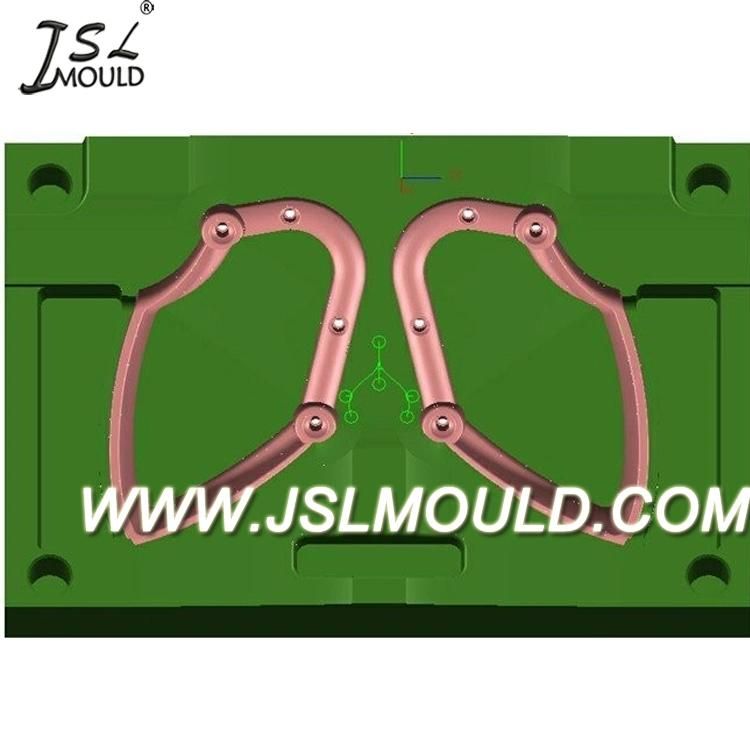

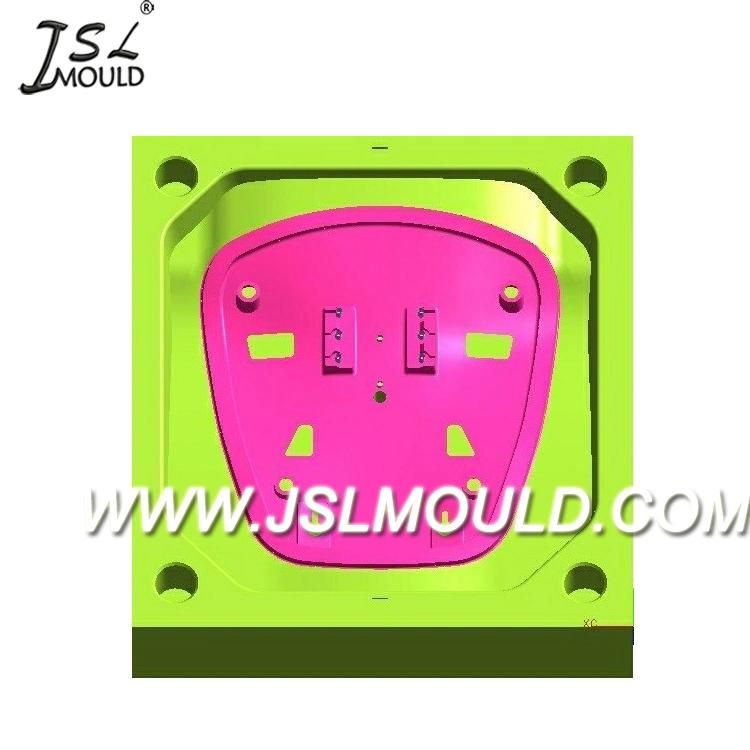

Plastic Office Chair Mold

Taizhou City Huangyan Beiwei Mould Industry Co., Ltd.- Plastic Material:PA

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:1 Year

- Process Combination Type:Single-Process Mode

Base Info

- Time of Warranty:1 Year

- Quality Control:Professional QC in House

- Design Time:7days

- Mould Running:Full Automaticity

- Heat Treatment:Nitriding

- Machine Equipment:CNC,EDM,Wire Cutting Machine,Drilling Machine

- After-sales Service:2 Years

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Ug,Proe,CAD,Catia,Solidworks

- Runner:Hot Runner

- Application:Furniture

- Model NO.:J1903291

- Transport Package:Wooden Case

- Specification:Dme

- Trademark:JSLMOULD

- Origin:China

- HS Code:8480719090

- Production Capacity:300sets,Year

Description

Basic Info.

Model NO. J1903291 Application Furniture Runner Hot Runner Design Software Ug,Proe,CAD,Catia,Solidworks Installation Fixed Certification ISO Standard DME Customized Customized After-sales Service 2 Years Machine Equipment CNC,EDM,Wire Cutting Machine,Drilling Machine Heat Treatment Nitriding Mould Running Full Automaticity Design Time 7days Quality Control Professional QC in House Time of Warranty 1 Year Transport Package Wooden Case Specification Dme Trademark JSLMOULD Origin China HS Code 8480719090 Production Capacity 300sets/YearProduct Description

Product Name:Plastic Office Chair MoldProduct material: PP,PA

Core&Cavity Steel: 718

Steel hardness: HRC35-38

Mould Standard: DME

Cavity Number: ONE

Injection System: SIDE GATE

Ejector System: EJECTOR PIN

Cycle Time: 30~40S

Tooling lead time: 60DAYS

Mould life: More than 500, 000SHOTS

Quality assurance: ISO9001

Our Advantage

1. High quality

2. Reasonable price

3. On time delivery

4. Good After-sale service

5. Strict quality control

6. All the mould are automotic.

Offer you

In-time response on letters, telephone calls or fax

In-time supply the quotation and mould designs

In-time communication on the technical points

In-time sending pictures for the mould machining progress and mould finishing schedule

In-time mould test and sample delivery

In-time mould delivery.

For more information please contact us.

1.Offer you mould core & cavity steel certificate

2.Offer you mould trial video

3.Mould process report

Weekly report, mould trial video and samples for your checking

4.Spare parts

wearing spare parts provided

Design Software:UG,PROE,CAD,CATIA,SOLIDWORKS

Heat Treatment:Nitriding

Mould design: 7days

Our target:Save every pennny for client

Quality control: Professional QC

Machine Equipment:CNC,EDM,Wire cutting machine,Drilling machine

Mould running: Full automaticity

Mould steel:S136,NAK80,AISIP20,DIN1.2311(P20),DIN1.2344, DIN1.2738,H13,718H,2316 etc.For your choice.

Plastic material

PP, PC, PS, PE,PVC, ABS, PMMA,TPE ect.