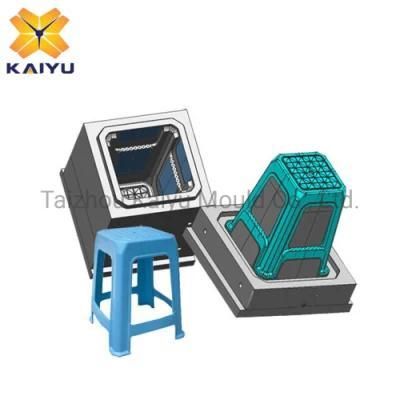

Taizhou Huangyan Plastic Chair Mold Professional Injection Plastic Mould for Chair

Taizhou Kaiyu Mould Co., Ltd.- Process Combination Type:Progressive Die

- Plastic Material:ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Mirror Polishing

- Shaping Mode:Injection Mould

- Application:Commodity, Home Use

Base Info

- Transport Package:Wooden Case

- Demoulding Method:Full Automatic

- Ejection Method:Stripper Plate with Air

- Surface Treatment:High Glossy Polishing

- Mould Life:1 Million Shots

- Mould Material:718

- Name:Plastic Chair Mould

- Customized:Customized

- Standard:HASCO

- Certification:SGS

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:kaiyu-202054

- Specification:2344steel

- Trademark:KAIYU

- Origin:China(Mainland)

- HS Code:8480710990

- Production Capacity:500

Description

*Excellent cooling system

*Uniform wall thickness,the product is not deformed,a high modulus

*Highly polished surface or mould inner surface coating for better release

*No bubbles,no scorched marks

* Advanced manufacturing and testing equipment

*Exquisite processing technology

*Perfect product-mould line

1).Product Design

Customer send us the product drawing directly or we draw the product

according to the sample,then we send customer the product drawing to confirm

2). Mould Design

We'll start to design mould after the product drawing confirmed,then

send customer the mould drawing to confirm

3). Mould Making

The mould start to make after the mould drawing confirmed,the process

include prepare steel,rough cut,finish machining,assembly etc

4). Mould Test

we'll test the mould after mould assembly,then we'll send customer samples

and video of mould test to confirm

5). Final Process

The mould start to polish if the sample is ok,and make grain,nitridation or

chroming if customer required

6). Mould Test

We'll test the mould again after polishing,then send customer the final

sample and video of mould test to confirm

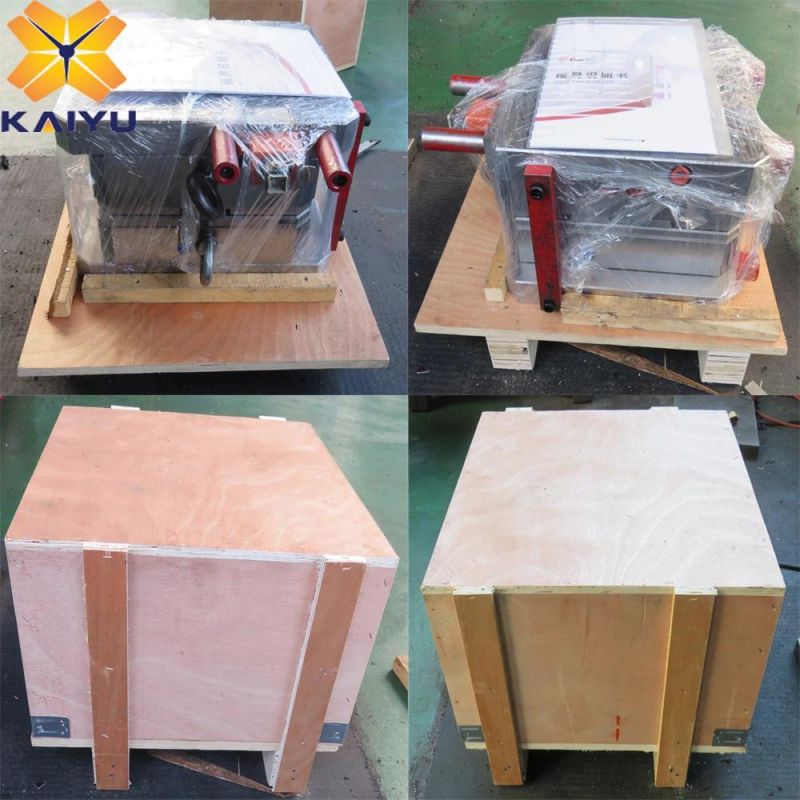

7). Mould Packing

The mould stard to pack with wooden case after the final sample confirmed,

then the mould will be sent to port and waiting for shipping

Packing Details

1.Check plastic injection mould component

2.Cleaning mould cavity/core and spread slushing oil on the mould

3.Cleaning mould surface and spread slushing oil on the mould surface

4.Put into the wooden case

FAQ

A:Which kind information need for quotation in KAIYU MOULD?

1,Sample photo with size or 2D/3D design

2, Cavity quantity

3, Runner type, cold or hot

4,Mould steel type,

P20, 718, 2344,H13,S136,2316,and so on.

5,Injection machine parameter or plate size(tie rod distance)

B:Delivery time in KAIYU MOULD

3~15 days for mould design, 15~60days for mould production after deposit payment and mould design confirmed

C:Payment Terms in KAIYU MOULD:

TT, L/C, Western Union, Paypal

D: Shipping Type in KAIYU MOULD:

By Air Or By Sea

E:Guarantee in KAIYU MOULD

One year guarantee

Why Choose KAIYU MOULD?

Kaiyu Mould Factory is the leading plastic mould manufacturer in China, based on precise tooling, high technology and top mentality mould design.

1.Design

We are professional for mould design, our technique absorbed from Taiwan and Europe.

2.Quality

All of our mould steel have certificate with longer mould life, mould produced by advanced equipment, the tolerance can reach +/-0.01mm, the molded product have good appearance ,without any flash and good fit with other products.

3.Price

We always provide competitive price, because of we are manufacturer, we are the source.

4.Service

Free product design&mould design 2D/3D.

Free sample delivery, 3 times mould test.

Every week update production informations.

Mould one year quarantee,Mould full-life technique support.

Contact Us