Auto Plastic Injection Tooling Rearview Mirror Mould

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Painting

Base Info

- Specification:750*650mm

- Transport Package:Wooden Cases,Air,Sea

- OEM:OEM

- Lifetime:1 Million Shots

- Lead Time:4-6 Weeks

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, CE, ISO, FDA

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:HW-059

- Trademark:Customized

- Origin:China

- HS Code:8480719090

- Production Capacity:50sets,Month

Description

Plastic Mold (Moulds) production process

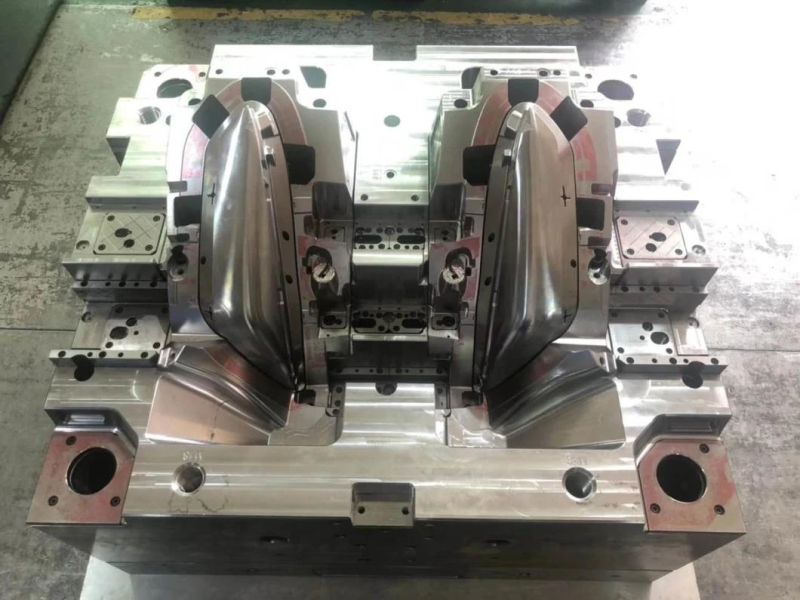

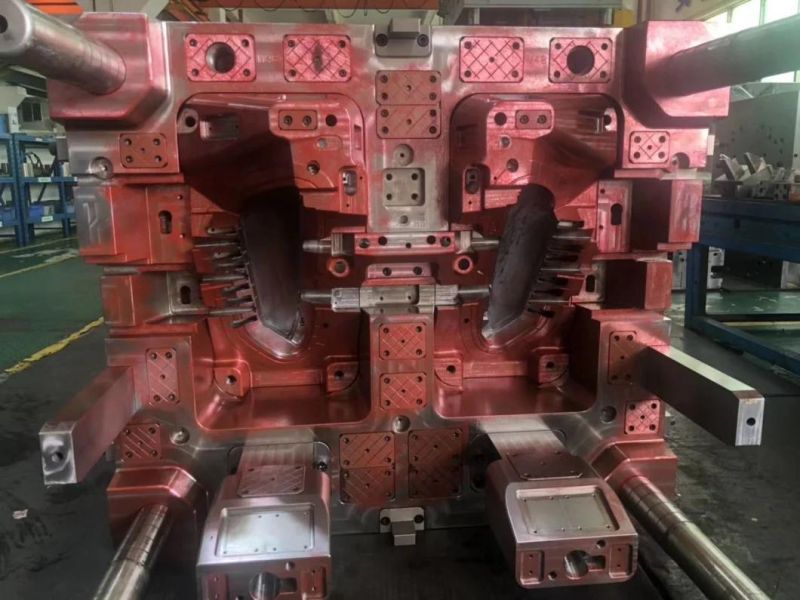

Mold pictures

Howe has been a key supplier to some of the most well known automotive OEMs Howe's infrastructure of complete resources allows our clients to focus on what's most important to the automotive market-zero defects, and lowering overall costs

Our Services

Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception.Is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards.Our team of CAD designers will ensure that your imagination is incorporated into the actual product! If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!Our products include :

1.Custom Plastic Injection Parts

2.Multi-cavity plastic parts

3.High Precision Molds

4.Insert & over molding

5.Double Shot Mold(2K mold)

6.Unscrewing Molding

7.Gas-assisted Molding

8.Die Casting Molding

9.Prototype plastic parts and Low cycle plastic parts molding

10Gas Assist molding

11.Elastomeric molding

12.IML & IMD part production

13.Thin wall plastic molding

14.High temperature molding

Why Choose Us

1. We have our own design and development team and factory, with more than 10 years of product production experience. Familiar with and good at developing business with overseas market.

2. We can provide OEM/ODM services for all kinds of customers, and our professional support team will provide services for customers 24 hours a day.

3. We have a very strong quality control system to ensure the best quality of our products, the best service and competitive price.

4. Samples are always available for quality inspection and can be sent to you very quickly.

5. Design ability: design according to customer requirements.

6. We deliver goods on time and cooperate with customers sincerely.

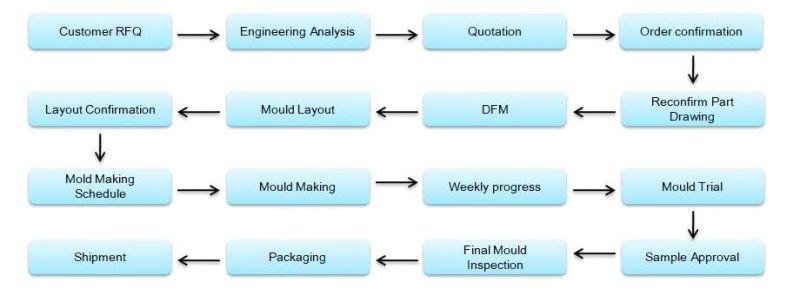

Project Management Process

Inspection Method

We will provide fully dimension checking before mold test.

Make sure all components and mold dimension under correct tolerance. if customer needed, we can provide all these documentation for their reference.

Packaging & Shipping

FAQ

Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: If you make poor quality goods,will you refund our fund?

A: As a matter of fact, we won't take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.

For more information, please contact us ! Thanks !