Used Long Tail Pet Plastic Preform Mould with Hot Runner Injection Plastic Preform ...

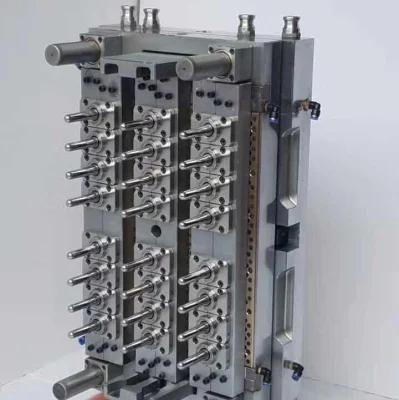

Taizhou Shuoqu Machinery Co., Ltd.- Cavity Quantity:2.4.8.12.16.24.32.48.72

- Runner System:Hot Runner

- Shaping Mode:Injection Mould

- Material:Steel

- Customized:Customized

- Installation:Fixed

Base Info

- Origin:Huangyan Taizhou Zhejiang

- Transport Package:Wooden Packing

- Model NO.:PCO 1810

Description

Basic Info.

Model NO. PCO 1810 Transport Package Wooden Packing Origin Huangyan Taizhou ZhejiangProduct Description

PCO 1810 PET preform mould

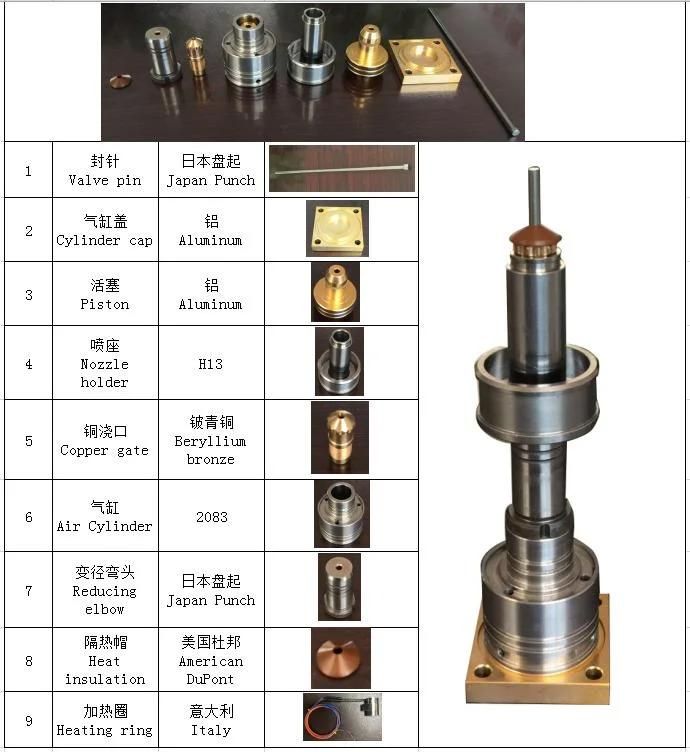

Features of PCO 1810 PET perform mould:

1. Mould plates are P20 steel with pre-hardening process. Core, cavity and neck screw are made of S136 high strength anti-corrosive stainless steel, which is better than 48HRC.

2. Mould plate is completed by one-time processing to ensure the concentricity of molding hole and guide bush, guaranteeing the compact structure of the mould.

3. Opening/closing pulling plate(material S136) adopts bearing slide type to drop the perform with reliable structure. And it is a highly integrated process of slider, pushing plate and ejection. All sliding parts surface inlaid self-lubricating copper alloys to ensure low friction coefficient and strong wear-resistant.

4. The main components are consistent with various well-known foreign brands, high positioning accuracy and convenient disassemble.

5. Reasonable and quick spiral cycle waterway can get rapid cooling effect to shorten cycle time.

6. Adopting double cone positioning principle guarantees high manufacturing precision to ensure the product does not appear flash, different sizes, irregular and other defects.

7. Neck screw is processed by famous brand equipment. The dimension is accurate and consistent.

8. Moulding part hardening makes the friction surface stable, identical and durable in use.

EXCELLENTAfter years of development and experience accumulation,Shuoqu has advanced experience mould manufacturing and R&D management.We have an excellent technical team to provide customers in with high quality and efficient service.

We have advanced precision mould processing equipments, multistage taper positioning system to ensure the thickness of the product is consistent,the shape of the product is optimized according to the plastic bottle sample to ensure the final product molding quality,as well as the standard production workshop.And after years of optimization and improvement of the processing technology,as well as perfect processing operations instructors,laid a good foundation for the manufacture of high-quality moulds.