Injection Mold Plastic Mold Mold Making Tooling

Yuyao Xianghao Mold Technology Company Limited- Process Combination Type:Compound Die

- Plastic Material:TPE

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

- Application:Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Transport Package:Steel Box

- Plastic Injection Mould/Injection Mold:Plastic Mold,Plastic Injection Mould,

- Customized:Customized

- Certification:TS16949

- Standard:DME

- Installation:Mobile

- Design Software:UG

- Runner:Hot Runner

- Model NO.:Injection mould

- Trademark:injection mold

- Origin:China

- HS Code:8480410010

- Production Capacity:20 Sets,Month

Description

Basic Info.

Model NO. Injection mould Runner Hot Runner Design Software UG Installation Mobile Certification TS16949 Standard DME Customized Customized Plastic Injection Mould/Injection Mold Plastic Mold/Plastic Injection Mould/ Transport Package Steel Box Trademark injection mold Origin China HS Code 8480410010 Production Capacity 20 Sets/MonthProduct Description

plastic injection moulding in Plastic Mouldplastic injection moulding in Plastic Materials

injection plastic moulding making

plastic pallet injection moulding

plastic injection moulding pin

plastic injection moulding maker

plastic bucket injection moulding

plastic injection molding

plastic injection molding in Plastic Mould

plastic injection molding in Other Plastic Products

toy plastic injection molding

plastic chair injection molding

precision plastic injection molding

plastic injection molding part

plastic injection molding pen

plastic injection molding

plastic injection molding in Plastic Mould

plastic molding strip

toy plastic injection molding

plastic chair injection molding

custom plastic molding

plastic moulding in Plastic Mould

plastic moulding in Moulding

plastic moulding in Economic Mould

plastic injection moulding

picture frame plastic moulding

injection plastic moulding making

plastic frame moulding

plastic basket moulding

injection moulding in Plastic Mould

plastic injection moulding

injection plastic moulding making

injection moulding part

plastic pallet injection moulding

plastic injection molding

plastic injection molding in Plastic Mould

plastic injection molding in Other Plastic Products

injection molding parts

toy plastic injection molding

injection molding products

plastic chair injection molding

injection mould mold

injection mould

injection mould in Plastic Mould

injection moulding

plastic injection mould

injection moulded

precision plastic injection mould

bucket injection mould

injection mould maker

plastic moulding

plastic moulding in Plastic Mould

plastic moulding in Moulding

plastic moulding in Economic Mould

plastic injection mould

precision plastic mould

plastic chair mould

plastic box mould

Injection Mold

Specifications

Mold:

1. ISO/TS16949 Certificated

2. HASO. DME. LKM mould standard.

3. Design software: UG. PROE. CAD etc.

4. On-time delivery

1. Mold Material P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc...

2. Runner Cold runner. Hot runner: Yudo/DME/HASCO

3. Certificate ISOTS16949

4. Standard HASCO. DME, LKM

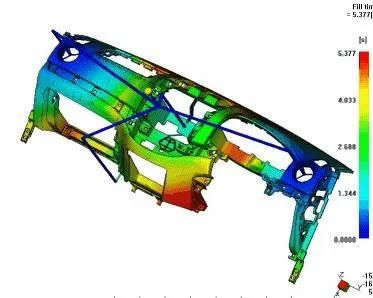

5. Specification drawings PRO/E, Auto CAD, Solidwork, CAXA UG, CAD/CAM/CAE.

6. Precision machining CNC, milling machine, drilling machine, numerical lathe, all types of lathe.

7. Surface finish process polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, mirror polishing.

8. Service OEM service available.

9. Lead time 15-25days

10. Advantage Good quality and strict delivery time.

| Parts Material | Plastic injection molding grade, such as PE, PVC ABS, PC, PP, POM, PA6( PA66, GF filled), PMMA, PET(PBT) |

| Cav.& Cor. Material | P20, H13,S136, NAK80, 718, 2738, 2316, SKD61 etc; |

| Mold Base | LKM, DME, HASCO or Customize according to customers' requirements; |

| Cavity quantity | 1*1, 1+1, 1*2, 1+1+1, etc. |

| Shot Runner | Cold or Hot Runner_ HASCO/DME/YUDO etc. |

| Mold lifetime | 100K to 1500k shots or according to customers quantity condition to decide it with saving cost for our customers. |

| Soft wares | CAD/CAM/CAE, UG, Pro/E, Powmill, Solid works etc. |

| Package | Wooden case packing or OEM packing |

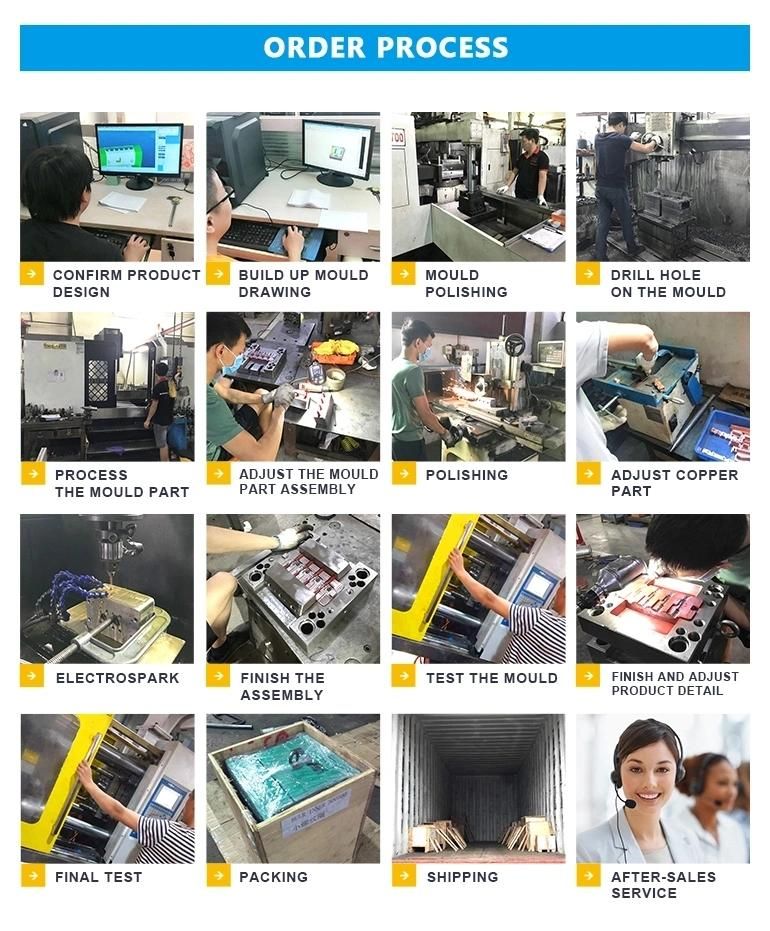

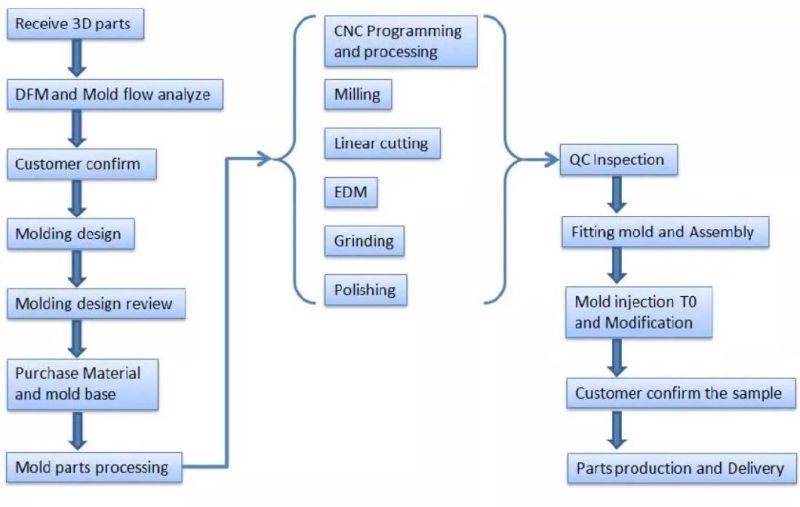

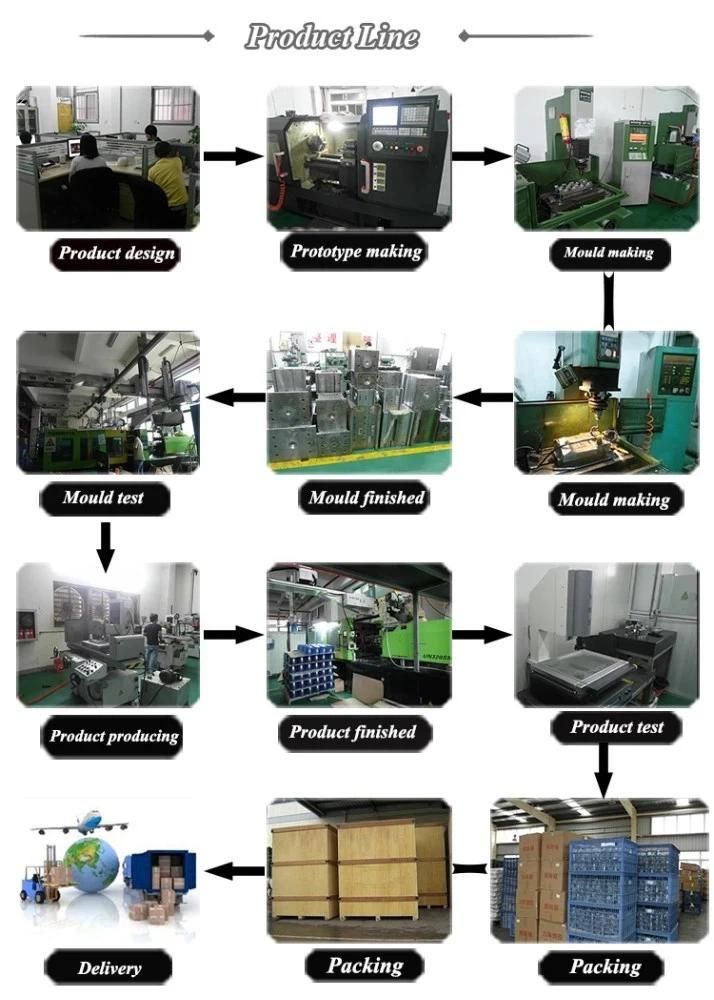

| Plastic Mold (Moulds) production process | |

| 1. OEM Service | OEM & ODM service, we can provide design service if needed |

| 2. Quotation | Including the price of moulds, moulds sizes, material for cores & cavities, weight of moulds, freights for moulds & parts (if needed), part cost, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | As per the customers' designs of parts, and suppliers accept the orders |

| 4. Confirmation | Provide moulds drawings to customers for confirmation, after that, order moulds base & material, start production |

| 5. Component | High speed chip makes the reflection more quickly |

| 6. sample shoot | provide the moulds test samples for confirmation, after that, mass production |

| 7. Delivery | deliver goods by air or by sea, as per the requirements of customers |

| 8. Package | Wooden case for moulds, cartons for parts |