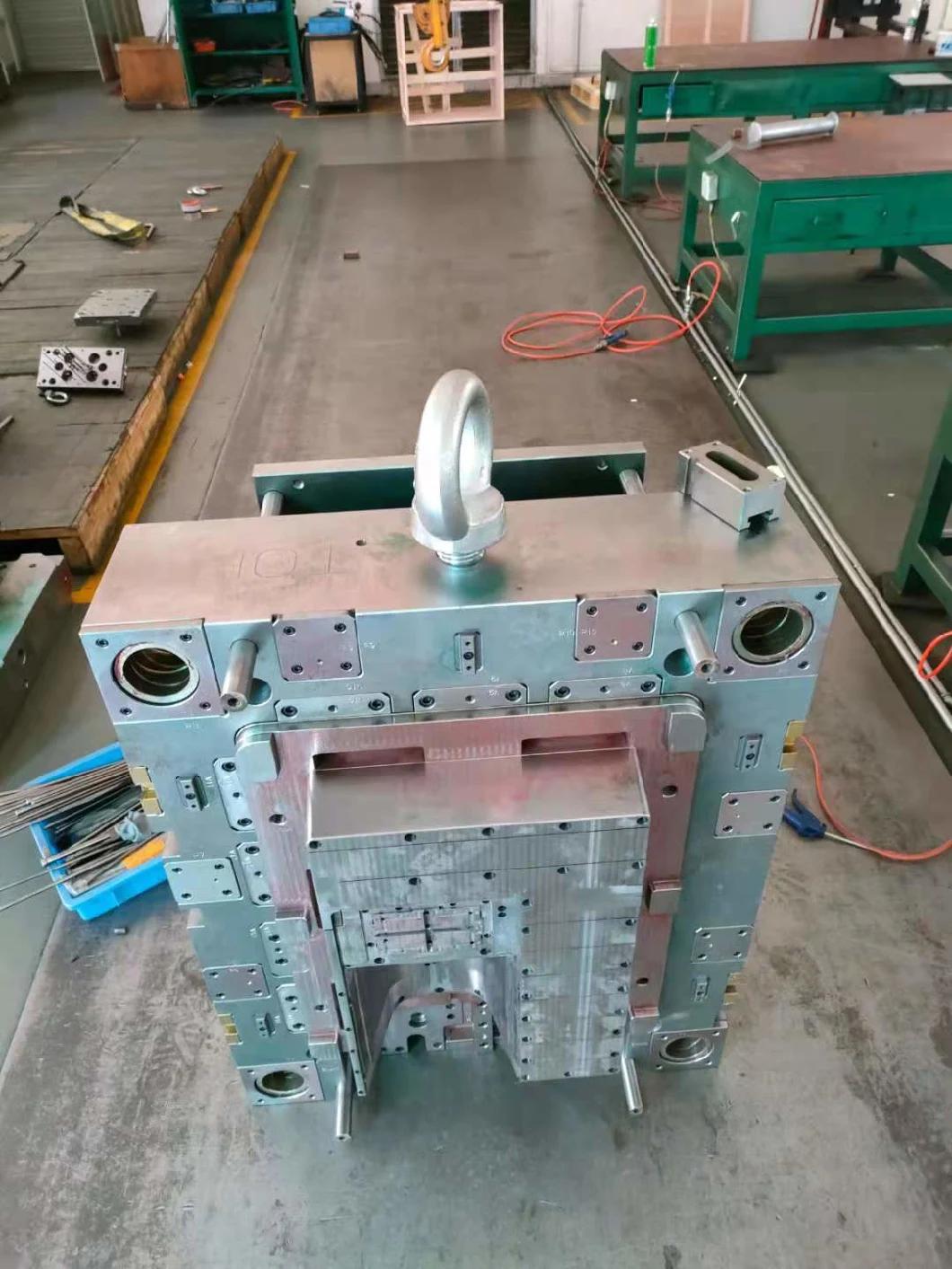

Customized Design Plastic Injection Molding for Automotive Spare Parts

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Advantages:11 Years Experience

- Gate Type:Side Gate, Sub Gate, Pin Point Gate, Edge Gate etc

- Injection Machine Tonnage:50t-3600t

- Process:Grinding, Milling, Drilling, etc.

- Lead Time:15-45 Working Days

- Mould Life:300K~500K Shots

- Quote:According to Samples, Drawing and Specific Require

- Cavity:Will Basis on Qty Plan and Customer′s Requirements

- Product Name:Multi Cavity Cold Runner Injection Mould

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Cold Runner

- Model NO.:HW-1002

- Mold Base:Lkm or According to Customer Requirements

- Transport Package:Safety Package

- Specification:According to your drawing

- Trademark:Customized

- Origin:Guangdong, China

- HS Code:8480719090

- Production Capacity:40sets,Month

Description

BACK TO HOMEPAGE FOR MORE PRODUCTS!