Yg6/Yg8/Yg10/Yg15 Tungsten Cemented Carbide Extrusion Punches Die for Power Metallurgy

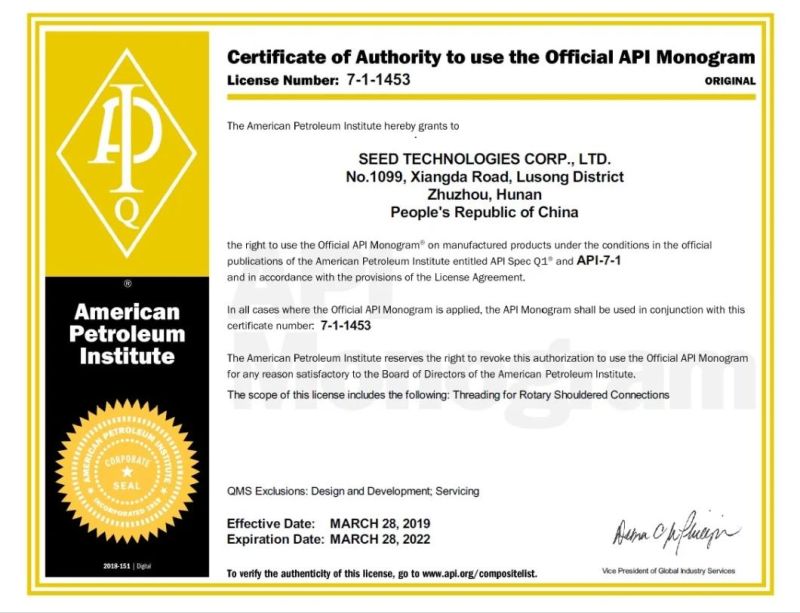

SEED TECHNOLOGlES CORP., LTD.- Technics:Per Customer Requirement

- Processing Method:Per Customer Requirement

- Material:Tungsten Carbide

- Application:Metal Machining and Wear Parts

- Process Combination:Per Customer Requirement

- Manufacturing Technology:Per Customer Requirement

Base Info

- Cobalt Percentage:From 3% to 30% Based on Different Grades

- Grain Sizes Selection:Ultra Fine, Fine, Medium, Coarse

- Surface Finishing:Polished and Unpolished

- Grade:K10,K20,K30,K40,Yl10.2,Yg6,Yg6X,Yg8,Yg10X,Yl10.2

- Customized:Per Your Requirement

- Advantage:High Rigidity & Durable

- Service:Customize ODM OEM

- Features:Wear-Resisting Long Life

- Parts Detection Method:Per Customer Requirement

- Milling Speed:Per Customer Requirement

- Mold Cavity Technology:Per Customer Requirement

- Driving Motor Type:Per Customer Requirement

- Wc+Co Powder:100% Virgin Material

- Transport Package:Standard Package , Customize Packing

- Specification:1-300 mm for Length, Width and Thickness

- Trademark:Aseeder

- Origin:China

- HS Code:848190

- Production Capacity:60 Tons Per Month

Description

ISO Grade

Major Product Lines

--> Wear resistant carbide components via powder metallurgy technique

--> Hardfacing (oxy-acetylene spray, PTA, HVOF, etc.) and surface enhancement (phosphating, boronizing, etc.)

--> High-precision machining of metals (S.Steel, carbon steel, Inconel 718, etc.)

--> Additive manufacture