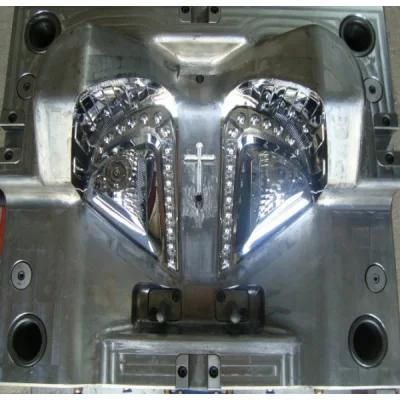

Injection Mold for The Auto Lamp

Yuyao Xianghao Mold Technology Company Limited- Surface Finish Process:Polishing

- Mould Cavity:Multi Cavity

Base Info

- Transport Package:Steel Box

- Plastic Mould:Plastic Injection Mold

- Customized:Customized

- Plastic Mold:Injection Mold

- Standard:DME

- Certification:TS16949

- Installation:Mobile

- Design Software:UG

- Runner:Hot Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:HDPE

- Model NO.:injection mold

- Specification:SGS

- Trademark:darrow

- Origin:Yuyao

- HS Code:8480710090

- Production Capacity:100sets,Month

Description

Basic Info.

Model NO. injection mold Plastic Material HDPE Process Combination Type Single-Process Mode Application Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware Runner Hot Runner Design Software UG Installation Mobile Certification TS16949 Standard DME Customized Customized Plastic Mold Injection Mold Plastic Mould Plastic Injection Mold Transport Package Steel Box Specification SGS Trademark darrow Origin Yuyao HS Code 8480710090 Production Capacity 100sets/MonthProduct Description

Plastic mold /mould

Mold mould

Progressive die material for car exhaust pipe

Material: Metal

Surface Finish: Degreasing

Part Request: There are not indentation, scratches, oxidation on the surface, 120h salt spray without rust.

Mould Info:

Lead Time: 40 days

Mould Type: Progressive die

Mould material: SKD11

Design software: Auto CAD, PRO/e, UG.

Hardware Die Processing Flow Chart:

1. Mould design 2. Rough finish 3. Heat treatment 4. Wire cutting 5. CNC machining 6. EDM machining 7. Mould assembly 8. Mould trial run until approval

Hardware Product Processing Flow Chart:

Stamping--- tapping --plating --- checking --- packing

The main processing production equipments and the business scope as follows:

1. Different size of CNC high speed cutting processing center and CNC high speed milling machining center.

2. Turning, milling, drilling holes, some high precision and more complex curved surface as customized.

3. Different kinds of wire -cutting machine and different size of EDM machine.

4. Wire -cutting machine from Japan and Switzerland are mainly used to process template and mould accessories.

5. Grinding (center grinding and centerless grinding )for precision inner and outer diameter, grinders and deep hole drilling machine work coordinately to process the large moulds.

6. We have 30 sets plastic injection machine and 30 sets press machine.

7. We have 14 years' processing experience and can produce different kinds of plastic and hardware products, mould and mould accessories.

| Experience | Over 13 years experience in metal stamping parts which cover more than 7000 square meters. |

| Certificate | ISO9001:2008, RoHS |

| Material | stainless steel, iron (SPCC, SECC, SPTE, tinplate), aluminum alloy, red copper, brass, bronze alloy. etc. are available |

| Process | stamping, deep drawing, welding, Bending, sheet metal fabrication, and metal assembly. etc |

| Surface treatment | nickel plating, zinc plating, color zinc plating, acid pickling, silver plating, chromium plating, polishing, Surface spraying |

| Application | temperature controller, mutual inductor, relay, sound, car GPS, Car chargers, ships, home appliances etc |