Customized Precision Plastic Injection Mould for Auto Parts Molding

Qingdao Chuangyu Precision Machinery Co., Ltd.- Surface Finish Process:Anodizing

- Mould Cavity:Custom Cavity

Base Info

- Transport Package:with PE Plastic Packed Then Into The Wooden Box

- OEM:Yes

- ODM:Yes

- Material:Stainless Steel,Metal Ect

- Polish:High Polish

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Cold Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:HDPE

- Model NO.:CM01

- Specification:up to design

- Trademark:Chuangyu

- Origin:China

- HS Code:8480419000

- Production Capacity:20pieces,Month

Description

Basic Info.

Model NO. CM01 Plastic Material HDPE Process Combination Type Single-Process Mode Application Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware Runner Cold Runner Design Software Pro-E Installation Fixed Certification CE, ISO Standard HASCO Customized Customized Material Stainless Steel/Metal Ect Polish High Polish ODM Yes OEM Yes Transport Package with PE Plastic Packed Then Into The Wooden Box Specification up to design Trademark Chuangyu Origin China HS Code 8480419000 Production Capacity 20pieces/MonthProduct Description

Professional OEM/ODM Plastic Injection Mould/Stamping Die/Rubber Mold for Car Parts| Products Name | Plastic Injection Mould |

| Design | Client 2D, 3D design drawing, or ODM by us |

| Mold base | LKM, HASCO, DME...etc |

| Mold Material | Steel, H13, SKD11, P20, 718, 2738, NAK80, S136, …etc |

| Mould Cavity | Singe or multi cavity |

| Tolerance | +/-0.001mm |

| Sprue gate | Hot/cold runner, pin-point gate, etc |

| Runner | Hot runner, Cold runner, Pin-point gate, Submarine gate, etc |

| Hot Runner Brand | Yudo/ Mastip/ HASCO/ DME/ MOLD-MASTER…etc |

| Plastic Material | ABS, PC, PP, PE, PA, PS, +GF, POM, PMMA, …etc |

| Mold Life | 100K-500K shots shots as per customers' requirement |

| Surface treatment | Polishing, Sand Blasting, Heat Treatment |

| Package | Standard or as you request |

| Inspection | As customers' requirements |

| Delivery | Air cargo, Sea shipping, or as you request |

| Lead time | 25-45 workdays based on the different products |

| OEM/ODM | Acceptable |

| Certificate | ISO9001: 2015, SGS, BV, TS16949, CE, FCC, RoHS |

Factory:

We are a professional manufacturer specializing in plastic injection molds and molding with rich experience. We can make molds and plastic parts in variety of industry, such as electronics, automotive parts, medical parts, precise parts...ect.

We pay very high attention to the quality, bcz of that we gain many good feedbacks from our clients and orders, our goal is to work long time cooperation with our clients, not only one or two times, only good quality with best price could last it long.

Our main Products: plastic injection, stamping die, rubber mold, extrusion mold... for car, medical, household, machine, window, door...ect

Our service:

1: Prompt response (respond within 1~10 hours);

2: Complete quality control system for every stage of production;

3: Competitive price with good quality;

4: Advanced project tracking system, delivery on time(4~7 weeks);

5: Rich Experiences in exporting molds to overseas markets;

Metal Machinery Parts:

Except mold making, we also make machinery parts for Household Appliances/ Car/ Commpdity/ Home Use/ Electronic/ Offical Equipment/ Medical Apparatus ect.

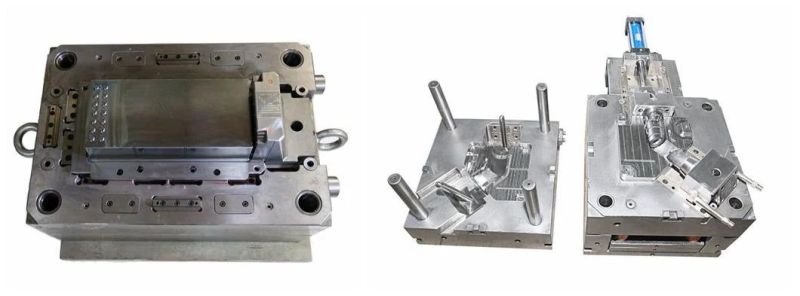

Mould Display:

We are a very strong and professional factory, we made many moulds for many big companies and work with them for so many years, such as Haier, we have our own design team in their company as to design for them special, we pay high attention to the mold's precision as to meet our client's requirement.We also have the professional QC team to check the mold and machinery parts before shipment as to avoid any mistake.

Shipment:

We usually delivery the moulds and machinery parts by sea/DHL/FEDEX/TNT, according to the customers.

FAQ:

FAQ:1. Q: what is the processing for the quote ?

A: We can quote from your 3d formats like IGS,STP,PARASOLID etc and 2D drawings as well; quote the price to clients after got the 2d or 3d drawings within 2 hours;

2. Q: How is the next ?

A: We will send the cost to you and get your confirmations for the quote;

3. Q: what is the software will you use for the proceeding ?

A: We make the 3D programm with Pro-Engineer, UGS, SOLIDWORKS, MASTERCAM etc ;

4. Q: what is the type of machines for manufacturing ?

A: Manufactured from CNC Machining, Laser cutting , stamping ,injection as well as the parts files different ;

5. Q: Do you do the surface treatments please ?

A: Yes, sure. we do the surface treatments, for instance: chromated, powder coating, Anodizing, laser etching as well as painting ;

6. Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping;

If you have any doubts, please contact me freely.