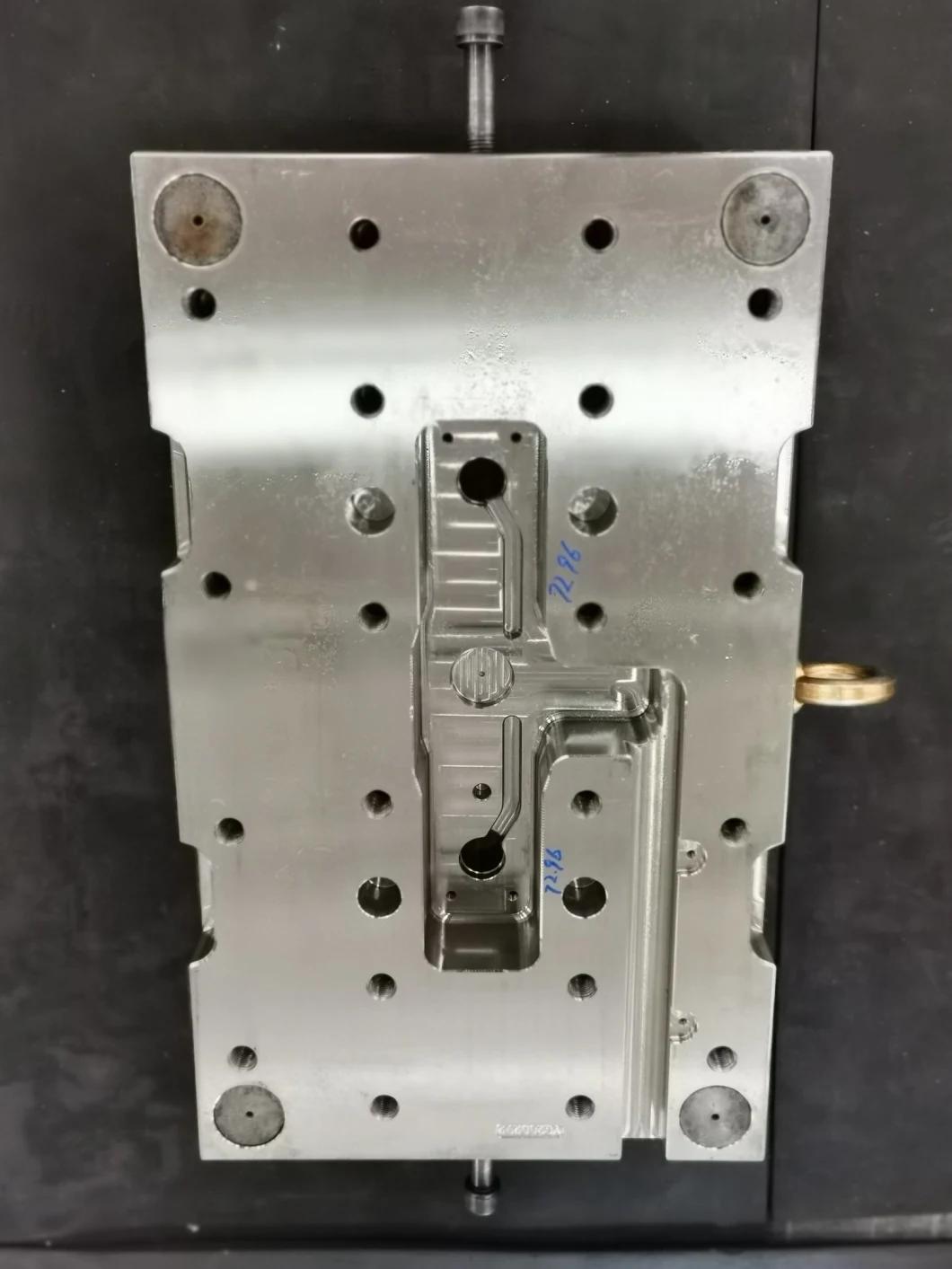

Plastic Mould, Plastic Pallet for Warehouse Store, Food Store

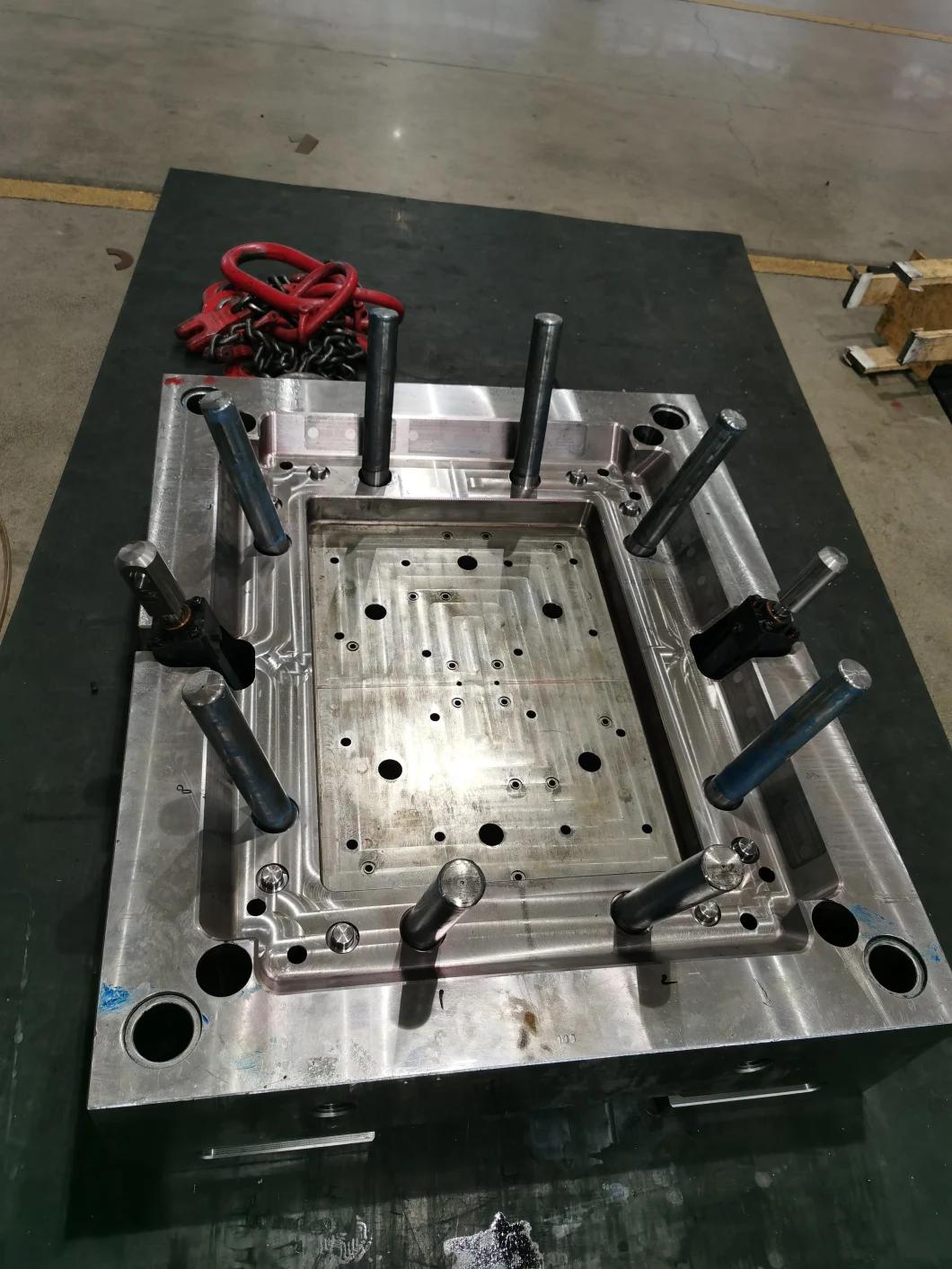

Zhejiang Right Precision Mould Co., Ltd.- Process Combination Type:Compound Die

- Plastic Material:PP, Pet, ABS, etc

- Mould Cavity:Multi Cavity

- Surface Finish Process:Mirror Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Commodity, Home Use, Food Store

Base Info

- Quality:Good Quality

- Precision:High Precision

- Hardness:High Hardness

- Customized:Customized

- Standard:Hasco, Dme, Misumi

- Installation:Fixed

- Design Software:Ug, CAD, Moldflow

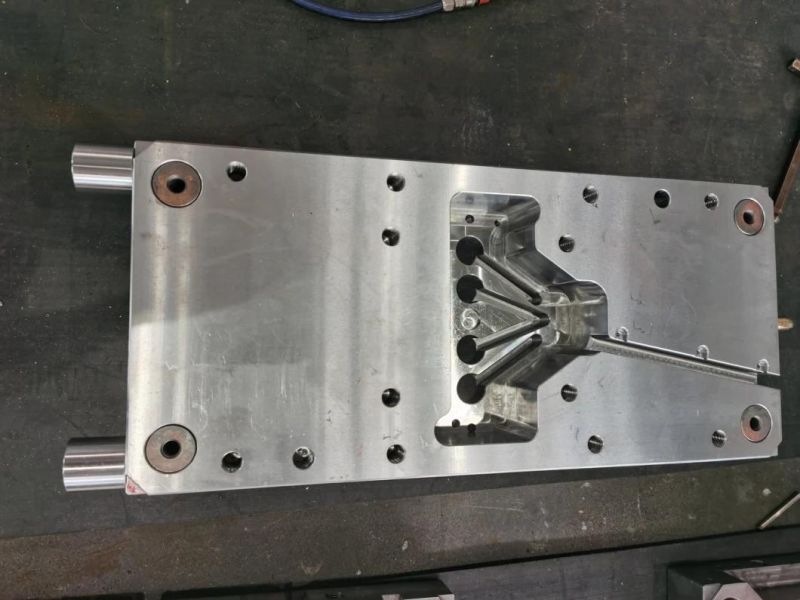

- Runner:Hot Runner

- Transport Package:Wooden Case

- Origin:Zhejiang, China

- HS Code:8480719090

- Production Capacity:600sets,Annual

Description

Basic Info.

Runner Hot Runner Design Software Ug, CAD, Moldflow Installation Fixed Standard Hasco, Dme, Misumi Customized Customized Hardness High Hardness Precision High Precision Quality Good Quality Transport Package Wooden Case Origin Zhejiang, China HS Code 8480719090 Production Capacity 600sets/AnnualProduct Description

Mould details:1. Design 3D drawing for customers' confirmation according to their 2D drawing or sample when placing to order.

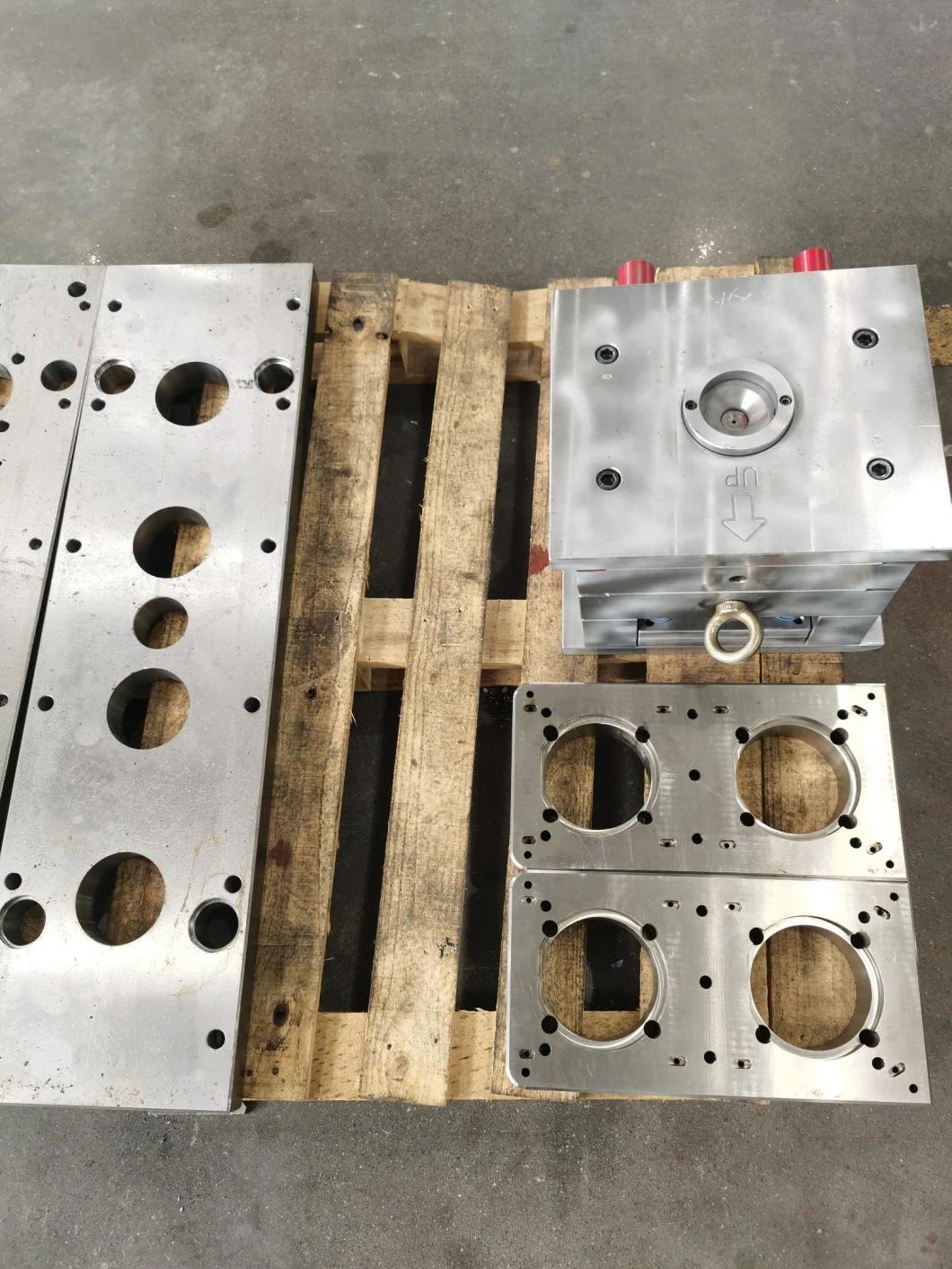

2. Mould Matieral: Different grade: P20, S136, 2316, H13, etc.

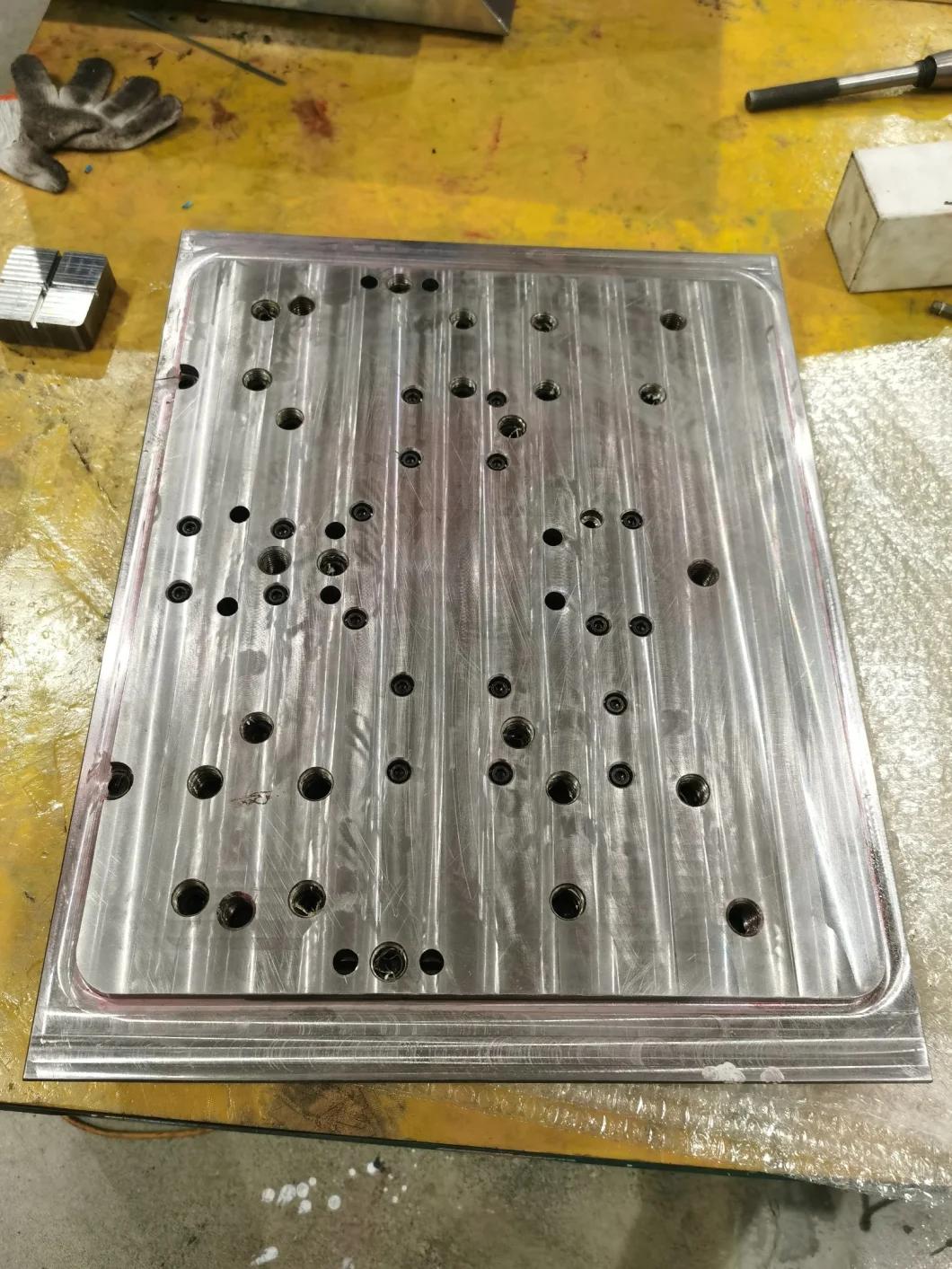

3. Surface treatment: mirror polish, polish, texture

4. Independent temperature control & heating system Which boasts an even heating temperature and keeps product with reliable and stable quality.

5. Mould life: more than 1 million shots

All inserts can be interchangable.

6. Product matieral: ABS, PC, PE, PMMA, POM, PP, PBT, PSU, PVC, PA6, PA66+GF,ect

7. Quick deliver time: 25-60 days

| Name | food packaging plastic injection mould |

| Plastic material | PP, PET, etc |

| Steel of Cavity & Core | 2316 |

| Steel of Mouldbase | 45 steel |

| Nos of Cavity | multi-cavity, depends |

| Hardness of Cavity & Core | 42-45HRC |

| Hardness of Wear Parts | 42-48HRC |

| Core pulling system | hydraulic cylinder |

| Mould Accessories | HASCO Standard |

| Cooling system | In core baffle cooling and in cavity plate chain drilling type cooling |

| Surface finish | mirror polishing |

| Molding Life | 1,000, 000shots |

| Runner | hotrunner |

| Delivery time | 35-50 work days |

| Packing | wooden case |

Please allow me to introduce something about our factory as belows, thank you in advance!

We are a professional plastic precision mould maker and manufacturing factory from China, customized and personalized plastic injection mould according to our clients requirements, mainly for PVC pipe fittings , auto and motorcycle plastic parts, daily necessities, preform, thin wall food packing container, made and developed by our advanced equipment machine, such as Makino 3axis, 4axis, 5axis CNC machine, Mitsubishi EDM, WEDM, Mazak CNC machine, and so on, other molds also welcome to negotiate to design and manufacture.

We also could make the mould parts & components processing tooling machinery with our advanced equipment machine.

Our products are suitable for injection mould machines of all major brands on the market. Successfully provide customers with a perfect one-stop complete solution from production design-mold design & programming -laying-off -machine CNC processing-assembling for injection moulding, including mould modificaiton, mould parts and components.

Ok, that is it, if you have any such mould inquiry or developed for plastic products, please feel free to contact with me ! Thank you in advance!

Best regards

StanleyZhejiang Right Precision Mould Co.,LtdAdd.: No. 3 Shengda Road, Zeguo Town, Wenling city, Zhejiang Province, China