Making Plastic Injection Mould of ABS/PS/PP Housing for Connector

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:TPE

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Glossy or Mirror Polished, Textured

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Specification:According to customers′ drawings

- Transport Package:Wooden Case for Moulds, Cartons for Parts, or as Y

- Customized:Customized

- Certification:CE, ISO

- Standard:HASCO

- Installation:Semi Fixed

- Design Software:Ug, Autocad

- Runner:Hot Runner

- Model NO.:HW-201012-1

- Trademark:HOWE,OEM

- Origin:Dongguan, China

- HS Code:8480719090

- Production Capacity:300-400 Sets,Year

Description

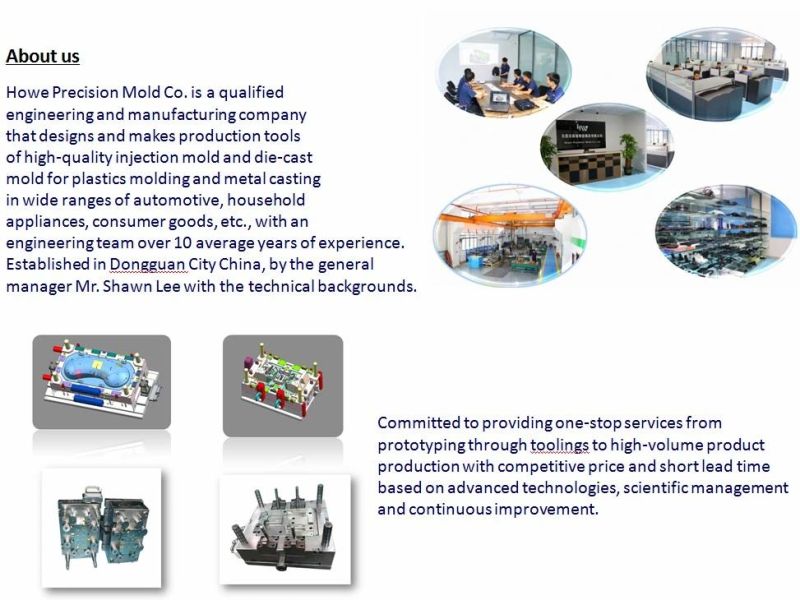

Company profile

Company Profile

Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception.Is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards.Our team of CAD designers will ensure that your imagination is incorporated into the actual product! If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!Our products include :

1.Custom Plastic Injection Parts2.Multi-cavity plastic parts

3.High Precision Molds

4.Insert & over molding

5.Double Shot Mold(2K mold)

6.Unscrewing Molding

7.Gas-assisted Molding

8.Die Casting Molding

9.Prototype plastic parts and Low cycle plastic parts molding

10Gas Assist molding

11.Elastomeric molding

12.IML & IMD part production

13.Thin wall plastic molding

14.High temperature molding

Our workshop

Packaging details

FAQ

| Q1. Are you a factory? |

| A: We are an OEM/ODM mold factory manufacturing plastic injection mold, die casting mold, overmold, double shots mold, and CNC. |

| Q2. Do you making the mold and also producing? |

| A: Both, we making molds and also making production. |

| Q3. How can I get the quotation? |

| A: Please send us 2D/3D drawings with your request for Mold(mold cavity, mold life), we will quote for you within 24 working hours. |

| Q4. I have no 3D drawing, how should I start the new project? |

| A: You can supply us with a sample, and we will help to finish the 3D drawing design. |

| Q5. What is the minimum order quantity? |

| A: No MOQ requirement, Prototype, sample, small batch, and large volumes are all acceptable. |

| Q6. How long is the lead-time for mold? |

| A: It all depends on the mold's size and complexity. Normally, the lead time is 25-35days. If the molds are very simple and with a small size, we can work out within 15 days. |

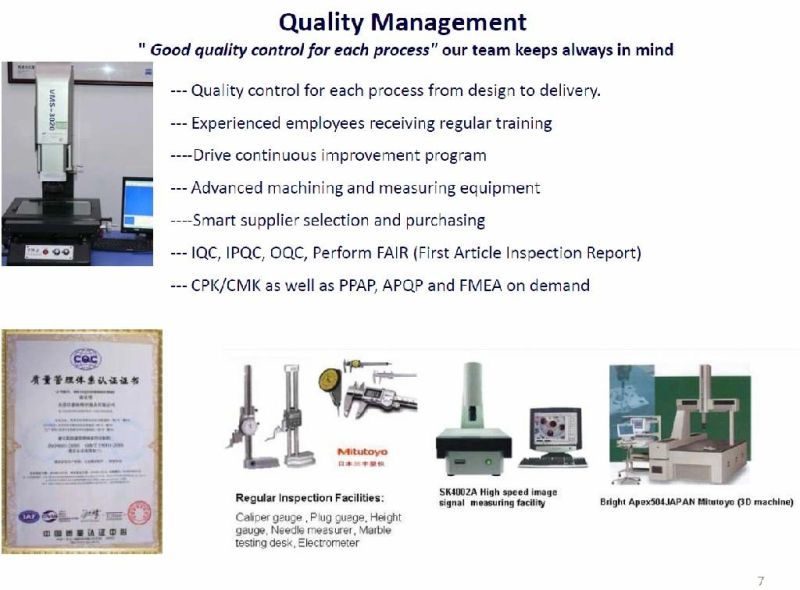

| Q7. How do you ensure quality control? |

| A: We inspect products on every stage of production and ensure 100% output quality thorough QC inspection before shipment. |