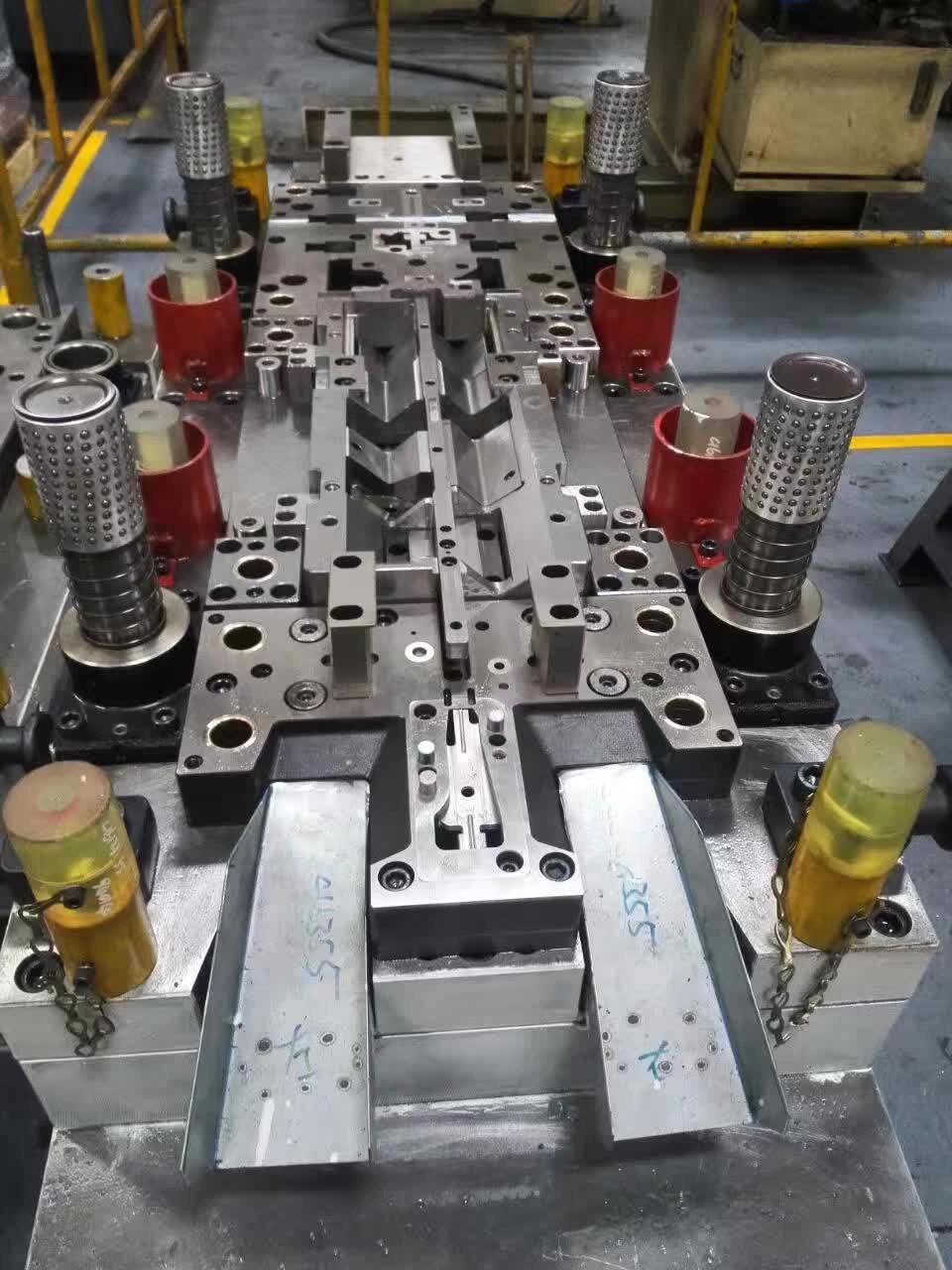

Progressive Die for Auto Parts Mould Precision Molds

Zhongshan Huihai Mold & Automatic Equipment Co., Ltd.- Process Combination:Progressive Die

- Technics:Forming Die

- Processing Method:Punching and Shearing Mould

- Material:Hard Alloy and Steel Bonded Carbide

- Application:Car

- Manufacturing Technology:Computer Technology

Base Info

- Certificate:ISO9001:2008, SGS

- Mould Material:Cr12, Cr12MOV, DC 53, Skh-9, 45# etc

- Design Software:2,3 D, Auto CAD, Cae, PRO-E, Solidworks, Ug

- Cavity:1 to Multiple

- Tolerance:+-0.01mm

- Model No:Hh043

- Customized:Customized

- Packing:Wooden Case

- Lead Time:35 Days

- Name:Punching Mold for Custom Sheet Metal Stamping

- Parts Detection Method:Geometric Detection

- Milling Speed:Normal Speed

- Mold Cavity Technology:CNC Milling

- Driving Motor Type:Permanent Magnet

- Model NO.:SM020

- Transport Package:Wooden Case

- Specification:SGS, ISO

- Trademark:huihai auto

- Origin:Zhongshan

- HS Code:8207209000

- Production Capacity:350 Sets,Year

Description

Basic Info.

Model NO. SM020 Driving Motor Type Permanent Magnet Mold Cavity Technology CNC Milling Milling Speed Normal Speed Parts Detection Method Geometric Detection Name Punching Mold for Custom Sheet Metal Stamping Lead Time 35 Days Packing Wooden Case Customized Customized Model No Hh043 Tolerance +-0.01mm Cavity 1 to Multiple Design Software 2/3 D, Auto CAD, Cae, PRO-E, Solidworks, Ug Mould Material Cr12, Cr12MOV, DC 53, Skh-9, 45# etc Certificate ISO9001:2008, SGS Transport Package Wooden Case Specification SGS, ISO Trademark huihai auto Origin Zhongshan HS Code 8207209000 Production Capacity 350 Sets/YearProduct Description

Our Advantages:

1. Competitive price

2. Strict quality control system (ISO9001 system manage)

3. Quick mold making and delivery (4-7weeks)

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers

Huihai specializes in manufacturing and supplying of various moulds and dies, such as metal stamping dies, plastic injection moulds, motor stator&rotor molds and stamping parts and injection parts since 2005.

Huihai provides various molds & dies to the clients from USA, Spain, Italy, Russia and so on.

"Good quality with cost-effective" is the base of Huihai business. Huihai people keep creating value for customers as our mission.

ISO 9001: 2008 certificated.

Special info.:

Customized design according to customer part design or sample.

Mold base: Standard mould base or customized

Inserts(cavity and core): Cr12mov, SKD11, D2, M2, DC 53, SKH-9, Copper alloy or the material you required.

Standard parts: MISUMI, PUNCH, DAYTON, DANLY (Japan or Europe US)

Part material: SPCC, SPCE, SPCD, DC01, DC04, Stainless steel 304.430.316, Aluminum alloy, and so on

Lead time of first samples: Around 4~7weeks.

Products Show:

Our Equipments:

Our Certifications:

we have had the mould experiences for more than 10 years with the professional drawing

designers and professional punching mold machinery process, and we sincerely hope we can build

friendship of trade relation in the near future!

For more information and question, please feel free to contact below fast contact: