Custom Precision Plastic Injection Mould Design for Coupling Tee PPR Pipe

Qingdao Chuangyu Precision Machinery Co., Ltd.- Surface Finish Process:Anodizing

- Mould Cavity:Custom Cavity

Base Info

- Transport Package:with PE Plastic Packed Then Into The Wooden Box

- OEM:Yes

- ODM:Yes

- Material:Stainless Steel,Metal Ect

- Polish:High Polish

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Cold Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:HDPE

- Model NO.:CM01

- Specification:up to design

- Trademark:Chuangyu

- Origin:China

- HS Code:8480419000

- Production Capacity:20pieces,Month

Description

Metal Machinery Parts:

Except mold making, we also make machinery parts for Household Appliances/ Car/ Commpdity/ Home Use/ Electronic/ Offical Equipment/ Medical Apparatus ect.

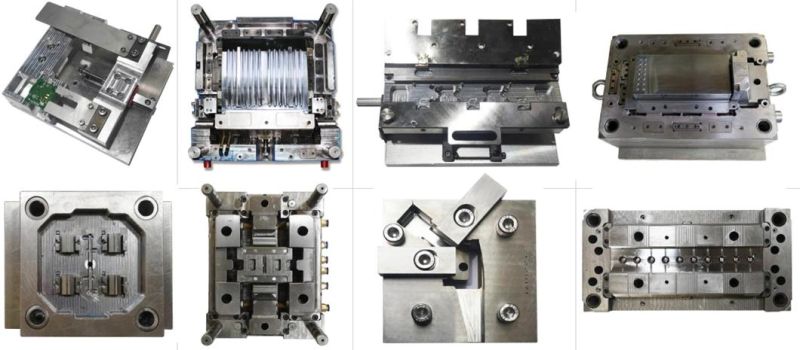

Mould Display:

We are a very strong and professional factory, we made many moulds for many big companies and work with them for so many years, such as Haier, we have our own design team in their company as to design for them special, we pay high attention to the mold's precision as to meet our client's requirement.We also have the professional QC team to check the mold and machinery parts before shipment as to avoid any mistake.

Shipment:

We usually delivery the moulds and machinery parts by sea/DHL/FEDEX/TNT, according to the customers.

Factory:

1: We could make ODM/OEM products, we have our own R&D team that each of them has over 7years rich experience.

2: We could make almost all the material to meet client's different needs, such as ABS/PP/Aluminum/Stainless steel/Titanium ect.

3: Surface treatment: anodizing, powder coating ,polishing, electrophoresis, chemical galvanizing etc.

4: Finish: polished,mirror polished,brushed, sandblasted, heat treatment etc.

5: Color: anodized(black,silver,blue,gold,red,green,pink etc.), painting(all colors)

6: Logo Method: laser engraving, CNC engraving, screen-printing etc.

1. Basic Information

Mold type: all tyes of produts plastic mould

Mould base material: #45.LKM, LYM standard etc

Mould spare parts material: Jinghong, HASCO, DME etc

Hardness of steel: 28-55HRC

Mould design: 3D/2D drawings

Runner: cold runner

Design days: 1-3days

Mould life: 500,000-3,000,000 shots

Plastic material: PE, PC, PS, PP, PA, ABS, etc

Injection system : pin point gate

2. Quality Reference

Level A: 1,000,000 shots - high

Level B: 800,000 shots - middle

Level C: 500,000 shots - normal

3. Application

Communication/Electronic/Auto parts/Surveillance products/Medical device/equipment and so on

4. Customers assistance for initial detailed quotation on plastic injection molding

1) 2D/3D Design drawings offered

2) If there is no drawing, please advise the dimension/photos with dimension

3) Material information

4) Level and quantity information if possible.

FAQ:

1. Q: what is the processing for the quote ?

A: We can quote from your 3d formats like IGS,STP,PARASOLID etc and 2D drawings as well; quote the price to clients after got the 2d or 3d drawings within 2 hours;

2. Q: How is the next ?

A: We will send the cost to you and get your confirmations for the quote;

3. Q: what is the software will you use for the proceeding ?

A: We make the 3D programm with Pro-Engineer, UGS, SOLIDWORKS, MASTERCAM etc ;

4. Q: what is the type of machines for manufacturing ?

A: Manufactured from CNC Machining, Laser cutting , stamping ,injection as well as the parts files different ;

5. Q: Do you do the surface treatments please ?

A: Yes, sure. we do the surface treatments, for instance: chromated, powder coating, Anodizing, laser etching as well as painting ;

6. Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping;

Why choose us?

1. We have more than 10 years experience for production

2. We have an extensive expertise in CNC machining, offer "One-stop Service".

3. Now we have more than 35 sets of various processing equipment. There are 15 people in professional technology, R&D team.

4. All of our operations are strictly compliant with ISO 9001: 2015 guidelines.

5. One of our staff is settled down in Germany as to offer better service to our clients.

If you have any doubts, please contact me freely.