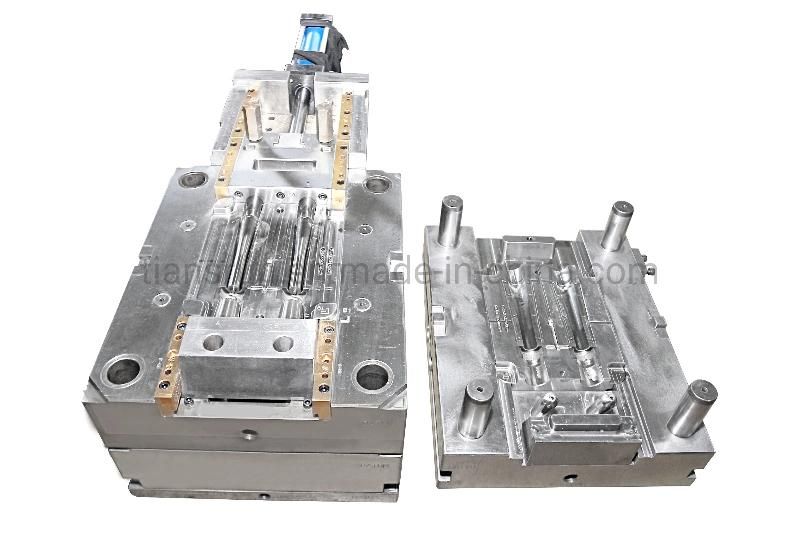

Plastic Car Auto Parts Injection Tooling

Ningbo Tiansrun Machinery Technology Co., Ltd.- Demoulding:Automatic

- Surface Treatment:Heat Treatment

- Material:H13, 45, 8407, SKD61

- Application:Car, Household Appliances, Home Use, Electronic, Hardware, Commodity

- Using Hardness:>HRC45

- Average Wall Thickness:>3mm

Base Info

- Trademark:TIANSRUN

- Transport Package:Wood Box and Pallet

- Lead Time:28 to 30 Days for Samples

- Condition:New

- Customized:Customized

- Certification:RoHs, ISO

- Mould Life:500,000-1,000,000 shots

- Model NO.:TS-01

- Origin:Ningbo, China

- Production Capacity:20 Sets,Month

Description

Basic Info.

Model NO. TS-01 Mould Life 500,000-1,000,000 shots Certification RoHs, ISO Customized Customized Condition New Lead Time 28 to 30 Days for Samples Transport Package Wood Box and Pallet Trademark TIANSRUN Origin Ningbo, China Production Capacity 20 Sets/MonthProduct Description

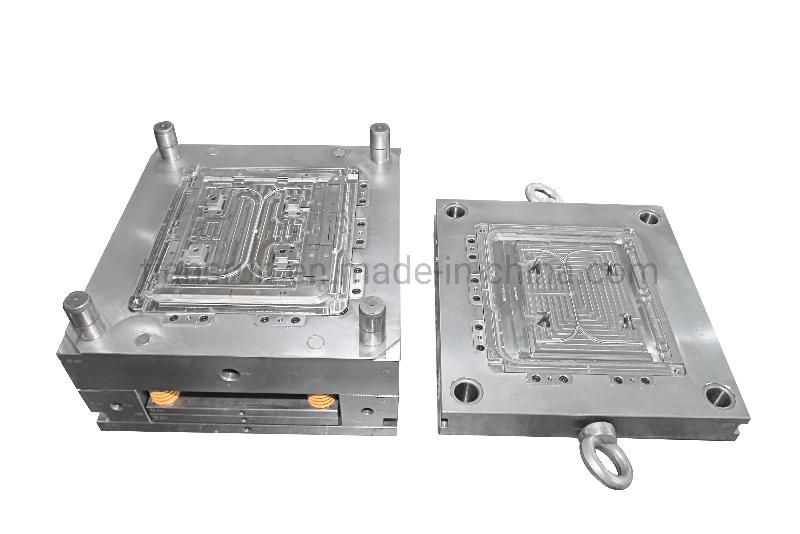

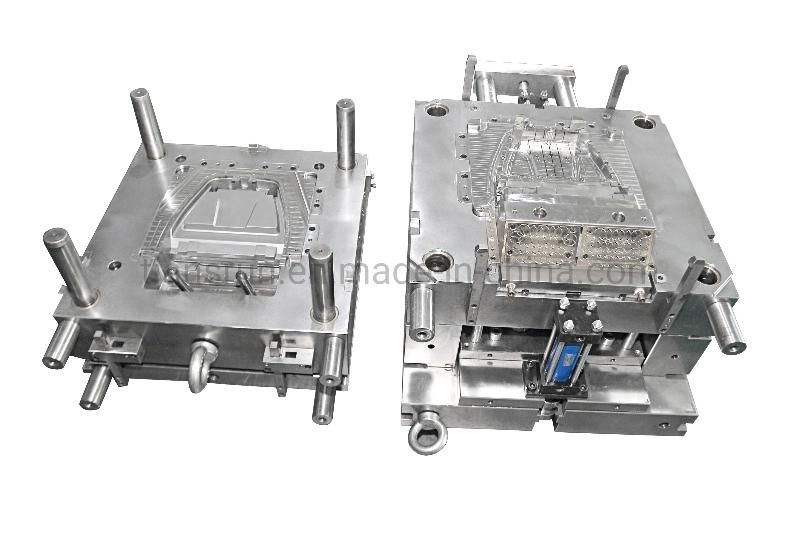

| Product name | Plastic Injection Mold |

| Mold Material | 718, 718H, S136, NAK80, P20, SKD61, H13, etc |

| Plastic Material | ABS, flame-resistant ABS,PC,PS,PP,PVC,TPR,TPU,TPE , HDPE,PMMA etc |

| Cavity Qty | Single Cavity, Multiple Cavity or Unit Cavity |

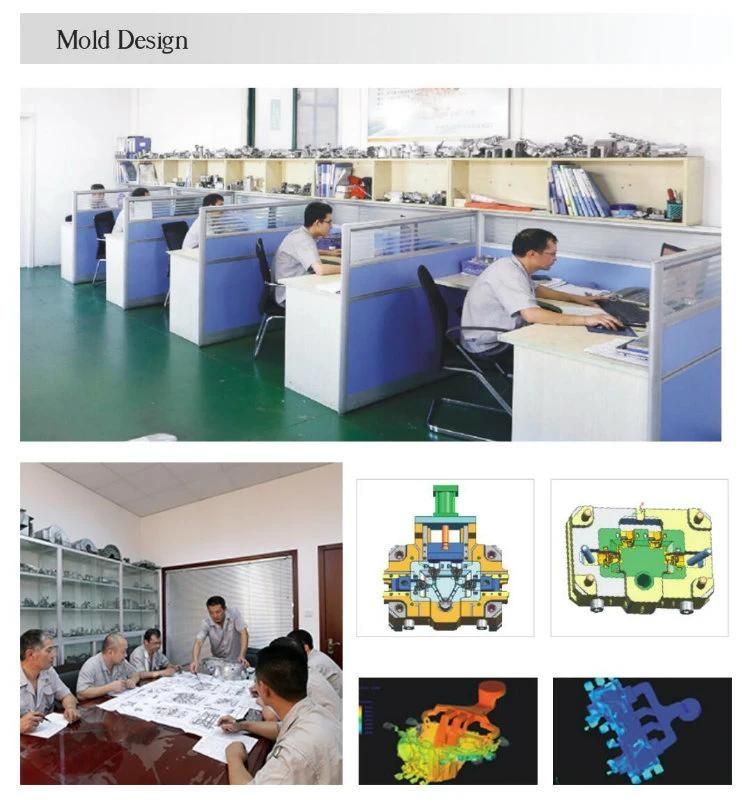

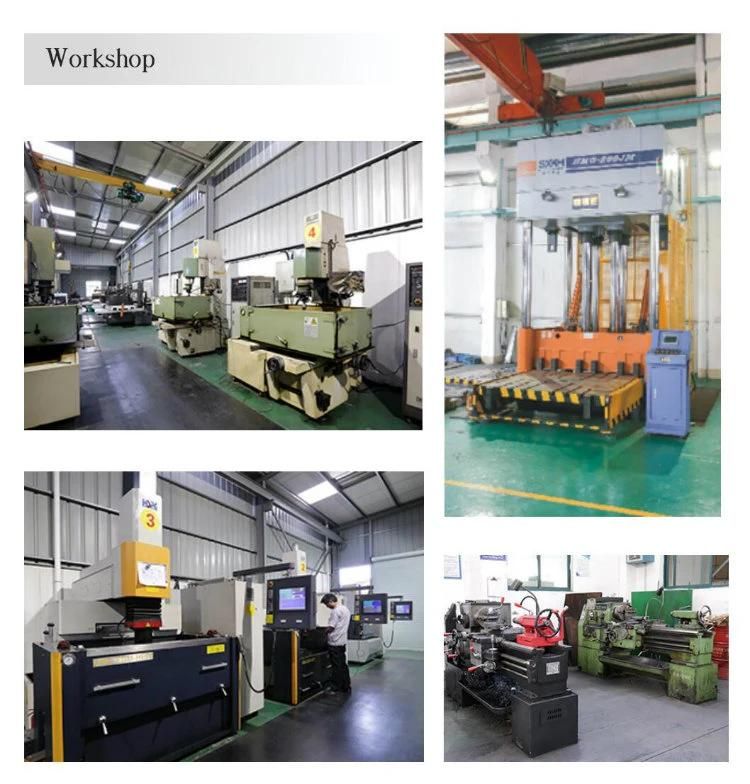

| Process | Adopts CNC, WEDM-LS, wire flame cutting machine, EDM, drill machine, polishing machines, Grinding machines, etc. |

| Treatment | Heat Treatment, Nitriding, Polish etc. |

| Design Software | AutoCAD, UG, Pro-E, Solidworks, etc. |

| Drawing File | IGS, STEP, SLD, X_T, DXF, DWG, SAT, STL |

| Lead Time | 28 to 30 days for samples, exact time depends on mold complexity |

| Mold Life | 100,000 to 1,000,000 depend on products |

| Special Requirement | According to your needs. |

FAQ

1. Q: Which kind of product can you do?

A: Mould manufacturing & die-casting for aluminum, zinc, copper, magnesium alloy parts.

Plastic parts, injection mould.

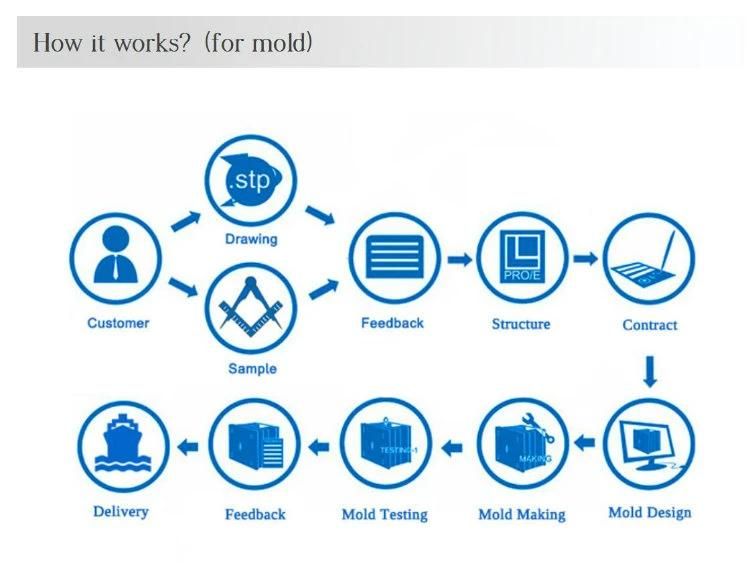

2. Q: Which kind information need for die casting mould making quotation?

A: 1) Sample photo with size or 2D/3D design

2) Cavity quantity

3) Runner type, cold or hot

4) Mould steel type H13, SKD-61, 8407, 3Cr2W8V, 4Cr5MoSiV, W400 and so on.

5) Die-casting machine parameter or plate size(tie rod distance)

3. Q: I have no 3D drawing, how should I start the new project?

A: You can supply us a sample, we will help to finish the 3D drawing design.

4. Q: Why choose us?

A: High quality, professional service, factory price, and timely delivery.