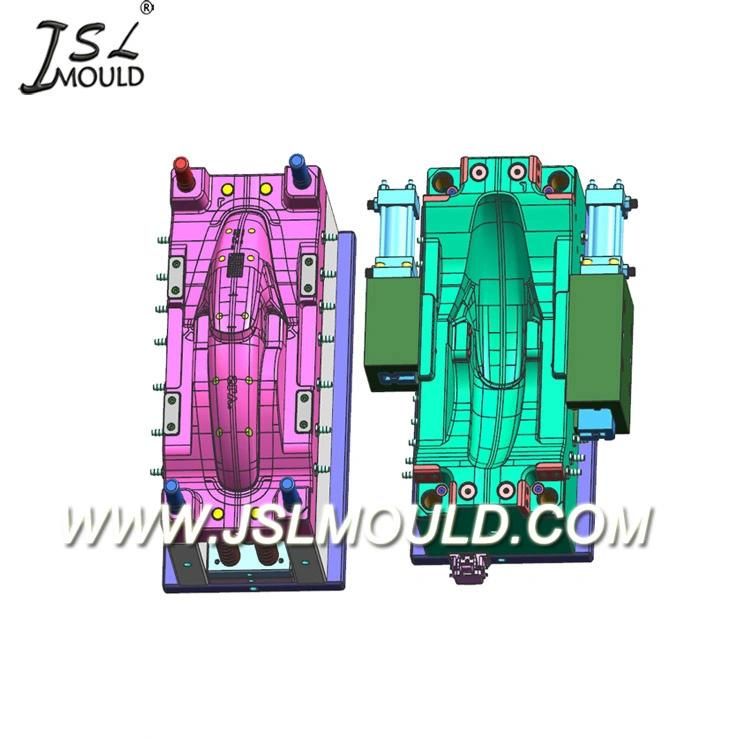

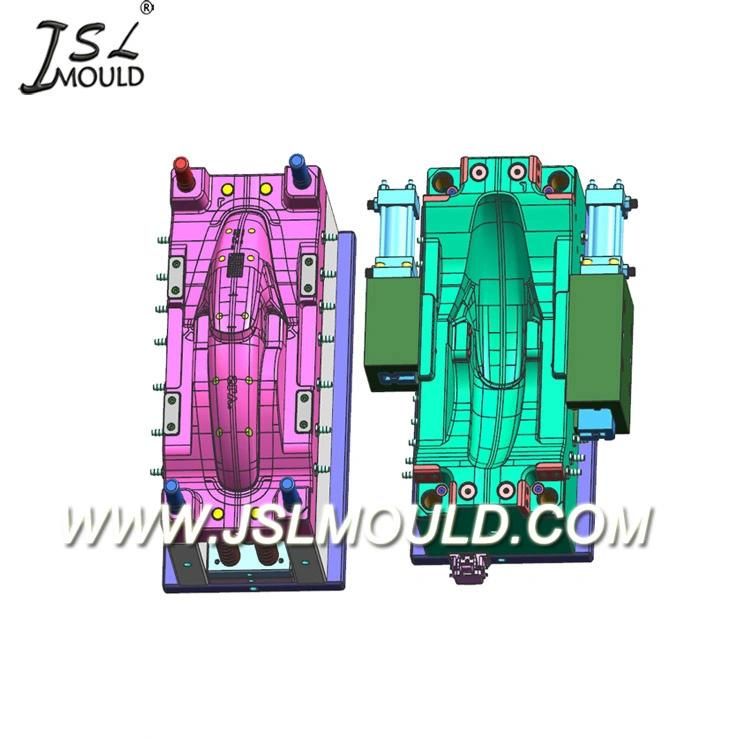

Customized Plastic Motorcycle Scooter Mudguard Mould

Taizhou City Huangyan Beiwei Mould Industry Co., Ltd.- Plastic Material:ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Polish or Texture

- Shaping Mode:Injection Mould

- Process Combination Type:Single-Process Mode

- Application:Car

Base Info

- Mould Report:7-10days Per Time

- Mould Design:7days

- Heat Treatment:Nitriding, etc

- Mould Operating Mode:Automatically by CNC

- Mould Cooling System:by Experienced Designer

- Machine Equipment:CNC,EDM,Wire Cutting Machine,Drilling,Grinding

- Mould Base:S50c,C45

- Mould Quality Control:Professional QC in House Machine

- Customized:Customized

- Standard:Dme,Lkm,Hasco

- Certification:ISO

- Installation:Fixed

- Design Software:Ug,PRO-E,Solidwork Ect

- Runner:Hot ,Cold Runner

- Model NO.:J1808161

- T1 Sample:60days

- Aftersale:Yes,1 Year

- Transport Package:Wooden Crate

- Specification:AS REQUIREMENT

- Trademark:JSLMOULD

- Origin:Taizhou, China

- HS Code:8480719090

- Production Capacity:500 Sets Molds,Year

Description

Our Advantage1. High quality 2. Reasonable price 3. On time delivery 4. Good After-sale service 5. Strict quality control 6. All the mould are automotic. Offer you In-time response on letters, telephone calls or fax In-time supply the quotation and mould designs In-time communication on the technical points In-time sending pictures for the mould machining progress and mould finishing schedule In-time mould test and sample delivery In-time mould delivery For more information please contact us.

Plastic mudguard mould

Provide mould core & cavity steel certificate

Provide mould trial video and good after-service

1. Long life

2. Short delivery time

3. With best machining

4. Good after-service

JSL Mould Quality Control

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking(Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- checking each part of mould's size after machining, according to 2D drawing

- mould testing(check mould running condition)

3. Check with customer's requirement again before mould shipping

Plastic mudguard mould

Provide mould core & cavity steel certificate

Provide mould trial video and good after-service

1. Long life

2. Short delivery time

3. With best machining

4. Good after-service

JSL Mould Quality Control

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking(Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- checking each part of mould's size after machining, according to 2D drawing

- mould testing(check mould running condition)

3. Check with customer's requirement again before mould shipping