Stamping Tooling/Mould for Microwave Oven

Zhongshan Huihai Mold & Automatic Equipment Co., Ltd.- Processing Method:Punching and Shearing Mould

- Material:Carbon Tool Steel

- Application:Household Appliances, Hardware, Home Use

- Technics:Cutting Die

- Process Combination:Single-Process Mould

- Manufacturing Technology:Computer Technology

Base Info

- Specification:SGS, ISO

- Transport Package:Wooden Case

- Stamping Material:Stainless Steel, Aluminum Alloy, Brass, Copper etc

- Mould Material:Cr12, Cr12MOV, DC 53, Skh-9, 45# etc

- Design Software:Auto CAD, Cae, PRO-E, Solidworks, Ug etc

- Standard:Hasco, Dme

- Tolerance:+-0.03mm

- Model No:Hh076

- Customized:Customized

- Packing:Wooden Case

- Lead Time:42 Days

- Name:Stamping Tooling,Mould Manufacturers in China

- Parts Detection Method:Measurement of Three Axis NC

- Milling Speed:Normal Speed

- Mold Cavity Technology:CNC Milling

- Driving Motor Type:Permanent Magnet

- Model NO.:HH076

- Trademark:huihai auto

- Origin:Zhongshan

- HS Code:8207209000

- Production Capacity:380 Sets ,Year

Description

Basic Info.

Model NO. HH076 Driving Motor Type Permanent Magnet Mold Cavity Technology CNC Milling Milling Speed Normal Speed Parts Detection Method Measurement of Three Axis NC Name Stamping Tooling/Mould Manufacturers in China Lead Time 42 Days Packing Wooden Case Customized Customized Model No Hh076 Tolerance +-0.03mm Standard Hasco, Dme Design Software Auto CAD, Cae, PRO-E, Solidworks, Ug etc Mould Material Cr12, Cr12MOV, DC 53, Skh-9, 45# etc Stamping Material Stainless Steel, Aluminum Alloy, Brass, Copper etc Transport Package Wooden Case Specification SGS, ISO Trademark huihai auto Origin Zhongshan HS Code 8207209000 Production Capacity 380 Sets /YearProduct Description

Cooker stamping tooling/mould manufacturers in china

Huihai auto has manufactured precision, high-quality, reliable and cost-effective single stamping mould and metal progressive stamping mould and part for the automotive and home appliance for more than ten years. Our precision metal stamping mould and progressive stamping mould make your productivity, quality, design and economy as our important consideration. We can design and manufacture the simple or complex stamping dies or moulds fitting your exact applications.

Product Details:

| Name | cooker stamping tooling/mould manufacturers in china |

| Mould Type | single stamping dies, progressive dies |

| custom | can help our customers to customize their own mould drawing |

| Design Software | 2/3 D, Auto CAD, CAE, PRO-E, Solidworks, UG, Catia, MOLDFLOW, ANYCASTING |

| Mould Material | cr12, cr12mov, DC 53, SKH-9, 45# etc |

| Stamping Material | stainless steel, aluminum alloy, brass, zinc, carbon steel, copper etc |

| Die Standard | HASCO, DME |

| Cavity | 1,2, 5,16,50….depends on your application |

| Die Life | 500,000 shots |

| Certificate | ISO9001:2008, SGS |

| Package | wooden case |

| Payment Term | T/T, western union |

| Finish | polishing, heat treatment, TD coating, electroplating, chrome coated, painting, zinc-plating etc |

| Processing machines | CNC machining center, EDM, WEDM, WEDM-HS, linear cutting machine, radial drill, sawing machine, grinding machine, milling machine, lathe, punch etc |

| Inspection Equipments | CMM, Rockwell-hardness-tester, projector, Dial Calipers, slide Calipers etc |

zhongshan huihai automatic equipment company limited offers the professional mould manufacturers' flow:

1. place the mould order and pay the deposit;

2. our drawing or customers drawing;

3. customers check the design and confirm;

4. production process and the sample;

5. customers check the sample and confirm;

6. receive the balance and arrange the shippment;

7. offer afer sales services.

we want to be your preferred metal stamping die andcutting mould and progressive stamping dies builder or parts suppliers, we ensure to deliver quality components to meet your deliveries.

Processing Equipments

| Machine Equipment | QTY | Tapping center | 1 |

| CNC | 5 | Plate shears | 1 |

| WEDM | 2 | Mechanical Press | 13 |

| WEDM-HS | 2 | Hydraulic Press | 2 |

| EDM | 3 | Inspection Equipment | Qty |

| Radial drill | 8 | CMM | 1 |

| Sawing machine | 1 | projector | 1 |

| Grinding machine | 4 | Rockwell-hardness-tester | 1 |

| Milling machine | 2 | Dial Calipers(0-300mm) | 8 |

| Bench drill | 4 | Slide Calipers(0-1000) | 6 |

| lathe | 2 | Pound scale | 1 |

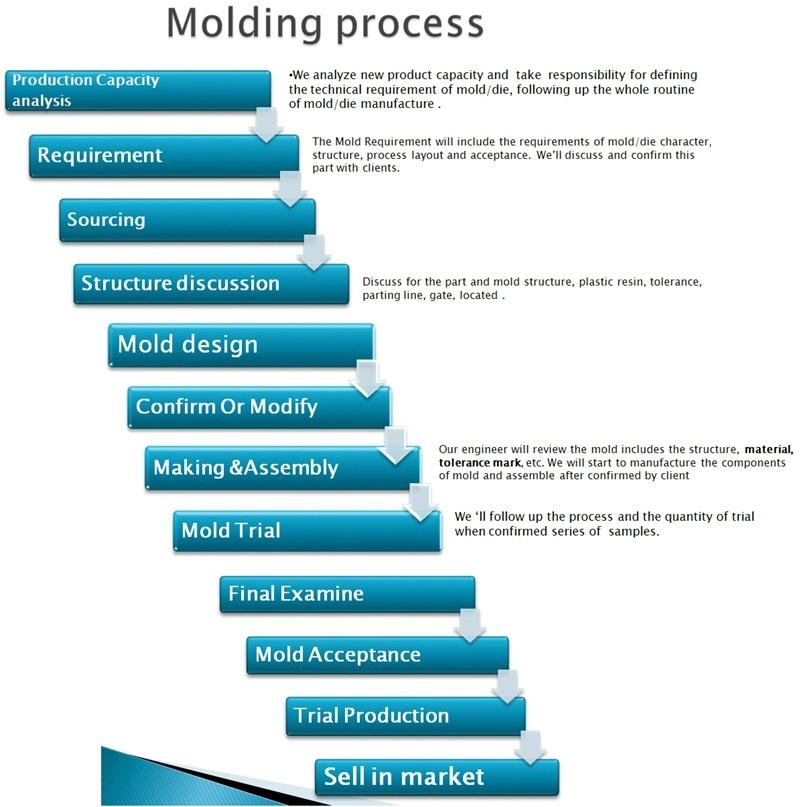

Project process layout

To control the production time, and to decline the probability of clam & return from the end users, making a accurate mold is very important start , we have completed molding produced process to fulfill the needs of client.

Time Control

- Understanding and controlling the factors of any mold making process is the key to fulfill project control, we use computer analysis and specialized division to take care of controlling mold component unit and predicting work hour.

- The Parts we'll take into consideration

Overseas Clients:

WELCOME TO ENQUIRE AND TAKE MORE...