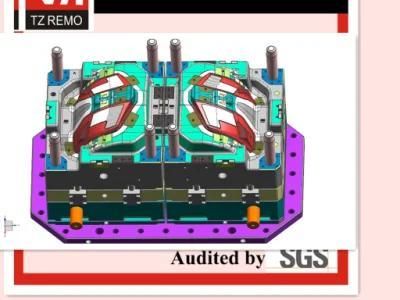

The Light for Auto Mould

Taizhou Remo Plastic Mould Co., Ltd.- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Surface Finish Process:Heat Treatment

- Shaping Mode:Injection Mould

- Process Combination Type:Progressive Die

- Application:Auto Mould

Base Info

- Sample Time:45-60 Days

- Mould Standard:Lkm, Hasco

- Mould Life:1 Million Shots

- Injection Machine:Haitian

- Machining:CNC, EDM, Deep Hole Drilling

- Mould Material:P20 , 718 , 2738

- Deliery:by Sea or Air

- Polish:Mirrior Polish

- Cavity Numbers:Single , Double

- Name:Auto Car Mould

- Customized:Customized

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:RM00945

- Transport Package:Wooden Case

- Specification:International

- Trademark:REMO

- Origin:Taizhou China

- HS Code:8480719090

- Production Capacity:100 Sets,Month

Description

Basic Info.

Model NO. RM00945 Runner Hot Runner Design Software UG Installation Fixed Customized Customized Name Auto Car Mould Cavity Numbers Single / Double Polish Mirrior Polish Deliery by Sea or Air Mould Material P20 / 718 / 2738 Machining CNC, EDM, Deep Hole Drilling Injection Machine Haitian Mould Life 1 Million Shots Mould Standard Lkm, Hasco Sample Time 45-60 Days Transport Package Wooden Case Specification International Trademark REMO Origin Taizhou China HS Code 8480719090 Production Capacity 100 Sets/MonthProduct Description

TaiZhou Remo is one of the most experienced battery case mould maker in China. For the past 10 years, Remo has exported more than 100 models to the world including USA, Russia, Brasil, Turkey, Portugal, Spain, Italy, India and Pakistan.We have the most advanced technology for car mould and the most experienced workers for these moulds.

Our advantages:

1; 10 years employees for battery case mould making

2; Over 200 battery case mould experience every year

3; Over 10 countries of different battery case models

4; Excellent Cooling System with extended cooling pipe

5; Copper Cooling for better cooling effects

6; Pre-opening system to improve cycle time

7; Semi-Hot Runner System to save clients cost on moulds

8; Mould Avaliable for recycle Material

9; Excellent control of polish system

10; Weekly report with mould processing photos available

11; Samples and each trial out video available

12; Punctual sample time and delivery time

13; Logistic service available

14; Engineers available in client's factory for training

15; High quality mould with resonable price

Name Description

Products' info we need to make quotation Clear Pics/material/size/weight/wall thickness/targetting quantity and etc.

Mould Material 45#, 50#, P20, H13, 718, 2738, NAk80, S136, SKd61 etc

Mould Base LKM, HASCO ect.

Cavity Single/multi

Runner Hot/cold

Mould Design 3D/2D Drawing

Design Days 3 days

Design Software UG, PROE, CAD, CAE, CAM, CAXA ect

Plastic Material PP, PC, PS, PE, PU, PVC, ABS, PMMA ect

Mould Life 300, 000-3, 000, 000 shots

Injection System Pin-point-gate

Polish System Mirror Polish

Payment 40% of Deposit by T/T, 60% of Balance by T/T

Delivery Time 15-60days

Specification Depends on customers requirements

| Name | Description |

| Products' info we need to make quotation Clear | Pics/material/size/weight/wall thickness/targetting quantity and etc. |

| Mould Material | 45#, 50#, P20, H13, 718, 2738, NAk80, S136, SKd61 etc Mould Base LKM, HASCO ect. |

| Cavity | Single/multi |

| Runner | Hot/cold |

| Mould Drawing | 3D/2D Drawing |

| Design Days | 3 days |

| Design Software | UG, PROE, CAD, CAE, CAM, CAXA ect |

| Plastic Material | PP, PC, PS, PE, PU, PVC, ABS, PMMA ect |

| Mould Life | 300, 000-3, 000, 000 shots |

| Injection System | Pin-point-gate |

| Polish System | Mirror Polish |

| Payment | 40% of Deposit by T/T, 60% of Balance by T/T |

| Delivery Time | 15-60days |

| Specification | Depends on customers requirements |