Plastic Injection Daily Necessities Parts Molding for Spoon

Shanghai MY Mould Co., Ltd.- Process Combination Type:Compound Die

- Plastic Material:PC

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Sand Blasting

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Shape:Base on Drawings

- Production Material:as Per Client′s Requirement

- Cavity:as Per Client′s Requirement

- Cycle Time:250s-60s

- Mold Steel:Nak80,SKD61,H13, 1.2344

- Gate Type:Valve Gate,Open Gate,Sub Gate,Edge Gate

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, ISO, FDA

- Installation:Fixed

- Design Software:UG

- Runner:Cold Runner

- Model NO.:w35

- Transport Package:Carton

- Specification:Customized

- Trademark:MYMOULD

- Origin:Shanghai, China

- HS Code:8480719090

- Production Capacity:45 Sets,Month

Description

Mould material

Plastic mould material: P20 steel, 718, 2738,H13, NAK80,2344,2343,S136,etc....

Fast mould design

can be within 1-3 working days after getting customer's drawings

Lead time

Plastic moulds :3- 6 weeks after getting the mould design confirmation

Mould testing

All of the moulds can be well tested before the shipments. Videos for testing the moulds are available.

Minimum order:

small orders can be accepted

Production capacity

45 sets/month

Port

shanghai

Runner

Hot/cold

Payment terms

L/C T/T Western Union Money Gram

Mould making service

OEM/ODM service available

After sales service

Available by our staff with more than 10 years of working experience in this field

Good packages

In strong wooden pallets to avoid any damages during the long transportation

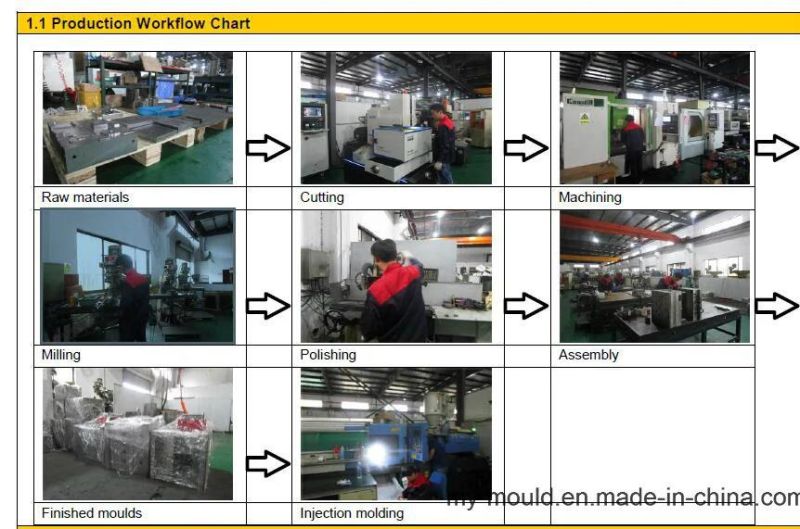

workshop

FAQ:

1.Q: I have an idea for a new product, but I don't know if it can be manufactured. Can you help?

A:Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea o r design and we can advise on materials, tooling and likely set-up costs.

2.Q:What are the advantages to have my parts manufactured locally?

A:Win Win Mold can offer quick reaction times to any changes in specification, batch size or material. We can ship small or large quantities anywhere in North America, Europe overnight to accommodate unforeseen changes in demand.

3.Q: My components have already been developed on CAD. Can you use the drawings?

A: Yes! DWG, DXF, IGES, Solid works and STP, X_T files can all be used to generate quotes, models and mould tools - this can save time and money in producing

your parts.

4.Q: Can I test my idea/component before committing to mould tool manufacture?

A:Yes, we can use CAD drawings to make Prototype models for design and functional evaluations or market test.

5.Q:What type of plastic is best for my design/component?

A: Materials selection depends on the application of your design and the environment in which it will function. W e will be happy to discuss the alternatives and suggest the best material.

6.Q:What type of mould tool do I need?

A:Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend the

best tooling option for you.

7.Q:Ok, I've decided to go ahead with my project. How long will it take to get my parts?

A: It can take 3 to 6 weeks to have the mould tool manufactured depending on the part's complexity, size and the number of impressions/ cavities (single or multiple). After we receive your final approval on the tool preliminary design, you can expect delivery of T1 parts within 3-6 weeks. And during mold building process, mold build Weekly Update will be provided to you every week for your better understanding of the manufacturing progress in our work shop.

Packing

Manufacturing and exporting experience for over 10 years. ISO 9001 approved &TS16949 approved .

Products are supplied to over 50 countries.

One-stop service for aluminum profiles, plastic parts, rubber parts, and moulds. Save time and save money for you.

In-house mold design and building capabilities.

No reclaimed material used to ensure high quality.

Keep secret to your idea and your design.

24 hours (two shifts) / 6 days for production.

Professional design team, mold maker engineer. OEM/ODM service.

Professional QC and R&D teams to assure high quality.

Professional sales team. Good English capabilities and communication skills.

No MOQ.

Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer's urgent demands.

Geographical advantages: within 30 minutes to airport or sea port.