Custom Elastosil Plastic Material Stamping Tooling Rubber Silicone Molds for Household ...

Qingdao Chuangyu Precision Machinery Co., Ltd.- Manufacturing Processes:Pressing Forming Mould

- Application:Home Use, Household Appliances, Car, Commodity, Electronic, Hardware

Base Info

- Transport Package:Cartons, Wooden Pallet or Customized

- Material:P20,718,H13,SKD11,2738...

- Logo Method:Laser Engraving, CNC Engraving Ect

- OEM/ODM:Yes

- Customized:Customized

- Warranty:1 Year

- Mould Life:500000-1000000 times

- Certification:CE

- Working Temperature:(-40℃-300℃)

- Surface Treatment:Polish

- Cavity:Multi-cavity

- Model NO.:CMP01

- Specification:up to design

- Trademark:Chuangyu

- Origin:China

- HS Code:8480419000

- Production Capacity:5000pieces,Month

Description

Basic Info.

Model NO. CMP01 Cavity Multi-cavity Surface Treatment Polish Working Temperature (-40℃-300℃) Certification CE Mould Life 500000-1000000 times Warranty 1 Year Customized Customized OEM/ODM Yes Logo Method Laser Engraving, CNC Engraving Ect Material P20/718/H13/SKD11/2738... Transport Package Cartons, Wooden Pallet or Customized Specification up to design Trademark Chuangyu Origin China HS Code 8480419000 Production Capacity 5000pieces/MonthProduct Description

Professional manufacturer for mold making and CNC machining with competitive price and good quality| Name | Customized Silicone Rubber Mold |

| Material | 100% Food Grade Silicone |

| Shipment | Sea shipment, air shipment, courier (door to door) shipment available. |

| Feature | Eco-friendly ,Funny,Durable,Unbreakable |

| Size | Customized |

| Color | Red, Blue, Green, Yellow, Orange or Any PMS Pantone or RAL Colors |

| Price | Factory price, large price favorably |

| Logo | Can be as your requirement |

| Temperature Range | -40ºC~230ºC |

| Certification | FDA,LFGB,SGS |

| Package | Opp bag inner packing,standard carton outer packing Or custom. |

| MOQ | 500pcs |

| Usage | Car, Household, Electrical, Machine... |

| Advantage | Safe to use in ovens, microwave ovens, dishwashers and freezers |

| After-sales Service>100% | |

| Non-stick, flexible and easy to handle |

Silicone rubber mold

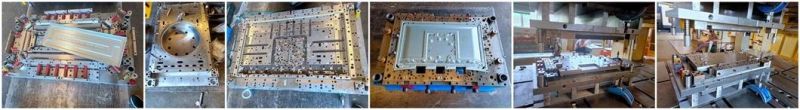

Plastic injection mold for automotive, medical, mask machine, household, electrical...

Stamping die for smal and big volume production...

CNC machining with different materials and surface treatment

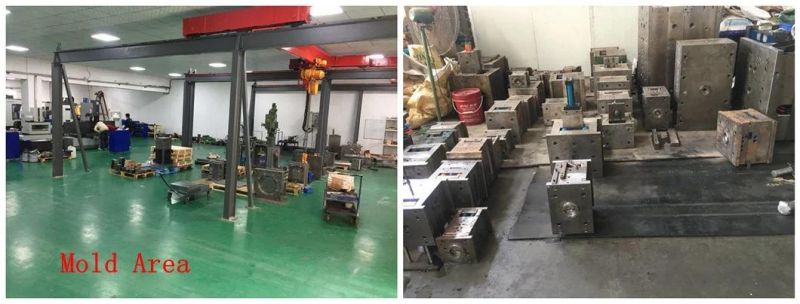

Factory:

To work with us, we do not just stop at taking your order and offer you molds and molding parts, we work together at every step all the way, in the design and function testing until the end of your project, we will review all of the possible potential issues and bring all of the suggestions to you. After the first sample parts coming out, our expert team will send you samples and review the parts, and we will re-sample for you from time to time until you have the perfect goods in surface, function, assembly, etc, until completely achieve your goal, you will find out we are the most responsible mold company that to support your business.

Our professional and exellent workers:

All of our workers have more than 5 years experience and received professional training from Japanese company as to ensure the products quality.

We could control the price and quality very well by our own equipments, such as Grinding machine, Milling machine, CNC center, Wire cutting, Injection machine ect.

Shipment:

We usually delivery the moulds and machinery parts by sea/DHL/FEDEX/TNT, according to the customers.

FAQ:

1.How can I get the quotation?

Please give us your drawing,quantity,weight and material of the product.

2.If you don't have the drawing,can you make drawing for me?

Yes,we are able to make the drawing of your sample duplicate the sample.

3.When can I get the sample and your main order time?

Sample time: 35-40 days after start to make mold.

Order time: 35-40 days, the accurate time depends on product.

4.What is your payment method?

T/T: 50% deposit,50%to be paid before shipment.

5.Which kind of file format you can read?

PDF, IGS, DWG, STEP, MAX

6.What is your surface treatment?

Including: powder coating, sand blasting, painting, polishing, acid pickling, anodizing, enamel, zinc plating, hot-dip galvanizing, electrophoresis, chrome plating.

7.What is your way of packing?

Normally we pack goods according to customers' requirements.