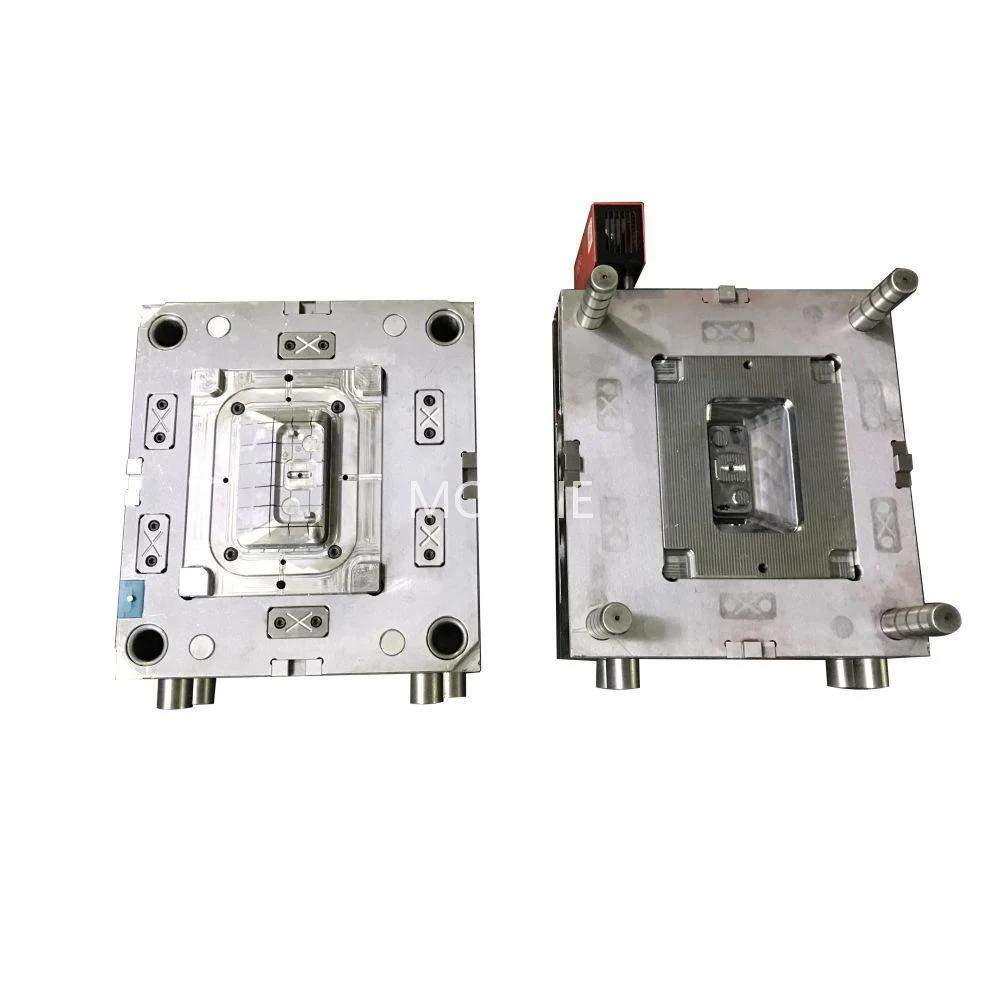

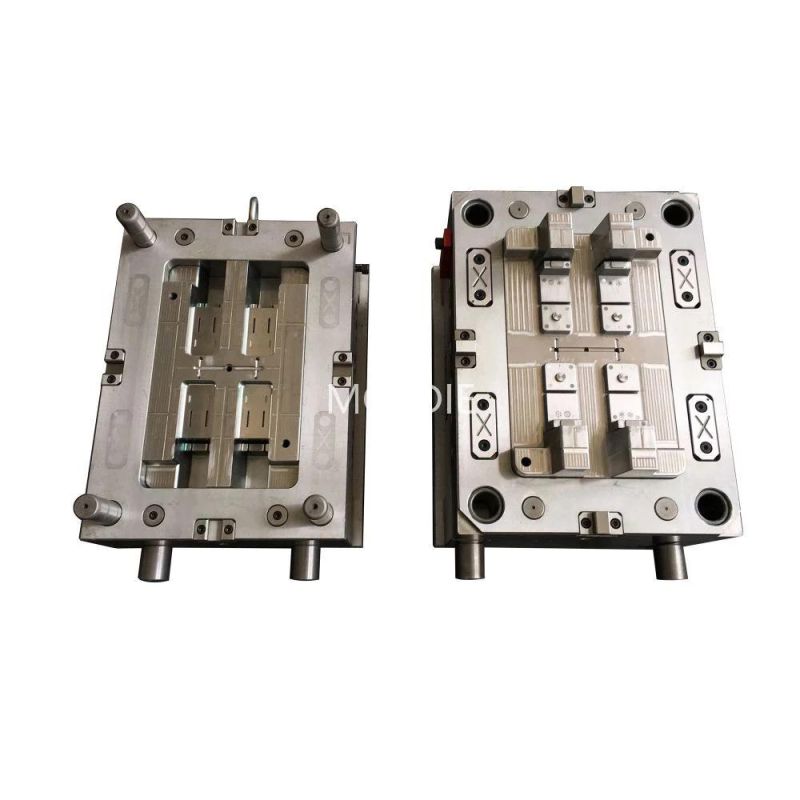

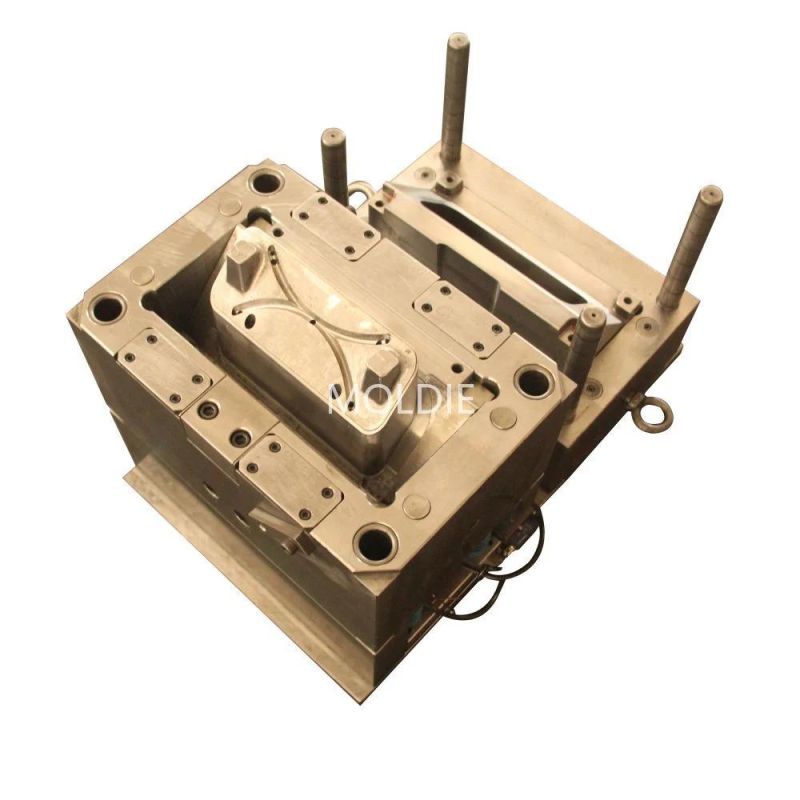

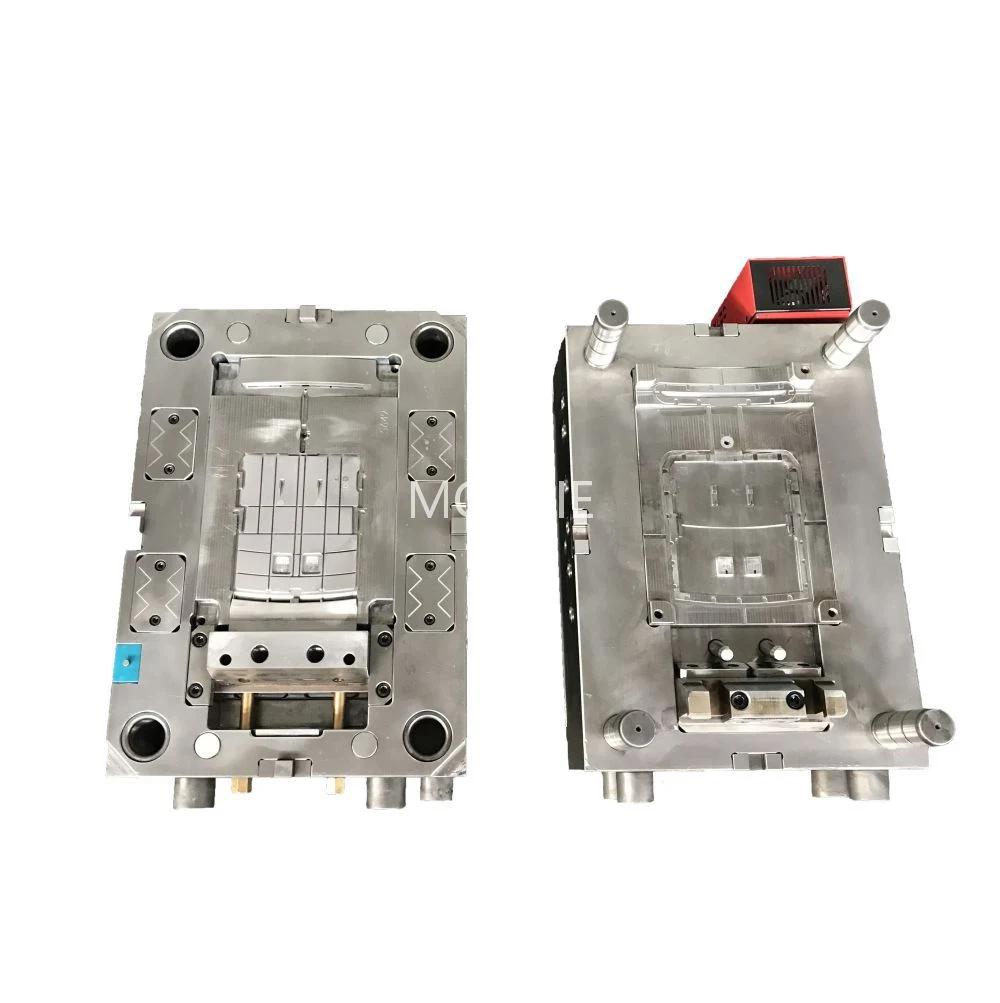

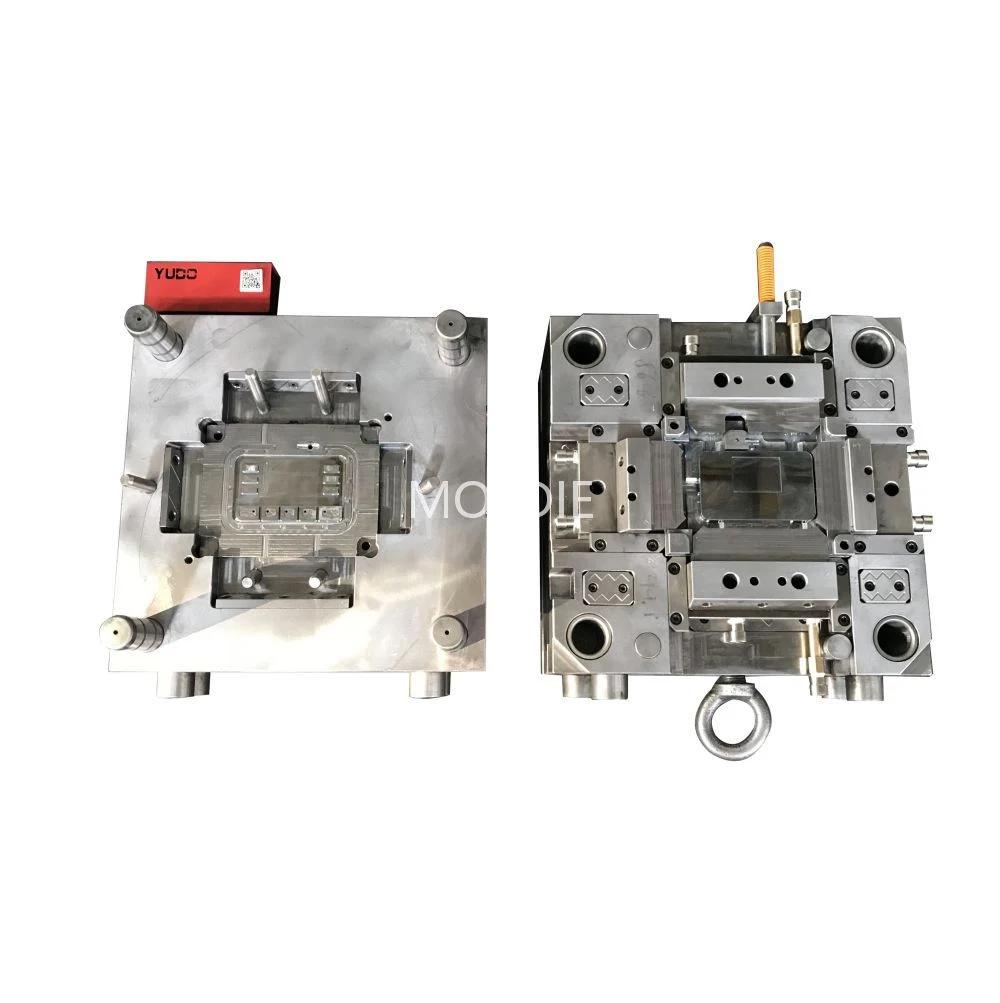

Customized/Designing Plastic Injection Molds for Electrical Box Cover

Ningbo Moldie Mold Co., Ltd.- Plastic Material:Customized

- Mould Cavity:Customized

- Surface Finish Process:Customized

- Shaping Mode:Injection Mould

- Warranty:1 Year

- Process Combination Type:Single-Process Mode

Base Info

- Transport Package:Customized

- Tolerance:0.01mm

- Shape:Customized

- Color:Customized

- Mold Material:P20, 718, H13, 2316, Nak80 and So on

- Brand:Customized

- Lead Time:4-5 Weeks

- After-sales Service:Accept

- Customized:Customized

- Standard:Customized

- Certification:ISO

- Installation:Mobile

- Design Software:UG

- Runner:Customized

- Application:Electronic, Home Use

- Model NO.:Customized

- Specification:Customized

- Trademark:MOLDIE

- Origin:Ningbo, China

- HS Code:8481707090

- Production Capacity:50 Sets Per Month

Description

Basic Info.

Model NO. Customized Application Electronic, Home Use Runner Customized Design Software UG Installation Mobile Certification ISO Standard Customized Customized Customized After-sales Service Accept Lead Time 4-5 Weeks Brand Customized Mold Material P20, 718, H13, 2316, Nak80 and So on Color Customized Shape Customized Tolerance 0.01mm Transport Package Customized Specification Customized Trademark MOLDIE Origin Ningbo, China HS Code 8481707090 Production Capacity 50 Sets Per MonthProduct Description

Specifications1. OEM/ODM service

2. Quick delivery

3. Competitive price

4. Strict quality control system

5. Experienced with US. And Europe

OEM & ODM by customers' design, quote according to your drawing and samples

Our engineer team manage from part drawing until shipment and check each step to make sure the final Products are qualified before shipment.

MOLDIE with its factory has more than 10 years experience for various mechanical stamping parts.

"Good quality" is the base of MOLDIE business, as all MOLDIE staff know quality is essential Condition for mechanical products, MOLDIE must keep our clients in a safe condition.

ISO 9001: 2008 certificated.

Since 2007, MOLDIE starts exporting various plastic parts to Germany, Spain, Italy, USA and so on.

Our engineer team manage from part drawing until shipment and check each step to make Sure the final products are qualified before shipment.

To he plastic products, we also can make the mold for your products, and we will send the Sample to you, we will start produce the products after you are satisfied with the sample.

Advantages:

1. Quick delivery

2. Low quantity is acceptable

3. Strict quality control system.

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers.

| Name | Plastic parts |

| Working Process | stamping, deep stamping, bending, punching, threading,welding, tapping, riveting |

| Material | ABS, PC, PP, PS, POM, PMMA,PE,AS,PPSN,PBT,PA66,PC/ABS.etc |

| Mould Base Material | LKM, FUTABA, HASCO, etc. or as per customer' s requirement. |

| Surface treatment | powder coating, polishing, chrome plating |

| Color | white,black or as per customer's requirement |

| Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

| Applications | All kinds of cars, machinery, home appliance, electronic products, medical devices, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more |

| Quality Control | Conducted by ISO9001 |

| Cavity Number: | Single cavity, Multi Cavity, based on customer' s requirement. |

| Equipments: | CNC, EDM, ArgieCharmilles, Milling Machine, 3D CMM, Projector, HG, Injection Machine |