Cemented Carbide Pellets for Cold Formimg

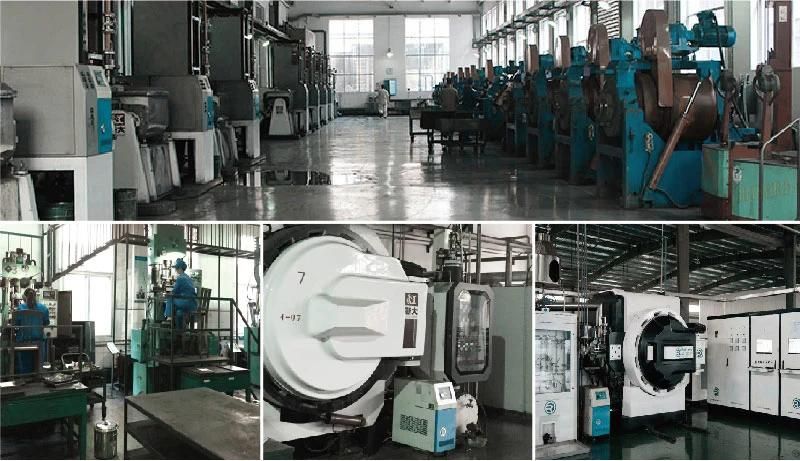

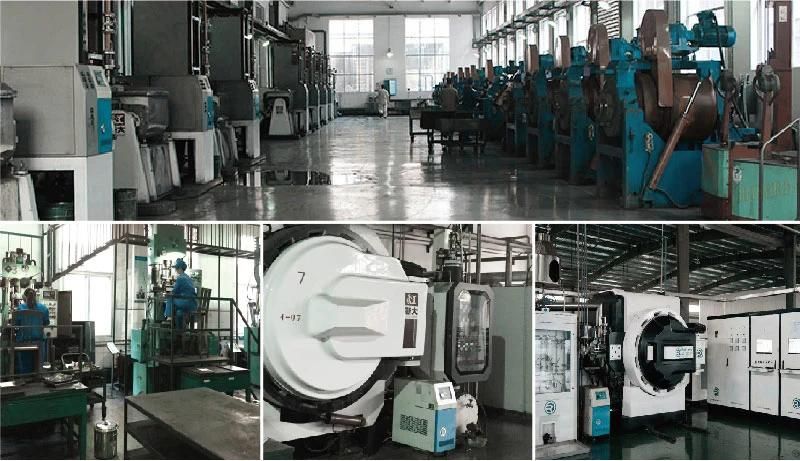

Zhu Zhou Evergreen Hardmetal Tools Co., Ltd.- Process Combination:Progressive Die

- Technics:Forming Die

- Processing Method:Punching and Shearing Mould

- Material:Tungsten and Cobalt

- Application:for Punching

- Manufacturing Technology:Automation Technology

Base Info

- Specification:tungsten and coblat powder

- Transport Package:Small Boxs Within One Carton

- Parts Detection Method:Geometric Detection

- Milling Speed:High Speed

- Mold Cavity Technology:The Traditional Forming Electrode Machining

- Driving Motor Type:Permanent Magnet

- Trademark:Evergreen

- Origin:China

- HS Code:8466910000

- Production Capacity:5tons Per Month

Description

For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps.YG16C 13.9 2900 85.5 Impact resistance forging dies. G18C 13.7 3100 84.5 Impact resistance forging dies, hot-press forging dies and rollers. YG20C 13.5 3300 83.5 Dies for wear resistant or impact resistant application. YG22C 13.3 3500 83 Nut forming dies and high impact resistance forging dies YG25C 13.1 3600 82.5 Stainless bolt header dies and rollers.

Contact way;

Jennifer wong

| Dim.of d1 | ≤0.5 | >0.5-2.0 | >2.0-3.2 | >3.2-6.0 | >6.0-12 | >12-25.0 | >25.0-up |

| Tolerances | 0 -0.01 | 0 -0.015 | 0 -0.02 | -0.01 -0.03 | -0.01 -0.04 | -0.02 -0.06 | -0.03 -0.10 |

Contact way;

Jennifer wong