Wood Pattern of Concrete Stamp Mould Floor Mould

ZHENGZHOU LYA MACHINERY CO., LTD.- Cavity:Single-cavity

- Manufacturing Processes:Injection Mould

- Application:Home Use, Household Appliances, Driveway, Pool Deck, Patio,Wall

- Product Type:Household Goods

- Surface Treatment:Paint

- Working Temperature:(-60℃-200℃)

Base Info

- Transport Package:Plastic Bags, Wooden Box

- Pattern:Rock, Cobblestone, Wooden

- Color:Green, Blue, Yellow, Black, Orange

- Raw Material:PU

- Weight:Depend Designs

- Customized:Customized

- Warranty:3 Years

- Mould Life:50000 Times

- Certification:CE, RoHs, UL, FDA, REACH

- Model NO.:LY-2

- Specification:Customer Size Accepted

- Trademark:LYA

- Origin:Henan, China

- HS Code:8480600000

- Production Capacity:10000 Piece,Week

Description

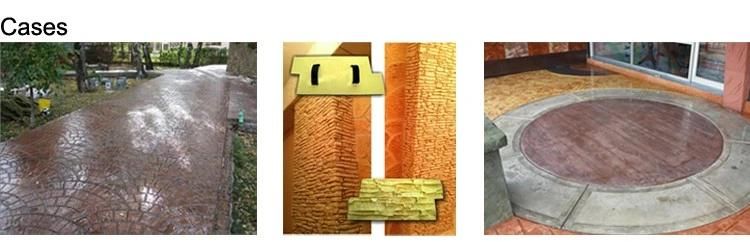

to add a unique flair to your driveway, pool deck, patio, walkway or walls.

Set Quantity: 4 pcs (3rigid+1flex) is available.

6 pcs(5rigid+1flex) is better to make beautiful path.

Product Description

Floor / Wall Stamped Concrete is the process of pressing decorative or natural impressions into wet concrete using rubber stamps. This is a great way to add a unique flair to your driveway, pool deck, patio, walkway or walls.

Benefits of using stamped concrete.

1. Concrete is one of the most durable building materials available for paving, which comes in handy in high traffic areas such as driveways and walkways.

2. Choosing stamped concrete over other paving materials such as natural stone can be a more economical choice. Done right, stamped concrete can look just as high quality as these other methods. For instance, a stamped concrete job can be installed in a portion of the time as natural materials takes, which allows contractors to be more productive.

3. The biggest advantage to stamped concrete is the flexibility.

Concrete stamping, combined with different finishing techniques, allows for unlimited design opportunities such as aged cobblestones, brickwork, flagstones, slate tile, marble, granite, wood, or just about any natural surface.

Click for More detail !!!

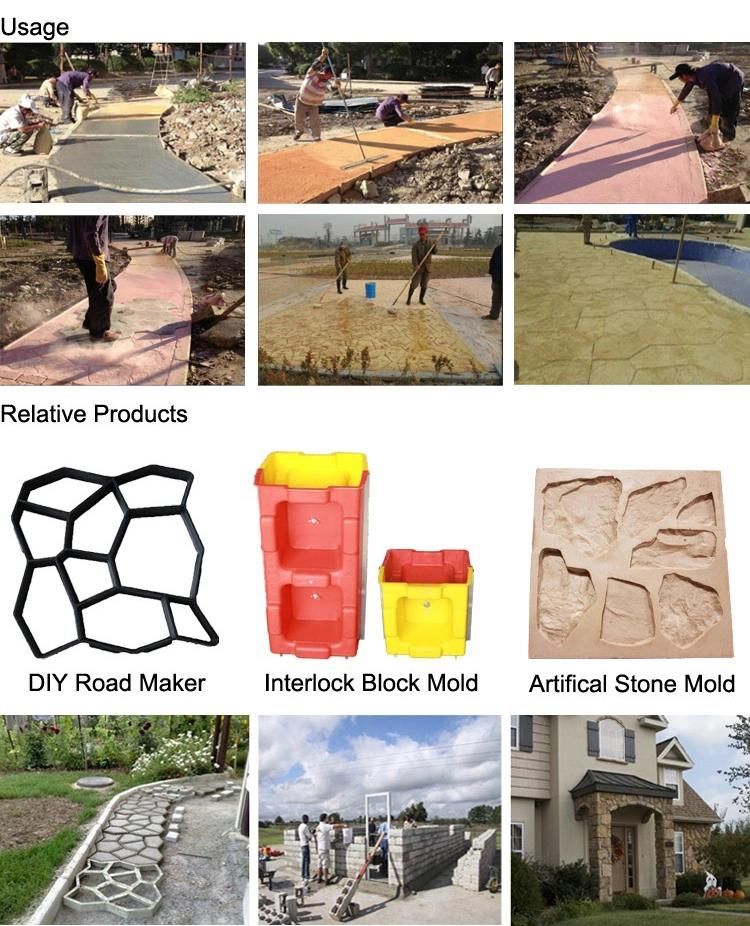

How to used the stamped concrete?

In advance you can broadcast your powder release agent onto the surface of the concrete stamp. Once your concrete is installed and at the concrete's optimum degree of set, you can begin stamping. (approximately the brooming stage) Place these on the surface to be stamped, and just place your seamless texture mats right over these mats. Great force should not be necessary to press the mat into the wet concrete. Since, time is of utmost importance in decorative stamping, you should begin and proceed without delay. Coat your stamp with powder release after each application.

Bubble gum liquid release may be used as a substitute to the powder release. The bubble gum liquid release is a much easier and cleaner method but will leave no secondary antiquing color highlights which are achieved with the powder method. The decorative concrete should then be left to set for at least 24 hours.

At the end of this period, the excess powder release (if used) should be washed off the surface of the concrete. Approximately 15-20% of the colored release agent will adhere to the concrete. Allow to dry and seal with a good quality concrete sealer. Sealer brings out the richness of the color and prevents the color from fading and staining.

Company Information

we are Zhengzhou LYA machinery company, from China, and our company specialized in producing PP,ABS, PVC & Rubber moulds,artificial stone which covers a great range, including plastic paver mould, curbstone mould, flower pot mould, roman pillar mould, vase mould, concrete stamp mould and Silicone culture stone mould, the mould is perfect for road pavement, house and Garden decoration, stamp landscaping and villa culture stone decoration.

In the Past 6 years, our products have already distributed to USA, UK, UAE, Qatar, Oman, Saudi Arabia, Philippines, Thailand, Ethiopia, Kenya, Somalia, Congo, Ghana, Gabon, Brazil and France.

We constant insist on the principle : Traffic Safety & City Beauty. We believe that the quality is our culture and effort to be the leader of led lighting in the world.

Our main product is

FAQ

1. Can you make custom designed products?

Yes, we can according to customer requirements, such as shape, size, color, pattern and other details of the product to make.

2. How could I know the price of the item?

If you want to know our normal products, you just tell us the item number and your information, I'll give you the best price.

If you have individual design requirements, please tell us the following information so that we can offer the price immediately.

1) Product model and measurements (you better have drawings, samples or photos).

2) The expected delivery time.

3) Your contact details information.

3. What is the MOQ ?

Under normal circumstances, there is no limited to MOQ. It is subject to our esteemed customers. More quantities, the price is more better.

4. How could I get the samples?

For the first cooperation, we ask the samples fare + shipping cost, and we will give back the cost after the customer place the order.

For the regular cooperation customers,we offer free

sample fare+shipping cost .

5. How can I install these samples?

We will send you the installation procedures including the video or picture for you reference. You can also call our hot line.

Conctact Us