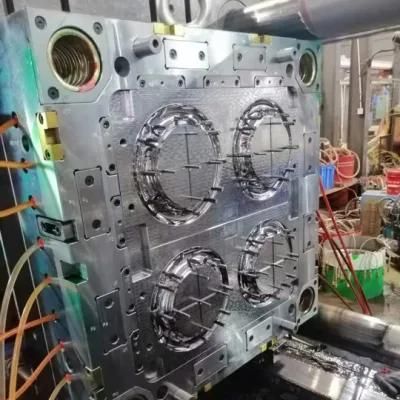

Hot Runner Injection Mold 4 Cavity Molding Plastic Parts

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Lead Time to T1 Sample:4~5 Weeks

- Mold Type:Insert Mold, Over Mold, Shuttle Mold

- Hot Runner:Moldmaster, Incoe, Yudo, Heitec, Gunther, etc

- Package:Wooden Case Package

- Finish:Pitting The Word, Mirror Finish, Matte Surface

- Process:Injection Molding

- Mould Material:S136,Nak80,P20,738,etc

- Mould Life:300K-500K Shots

- Product Name:Plastic Injection Mould

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Cold Runner

- Model NO.:HW-987

- Lead-Time for Production:1~2 Weeks

- Transport Package:Wood Box and Wood Pallet

- Specification:According to your drawing

- Trademark:Custom

- Origin:Guangdong, China

- HS Code:8480719090

- Production Capacity:40sets,Month

Description

PLASTIC INJECTION MOULD BASIC DESCRIPTIONInjection System Hot /Cold Runner Inserts(cavity and core) H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required. Mold Cavity 1*1,1+1,1*2,1+1+1,etc Gate type Side gate,Sub gate,Pin point gate,Edge gate etc Ejector System Stripper plate,Lifter,Push bar,Ejection pin etc Steel Standard FINKL,Assab,DAIDO,LKM,Buderus Cooling Baffles/Sprin Piple/3D printing water line Lead time of first samples Around 4~7weeks Standard Parts/Cylinders DME/HASCO/PROGRESSIVE/MISUMI/Parker/HP/Merkle Design Capability DFM,Mould flow analysis,Product optimization, Full 2D & 3D mould design,Reverse engineering,Collaborative design with customer's idea Documents / Reports Provided Fully drawing,Weekly Processing Report, Steel Dimension report, Processing Report,Sample Dimension Report. BACK TO HOMEPAGE FOR MORE PRODUCTS!