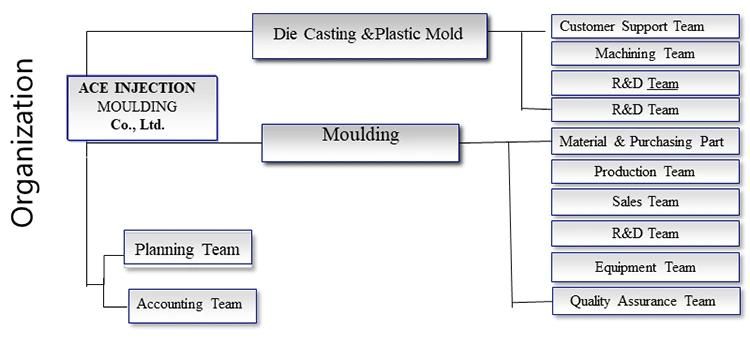

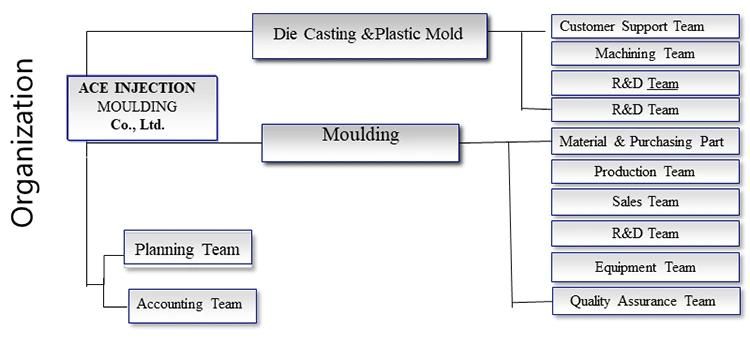

organlzation

Currently possess a strong team with 140 people, including

* 32 Design & Engineers ( ≥ 10 years' experience)

*12 CNC programmers

*8 project engineers

*6 Sales people

*5 full-time quality inspection personnel

*4 people in logistic team

*60 tool makers

*13 Office worker

Our standard packaging for plastic injection mold is wooden pallets or wooden cases.

Other Products

Our website lists some of our successful products, but please note that this is just one example on behalf of our products and services, so if you can't see the products you want, please contact us immediately. We warmly welcome customers all over the world and are looking forward to establishing a steady and long-term business relationship with you .

F A Q

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, Alibaba,Alibaba TradeManager, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don't have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How do you deliver the goods?

A: We have our own logistics department that could provide shipping costs via Sea or Air freight, Incoterms EXW, FOB, DDP, DDU etc. Or we can work with your appointed shipping forwarder.

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

CONTACT US

ACE has been a key supplier to some of the most well known Blow molding OEMs ACE's infrastructure of complete resources allows our clients To focus on what's most important to the Blow molding market-zero defects, and lowering overall costs.

We are able to built the Blow molding parts as follows:

*PET injection blow molding

*Thin wall blow molding

*Large size blow molding

*Blow Mold and Blow molding

*Lighting and Lamp blow molding

*High Weight Blow and injection molding

Department

organlzation

Currently possess a strong team with 140 people, including

* 32 Design & Engineers ( ≥ 10 years' experience)

*12 CNC programmers

*8 project engineers

*6 Sales people

*5 full-time quality inspection personnel

*4 people in logistic team

*60 tool makers

*13 Office worker

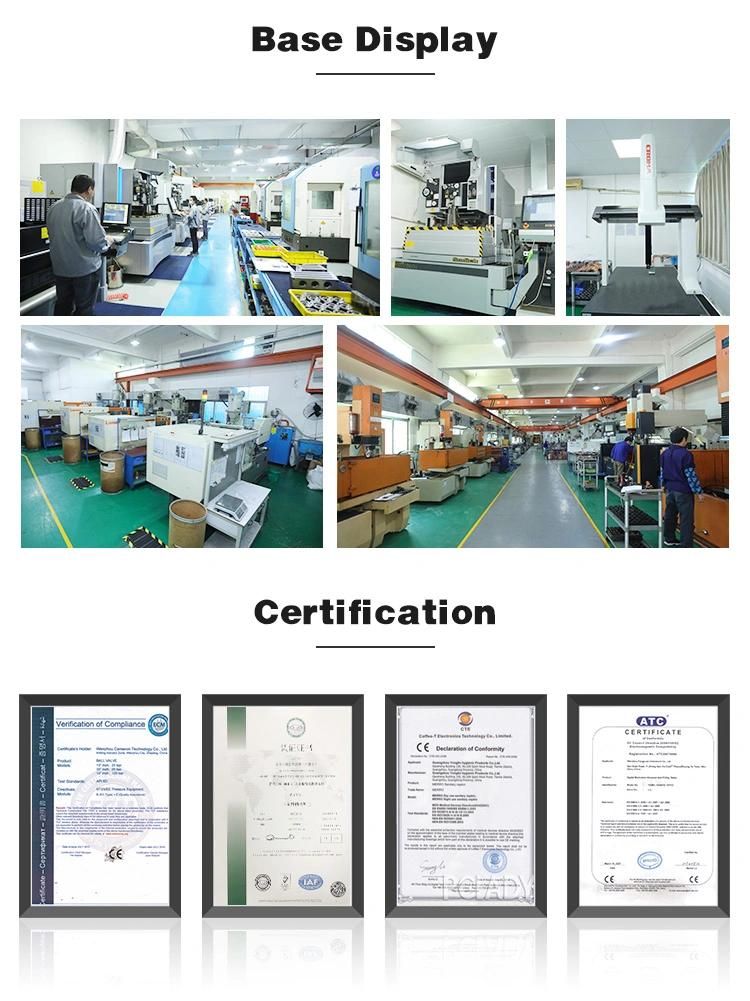

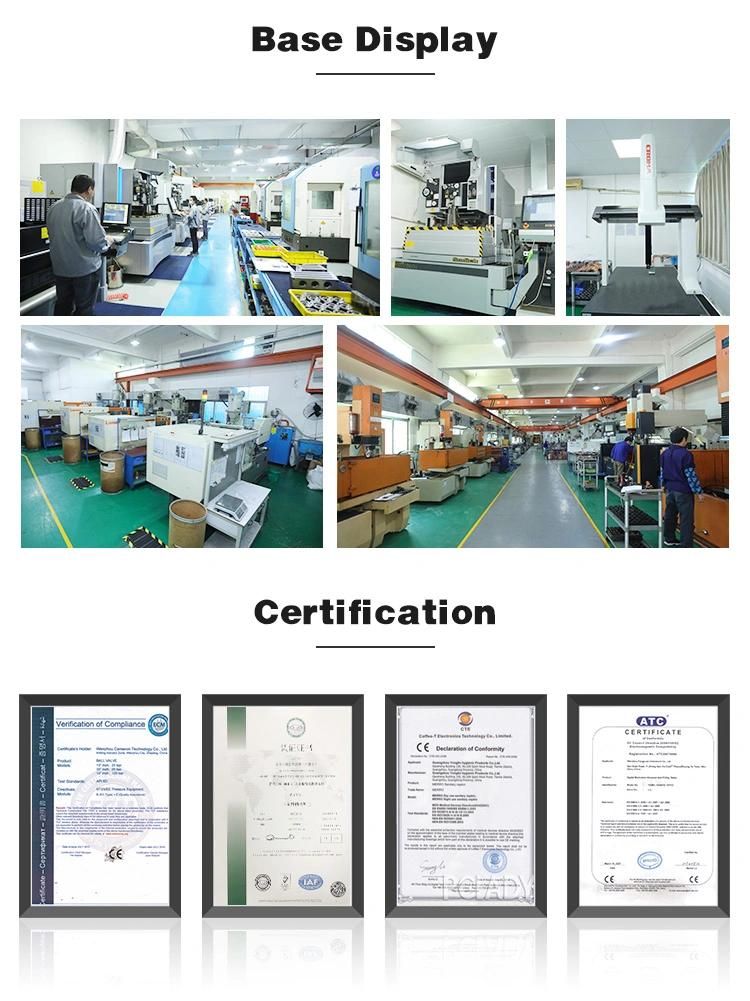

Workshop

Our factory is under ISO standards & certification.This insures productivity and total control on quality.

Packaging &Shipping

Our standard packaging for plastic injection parts we use PP bag plus cardboard boxes or as per customer requirements.Our standard packaging for plastic injection mold is wooden pallets or wooden cases.

Other Products

Our website lists some of our successful products, but please note that this is just one example on behalf of our products and services, so if you can't see the products you want, please contact us immediately. We warmly welcome customers all over the world and are looking forward to establishing a steady and long-term business relationship with you .

F A Q

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, Alibaba,Alibaba TradeManager, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don't have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How do you deliver the goods?

A: We have our own logistics department that could provide shipping costs via Sea or Air freight, Incoterms EXW, FOB, DDP, DDU etc. Or we can work with your appointed shipping forwarder.

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

CONTACT US