-

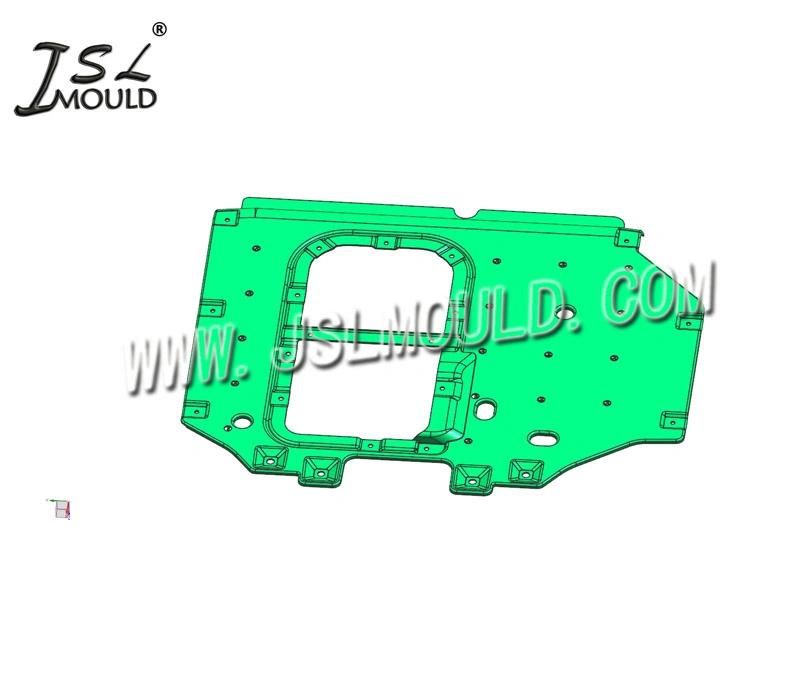

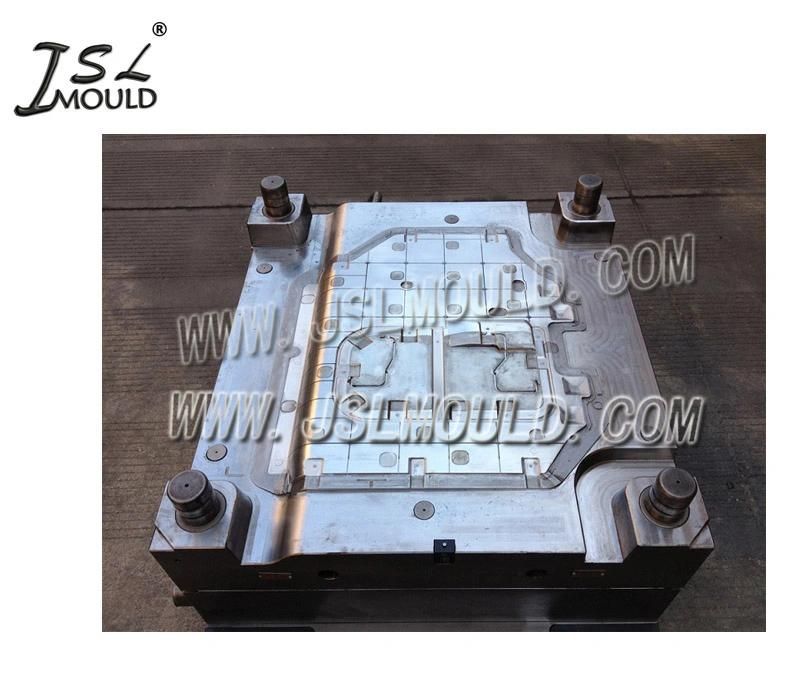

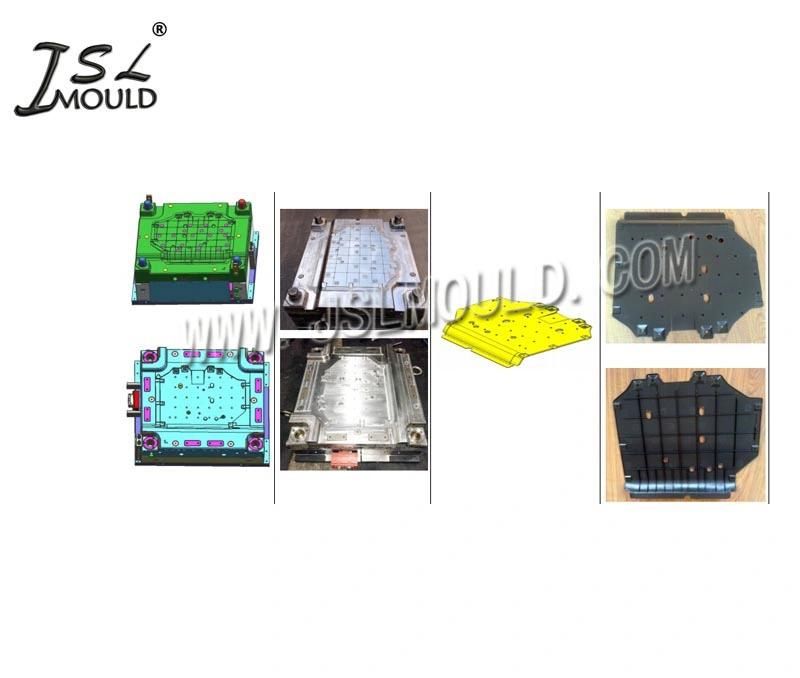

High Quality Custom Plastic Car Engine Splash Shield Mold

Our Advantage1.High quality2.Reasonable price3.On time delivery4.Good After-sale service5.Strict quality control6.All the mould are automotic.Offer youIn-time response on letters, telephone calls or faxIn-time supply the quotation and mould designsIn-time communication on the technical pointsIn-time

-

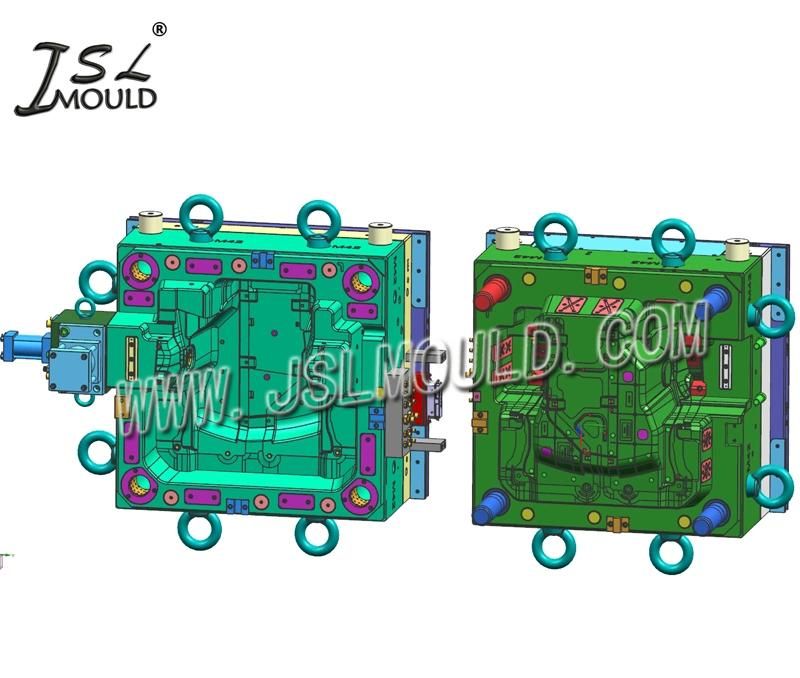

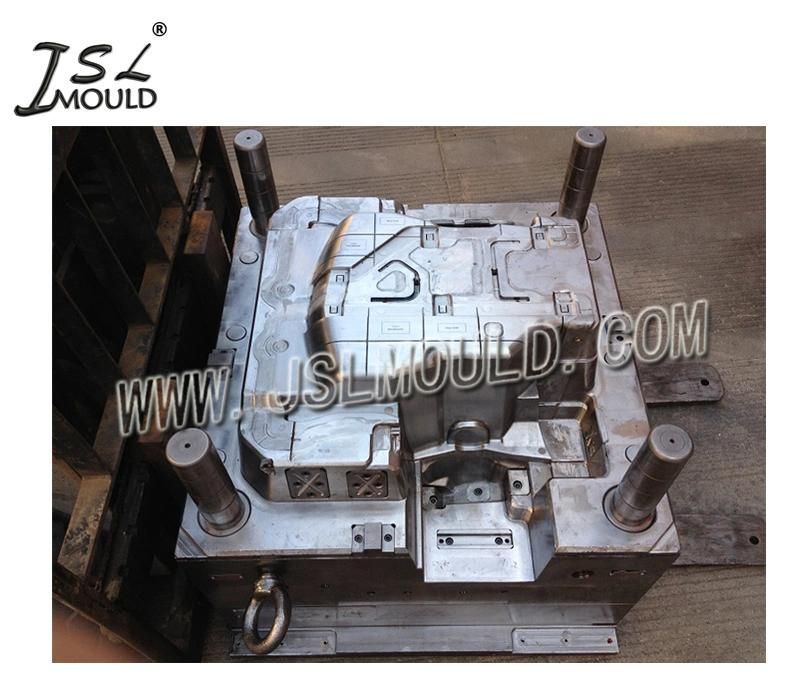

Experienced Making Premium Injection Auto Tail Light Lens Mould

Our Advantage1.High quality2.Reasonable price3.On time delivery4.Good After-sale service5.Strict quality control6.All the mould are automotic.Offer youIn-time response on letters, telephone calls or faxIn-time supply the quotation and mould designsIn-time communication on the technical pointsIn-time

-

High Quality Plastic Home Use Storage Box Injection Mould Maker

production namehousehold storage box mouldplastic materialPPmould material2344mould life5 millionrunnerhotejection methodstripper plate with airdemoulding methodfull automatic and by robot*Excellent cooling system*Uniform wall thickness,the product is not deformed,a high modulus*Highly polished surf

-

Long Working Life Wires Tungsten Carbide Mold Drawing Die

S11-860.3-1.00.3-0.614°1080.70.614°13100.4-2.80.3-1.616°15130.5-3.00.3-1.416°16140.4-3.80.3-1.816°20171.2-4.72.0-2.618°21171.8-5.71.2-3.018°22181.7-6.41.2-3.018°Type WTypeDHdhα°W102-d960.4-1.30.4-0.712°W103-d1280.2-2.70.5-1.414°W104-d15100.5-5.00.5-2

-

Plastic Thin Wall Lunch Box Mould Food Container Injection Molding

production nameplastic food container mouldplastic materialPPmould material2344mould life5 millionrunnerhotejection methodstripper plate with airdemoulding methodfull automatic and by robot*Excellent cooling system*Uniform wall thickness,the product is not deformed,a high modulus*Highly polished sur

-

Custom Plastic Fabrication Manufacturer Hard Plastic Injection Molded Case

Processing MethodPlastic Injection, Stamping, Welding, CNC Milling, CNC Turning, Turning-Milling Machining, Micro Machining.MaterialPC, POM, PTFE, Stainless Steel, Alloy Steel, Carbon Steel, Free-cutting Steel, Brass, Copper, AluminumFinish TreatmentPolishing, Sand Blasting, Anodizing, Zinc Plating,

-

Premium Motorcycle Full Face Helmet Visor Mould

Product NamePremium Motorcycle full face helmet visor mouldProduct materialPCCore&Cavity Steels136 ECTSteel hardness:HRC48-52Mould StandardDME/LKM/HASCOCavity NumberONE Or multiInjection SystemSide gateEjector SystemEjector bladeCycle Time30sTooling lead time60 daysMould life2,000,000timesQualit

-

Plastic Full Face Motorcycle Helmet Mould

Product NamePlastic full face motorcycle helmet mouldProduct materialABSCore&Cavity SteelP20/718/2738 ECTSteel hardness:HRC35-38Mould StandardDME/LKM/HASCOCavity NumberONEInjection SystemSide gateEjector SystemEjector blockCycle Time50sTooling lead time60 daysMould life500000timesQuality assuran