Auto Outside Push Pull Plate Modern Front Rear Door Handle

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Quotation:According to Samples, Drawing and Specific Require

- Color:Silver,Chrome,Black or Follow Customers

- Lead-Time:15-45 Working Days

- Product Material:ABS, PP, PS, HDPE, TPE, TPU etc

- Advantages:10 Years Experience

- Product Name:Car Push and Pull Outside Door Handle

- Customized:Customized

- Standard:PUNCH

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Runner:Cold Runner

- Model NO.:HW-675

- OEM:Logo,Size,Shape Can Be Customed

- Transport Package:Hard Carton, or Customized

- Specification:According to your drawing

- Trademark:OEM

- Origin:Guangdong, China

- HS Code:8480719090

- Production Capacity:8000,Day

Description

Overview

Product Description

Project Management Process:

Mould Design Drawing:

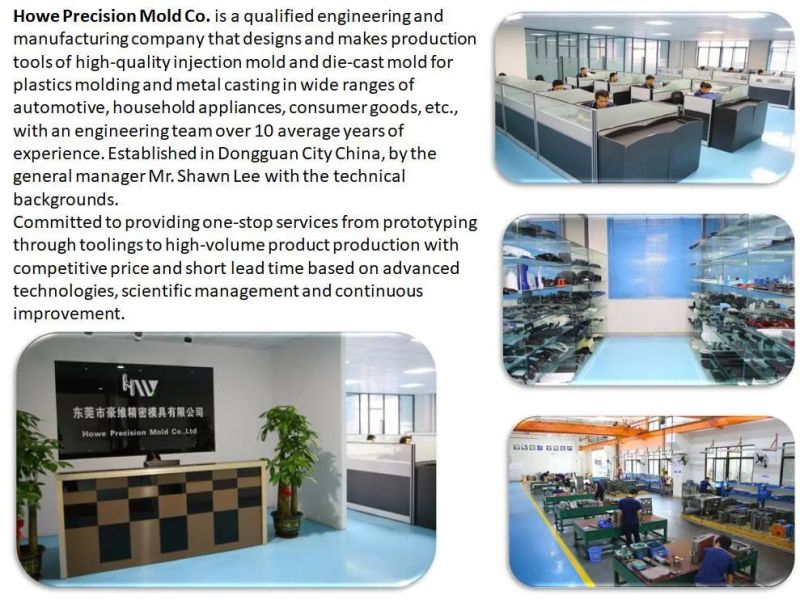

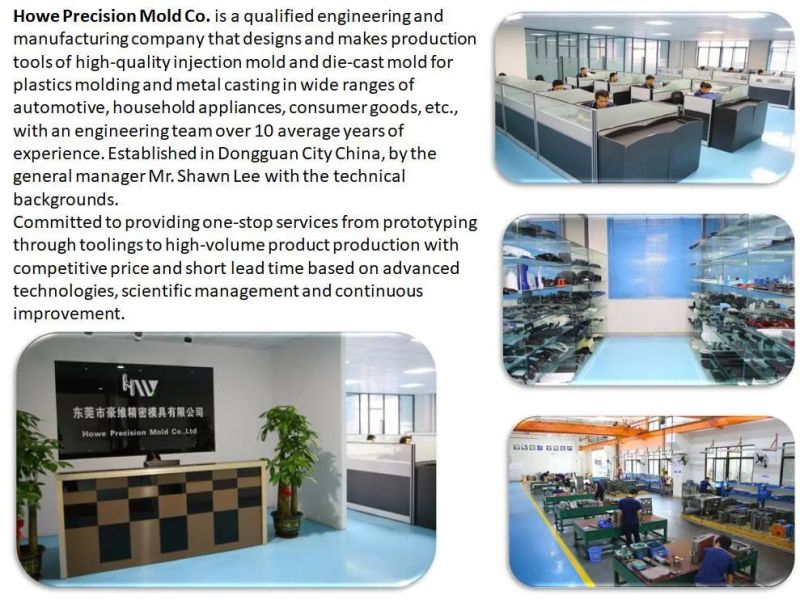

Company Profile:

Family Culture:

Customer Visiting:

Advantage:

1. We are a manufacturer specialized in OEM injection plastic parts from design to rapid prototype to mold to mass production for more than 13 years.

2. Long term cooperation with some Top Brand Auto Industry, such as Volvo and SKODA.

3. We can assemble a complicated products. Providing samples with important dimensions and customizing inspection report material certification to customers for validation and verification.

4. Equipment includes CNC, EDM, grinding machine, injection machine (from 45ton to 1000ton), we can supply high precision and complex injection molds and products .

5. We offer unique solutions to your products at a competitive price and best service.

6. Strict quality control. The factory has the most advanced testing equipment to ensure the precision of the mold.

7. Your products will enter the supermarket, we can design a package for you.

8. Quick mold making and on-time delivery.

9. We accept small order quantity, look forward to receiving your inquiry.

10. Excellent R&D teams, Professional technicians and rich experienced workers

11. Providing good After-sale service, if the products have any quality problems, we will take charge of it.

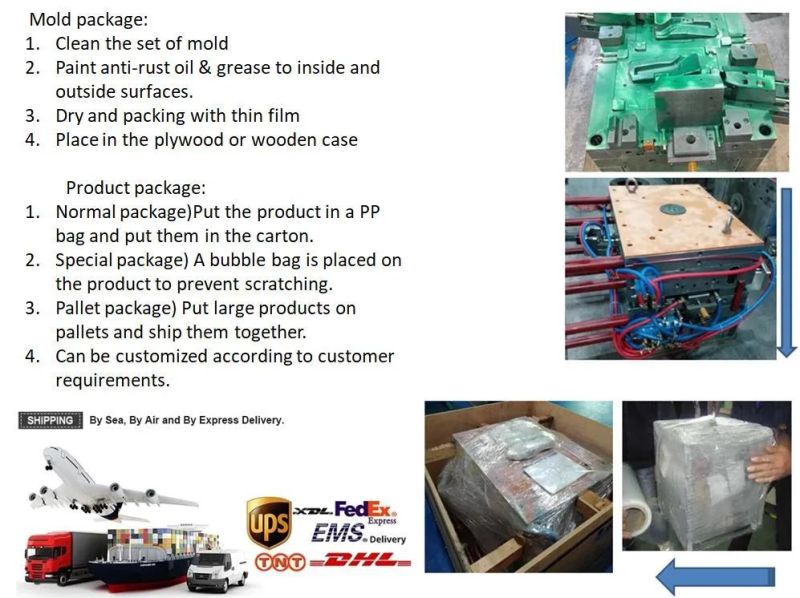

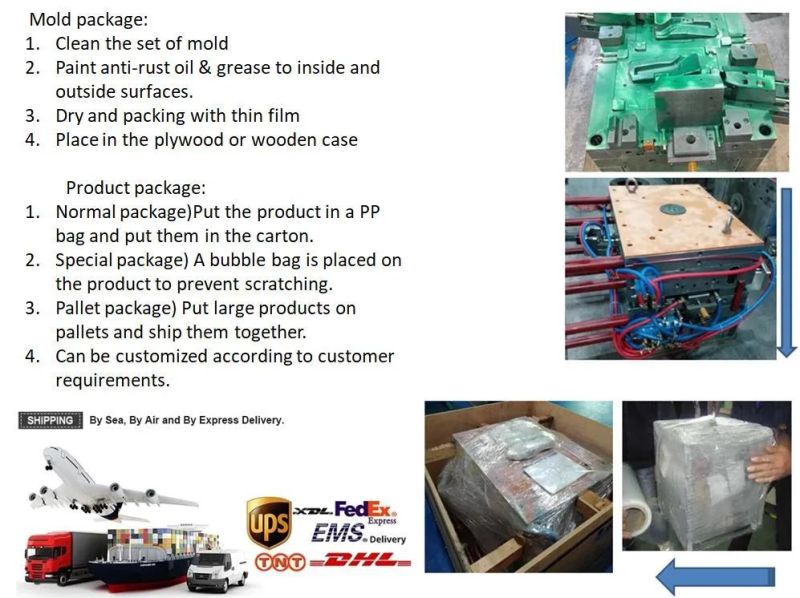

Packing & Shipping:

Detailed Photos

Project Management Process:

Mould Design Drawing:

Company Profile:

Family Culture:

Customer Visiting:

Advantage:

1. We are a manufacturer specialized in OEM injection plastic parts from design to rapid prototype to mold to mass production for more than 13 years.

2. Long term cooperation with some Top Brand Auto Industry, such as Volvo and SKODA.

3. We can assemble a complicated products. Providing samples with important dimensions and customizing inspection report material certification to customers for validation and verification.

4. Equipment includes CNC, EDM, grinding machine, injection machine (from 45ton to 1000ton), we can supply high precision and complex injection molds and products .

5. We offer unique solutions to your products at a competitive price and best service.

6. Strict quality control. The factory has the most advanced testing equipment to ensure the precision of the mold.

7. Your products will enter the supermarket, we can design a package for you.

8. Quick mold making and on-time delivery.

9. We accept small order quantity, look forward to receiving your inquiry.

10. Excellent R&D teams, Professional technicians and rich experienced workers

11. Providing good After-sale service, if the products have any quality problems, we will take charge of it.

Packing & Shipping: