Plastic Injection Moulding and Plastic Injection Mold Maker Factory

Dongguan Yixun Industrial Co., Ltd.- Plastic Material:ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Process Combination Type:Progressive Die

- Application:Commodity

Base Info

- Trademark:YiXun

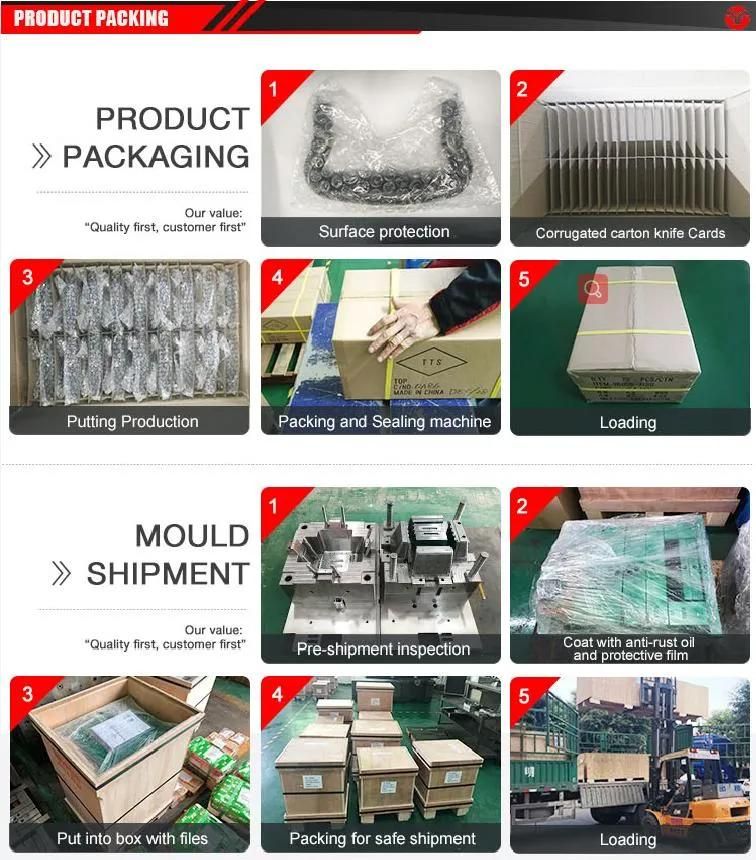

- Transport Package:Plywood Box

- Customized:Customized

- Standard:HASCO

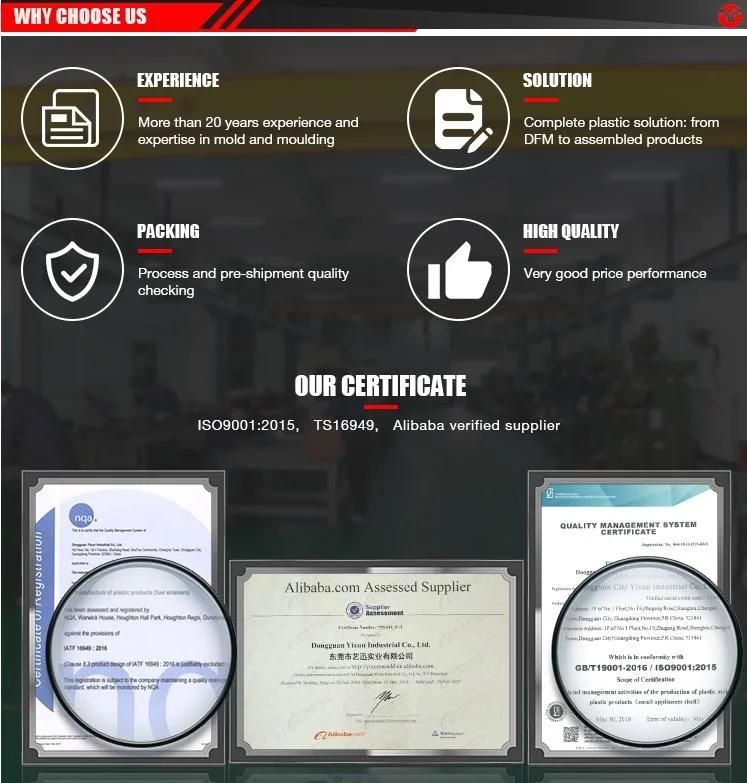

- Certification:TS16949, ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Hot Runner

- Model NO.:Mi051

- Origin:China

- HS Code:8480710090

- Production Capacity:50sets,Month

Description

Basic Info.

Model NO. Mi051 Runner Hot Runner Design Software Pro-E Installation Fixed Certification TS16949, ISO Standard HASCO Customized Customized Transport Package Plywood Box Trademark YiXun Origin China HS Code 8480710090 Production Capacity 50sets/MonthProduct Description

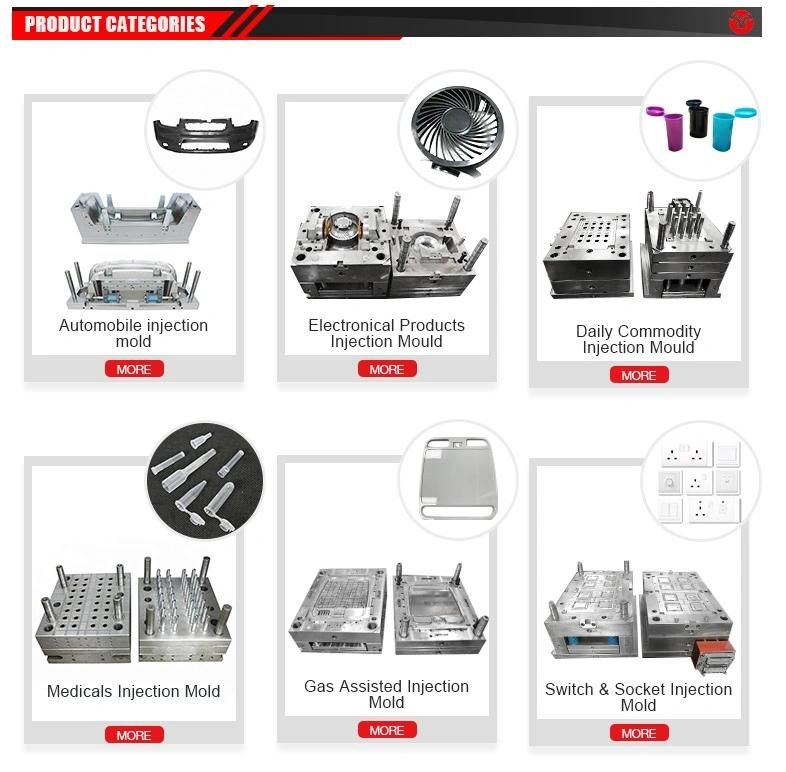

Dongguan YIXUN Industrial Co.,Ltd is a high technology company,specializing in many kinds of plastic mold designing,manufacturing and injecting,mainly covering the enclosure and part of automobile,electrical,printer,commodity,electronic etc.

Dongguan YIXUN Industrial Co.,Ltd is a high technology company,specializing in many kinds of plastic mold designing,manufacturing and injecting,mainly covering the enclosure and part of automobile,electrical,printer,commodity,electronic etc.YiXun has 2 manufacturing facilities, totally 12,000 square meters, 260 employees, 90% of them has experience over 10 years.

YiXun yearly capability is up to 600 sets mold per year, the biggest reach 25 tons.

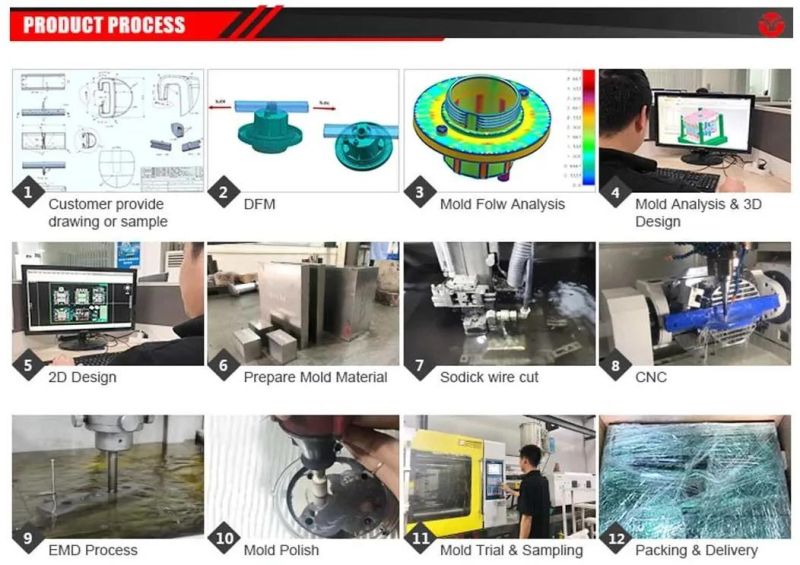

YiXun adopt the up-to-date design software, such as Auto CAD, UG, Pro/E, Solid Works etc, Mould standards such as DME, HASCO, FUTABA, LKM and so on.

YiXun has a full set advanced mould manufacturing equipment, 8 sets CNC machines, 15 sets EDM machine, 3 sets middle speed Wire Cut Machine, 2 sets slow speed Wire Cut Machine, 15 sets Milling Machine, 4 sets lathe machine, 2sets mold die fitting machine,17 sets injection machine from 35 tons to 818 tons.

Mold FAQ

Q:How about your quality control?

A:We have professional team to control mold quality, since we realize that quality control is the first priority to run business.

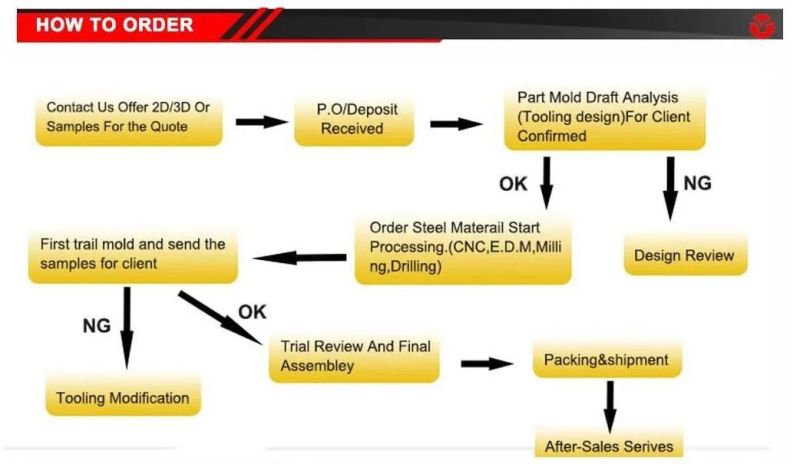

Q:What's your lead time?

A:For most mold, 45 to 60 working days ( not including Chinese official holidays ) after deposit received and mold drawings approved.

Q:How long can i get the sample?

A:Depends on your specific items,within 3-7 days is required generally.

Q:What about after service?

A:Spare part which is non-man made damaged will be offered for free within one year, and you can contact us at any time if you need help.