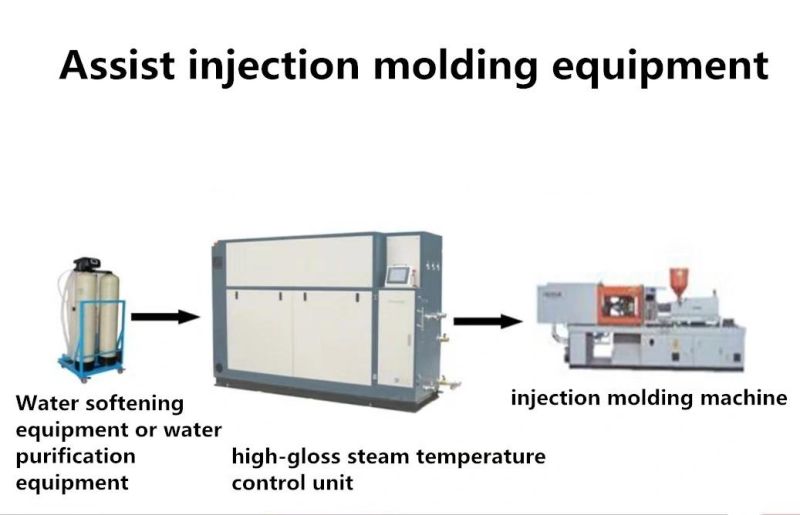

Mould High-Gloss Steam Temperature Control Unit Equipment for Injection Moulding Machine

Zhang Jia Gang Stone Mechanical Equipment Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware, TV, Laptop Panel

- Process Combination Type:Single-Process Mode

- Plastic Material:PC+ABS

- Mould Cavity:Single Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Mirror Polishing

Base Info

- Specification:290× 80× 180CM

- Transport Package:Wooden

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO

- Installation:Fixed

- Design Software:UG

- Runner:Steam

- Model NO.:160L

- Trademark:STONEPACK

- Origin:China

- Production Capacity:1MPa

Description

Basic Info.

Model NO. 160L Runner Steam Design Software UG Installation Fixed Certification CE, ISO Standard HASCO Customized Customized Transport Package Wooden Specification 290× 80× 180CM Trademark STONEPACK Origin China Production Capacity 1MPaProduct Description

Description of equipment features:Advantages in production cycle:

The medium steam (enthalpy 2777.67 KJ) used in our high-gloss trackless equipment is super hot water (enthalpy 762.84 KJ) about 3.6 times, heating speed.

We are 600L large-capacity gas storage tank, which can ensure sufficient stable pressure when heating in production and prevent the product from stable production due to temperature fluctuation caused by pressure fluctuation.

Advantages in energy consumption:

Energy saving:1 when steam is heated, the temperature of the storage tank can reach about 85ºC through special pipe channels, and the set temperature of 180ºC can be heated rapidly, saving the heating time from the water source of environmental temperature to 85ºC, so as to achieve the purpose of energy saving.

2. Energy saving: conventional heating mode: if the steam inlet valve is opened for 15 seconds, the steam outlet valve is opened for 15 seconds to ensure the mold surface reaches the set temperature.

Our heating mode: if the steam inlet valve is opened for 15 seconds, our company will open the steam outlet valve according to the product conditions

6 seconds or so, and 9 seconds or so for the valve to close and not to output steam.

Control principle: due to the gas end effect, the pressure in the heating channel will be significantly higher than that in the steam flow, and the heating rate of the mold will be faster than that in the conventional heating mode.

Our company's new medium voltage, high pressure, split energy saving control equipment, can effectively shorten the length of heating pipeline, shorten the heating and cooling time, namely shorten the production cycle;At the same time, it saves a lot of heat energy and reduces the production cost.

| Other brands | Our company brands | |

| The heating medium | Superheated water: the temperature is 180ºC | Steam: temperature 180ºC-230ºC |

| Heat content | The enthalpy of 1Kg of superheated water is 762.84 kilojoules | The enthalpy of 1Kg of steam is 2777.67 kilojoules |

| The heating mode | Heat transfer (gradual transfer of heat, slow absorption) | Heat release (instantaneous physical transformation, rapid heat absorption) |

| Heating power | 100-240kw power, high cost for single product | Small power of 80-150kw can be used for high-power products of the same model, with low cost per product |

| Storage volume | The pressure drop of about 300L is large and the production is unstable | Stable pressure of about 600L can guarantee stable production |

| Energy saving way | Small volume heat transfer, large displacement increase electricity load | Large water tank heat exchange, save a lot of electricity |

| Heating mode | Straight in and out, consuming heat | Reasonable control of export time to save energy |

| Control line | Copper pipe, easy to corrosion lead to damage of gas path components | Stainless steel tube, prevent corrosion and pollution of gas path |

| Spare parts | Vulnerable parts welding, modular parts, replacementTrouble affects production | Vulnerable parts modular, easy to replace |

| Electrical appliances brand | Zhengtai, Omron(counterfeit), etc | ABB, Schneider, Siemens, etc |

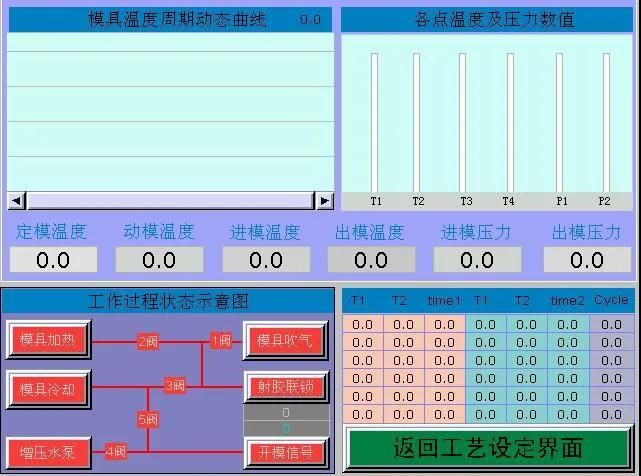

ST-2000 series mold variable temperature steam thermal efficiency control system main operation interface display:

Operation panel language in Chinese and English

ST-2000 series mould variable temperature steam thermal efficiency control system

★Boiler water source input: 0.20 tons/hour;It is recommended to use softened water or purified water, user piping;

★Power access: 380V 3-phase 5-wire.Recommended cable section > 105mm2, the user is equipped with cable;

★Cooling water inlet and outlet: water temperature below 250C, softening water quality;Stainless steel temperature resistant pipe is recommended.

★ compressed air input: air pressure is 0.6-0.8mpa, which needs to be freeze-dried to remove water and filter and dust;

★Mold interface: users should be equipped with the corresponding pipes and water drainage according to the mold, waterway structure, it is recommended to use stainless steel temperature resistant pipes.

product case:

For faster and more information, please add whatsapp:+86 18550896679