-

Different Size Container Box Mold Turnover Box Mould

DescriptionMould Material45#, 50#, P20, H13, 718, 2738, NAk80, S136, SKd61 etcMould BaseLKM, HASCO ect.CavitySingle/multiRunnerHot/coldMould Design3D/2D DrawingDesign Days3 daysDesign SoftwareUG, PROE, CAD, CAE, CAM, CAXA ectPlastic MaterialPP, PC, PS, PE, PU, PVC, ABS, PMMA ectMo uld Life300, 000-3

-

Customized/Designing Aluminum Die Casting Mould for Auto Parts

Basic Info. Model NO. Customized

-

OEM Plastic Engine Cover Electronic Plastic Shell Parts Moulding

PLASTIC INJECTION PART BASIC INFORMATIONProduct NameHigh Precision MoldProduct MaterialABS, PA, PA66+30GF, PBT, PC, POM, PP, PE, MA,PVC,TPE,TPU etcSurface RequirementSmooth, Polishing, Painting, SandBlasting, Electroplate, Silk-screen, Laser Etching, Anodizing,BrushingPlastic Part Resinthermoplastic

-

Interlocking Precast DIY Plastic Rubber Concrete Stepping Stone Mold

NameDIY Garden Path Maker MoldMould CavitySingle, Mult, FamilyShapeVarious, customizedMaterialPlasticColorBlack orCustomizedLife1500 timesCertificationCE,CCC,ISO,ROHSPrecision0.005mmThree Easy StepsUse the plastic concretePavement Mouldfor your yard,path and platform. All in an easy operation!How to

-

DIY Concrete Interlock Paver Pathway Molds for Garden Ornaments

NameDIY Garden Path Maker MoldMould CavitySingle, Mult, FamilyShapeVarious, customizedMaterialPlasticColorBlack orCustomizedLife1500 timesCertificationCE,CCC,ISO,ROHSPrecision0.005mmThree Easy StepsUse the plastic concretePavement Mouldfor your yard,path and platform. All in an easy operation!How to

-

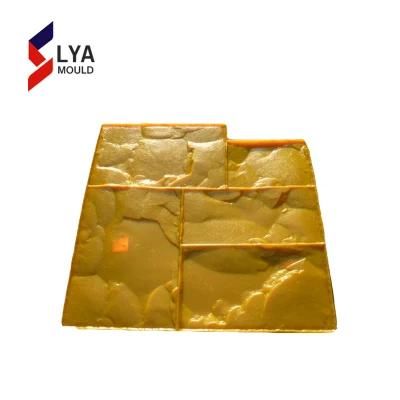

Wholesale OEM Accept Colorful Concrete Stamp Roller

Product Nameconcrete stamp mats concrete staming moldMaterialPU or rubberColorgreen, blue, yellow, brown, blackThickness20-25mmShapedifferent shapesLifepan20000-30000 timesUsagedriveway, pool deck, patio, walkway or walls.AdvantageflexibilityConcrete stamp matsadding a unique flair to your driveway,

-

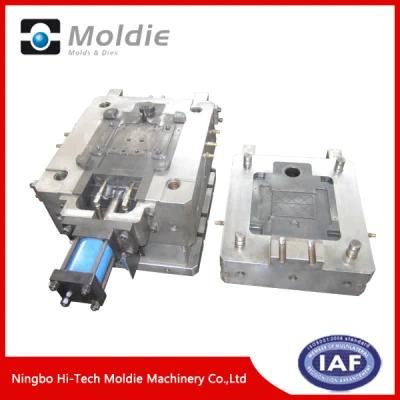

Plastic Injection PP Electrical Box Mould

Basic Info. Model NO. JZ Ru

-

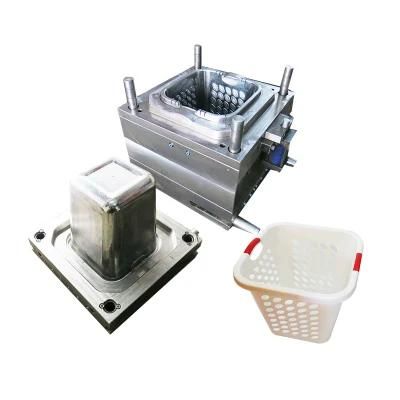

Guangdong Injection Moulding Maker Custom Plastic Laundry Basket Mould

BACK TO HOMEPAGE FOR MORE PRODUCTS!