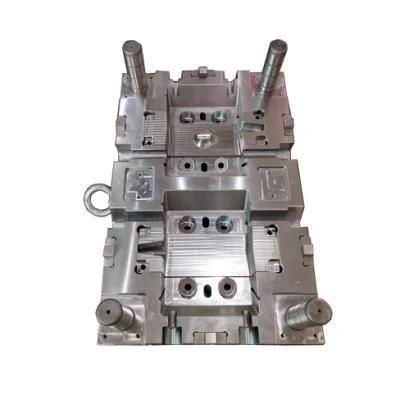

Custom Multi Cavity Injection Mould for Multi Color Moulded Parts

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Furniture, Electronic, Hardware, Household Appliances, Commodity, Home Use

- Process Combination Type:Single-Process Mode

- Plastic Material:PE

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Process:CNC Turning, Drilling, Milling, Punching.....

- Plastic Color:Nature, White, Black, Red, Yellow, etc

- Surface Treatment:Polishing,Smooth, Texture,Frosted, Printing, etc

- Normal Plastic:ABS, PP, PE, EVA, PS

- Mold Life:300, 000~1, 000, 000shots

- Mold Standard Components:Hasco, Misumi, Meusburger, Dme, etc

- Product Name:Plastic Injection Molds

- After-sales Service:Any Question Please Feel Free to Contact Us.

- Standard:DME

- Customized:Customized

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Runner:Cold Runner

- Model NO.:HW-1031

- Lead Time:5-30 Working Days After Receiving Deposit or L.C

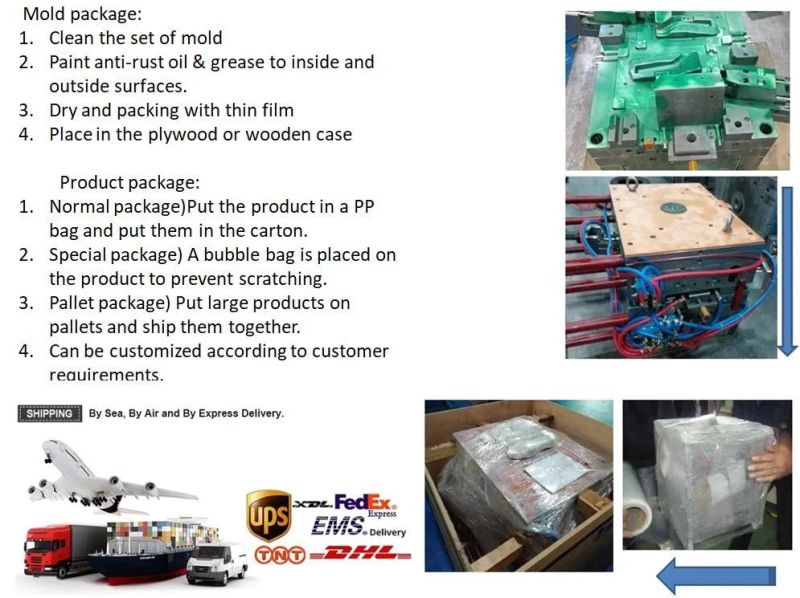

- Transport Package:Wooden Cases,Air,Sea

- Specification:Custom

- Trademark:HOWE or Custom

- Origin:China

- HS Code:8522901000

- Production Capacity:40sets,Month

Description

Overview

Product DescriptionCompany Profile Quality Control

Quality Control

FAQ about Plastic Injection Mold

Q1: Are you manufacturer or trading company ?

A1: We are the manufacturer of Injection moulding parts, our price is more competitive.

Q2: Do you support OEM/ODM service?

A2: Yes, we have a large experienced R&D team, we can offer one-stop service,so welcome to place OEM/ODM orders to us.

Q3: How long is the lead-time for a plastic injection mold?

A3: It all depends on the mold's size and complexity.Normally, the lead time is 25-45 working days.If the plastic moulds are very simple and in small size, we can work out within 15 days.

Q4: What kind of plastic materials you usually use?

A4: We are specialized in producing plastic products with the following materials:

PP,ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

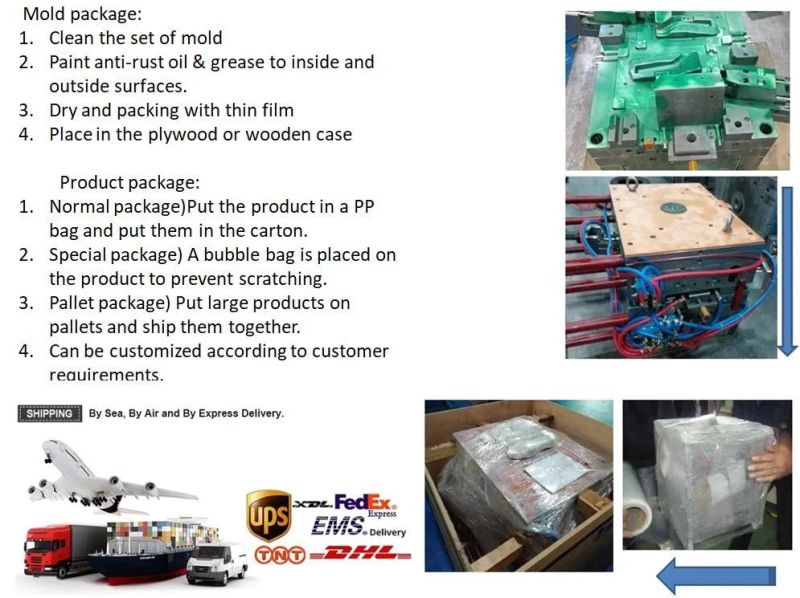

Q5: How do you pack the plastic molded parts?

A5: We pack the plastic molded parts by thick-wall export cartons.If the finish surface of plastic molded parts requires safe protection to avoid scratches, we will use bubble plastic bag to pack the parts.

Q6: How does your factory do regarding quality control?

A6: Secure production under strict quality control system; Quality is priority. 100% products tested. CE/ ROHS FCC/ Certification are available if required.

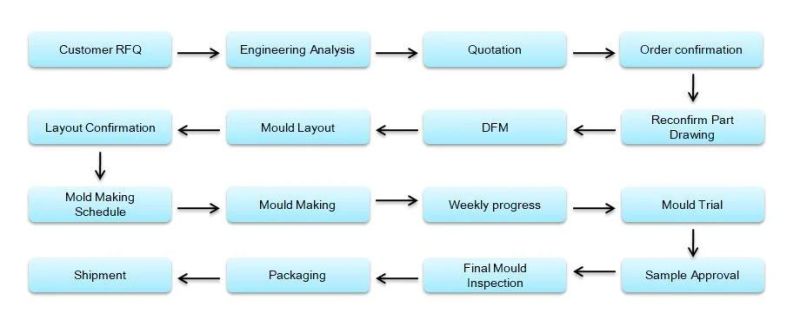

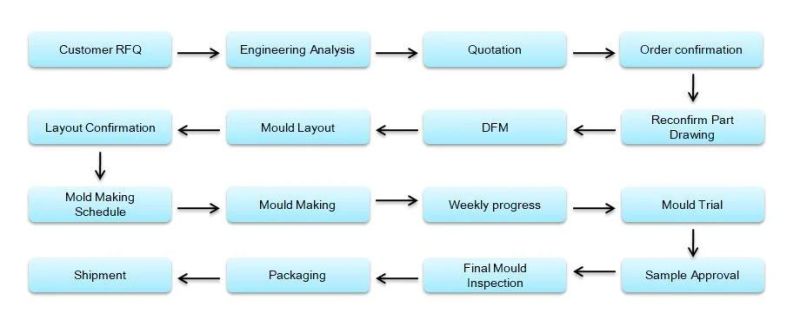

Howe Precision Mold Co. Mould Trade Process

Quality Control

Quality ControlWork Shop

Customer Visiting

Advantage

Packaging & Shipping

FAQ about Plastic Injection Mold

Q1: Are you manufacturer or trading company ?

A1: We are the manufacturer of Injection moulding parts, our price is more competitive.

Q2: Do you support OEM/ODM service?

A2: Yes, we have a large experienced R&D team, we can offer one-stop service,so welcome to place OEM/ODM orders to us.

Q3: How long is the lead-time for a plastic injection mold?

A3: It all depends on the mold's size and complexity.Normally, the lead time is 25-45 working days.If the plastic moulds are very simple and in small size, we can work out within 15 days.

Q4: What kind of plastic materials you usually use?

A4: We are specialized in producing plastic products with the following materials:

PP,ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

Q5: How do you pack the plastic molded parts?

A5: We pack the plastic molded parts by thick-wall export cartons.If the finish surface of plastic molded parts requires safe protection to avoid scratches, we will use bubble plastic bag to pack the parts.

Q6: How does your factory do regarding quality control?

A6: Secure production under strict quality control system; Quality is priority. 100% products tested. CE/ ROHS FCC/ Certification are available if required.