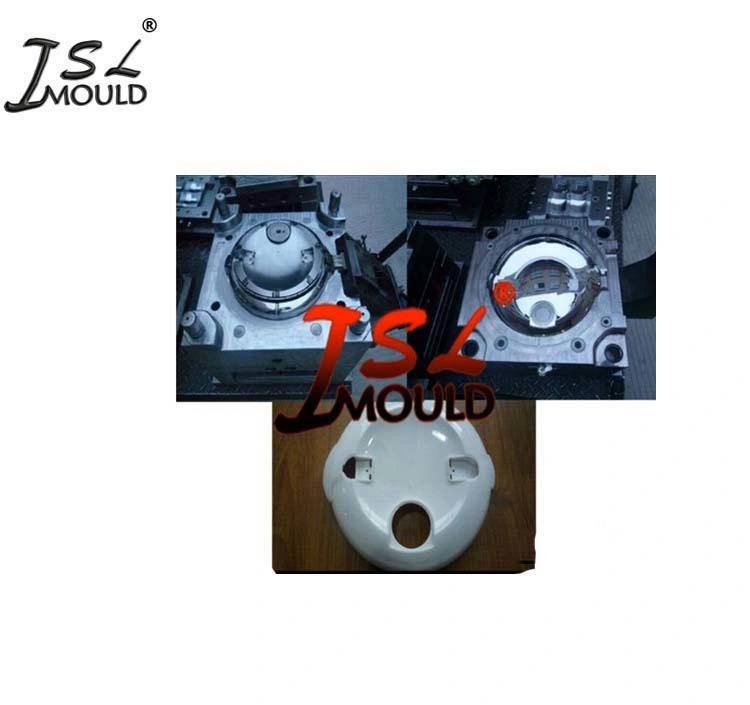

China Professional Rice Cooker Plastic Shell Mould Manufacturer

Taizhou City Huangyan Beiwei Mould Industry Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:PP,PC,ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances

Base Info

- Mould Report:7-10days

- T1 Sample:60days

- Design:7days

- Offer You:OEM&ODM Service

- Offer After Sale Service:Yes

- Mould Operating Mode:Automatically

- Mach Equipment:CNC,EDM,Wire

- Heat Treatment:Nitriding, etc

- Quality Control:in House Professional QC

- Mould Base:S50c,C45

- Customized:Customized

- Standard:Dme,Lkm,Hasco Ect

- Certification:ISO

- Installation:Fixed

- Design Software:Ug,PRO-E,Solidwork

- Runner:Cold,Hot

- Model NO.:JSL-T17616-3

- Transport Package:Wooden Crate

- Specification:Dme

- Trademark:JSLMOULD

- Origin:China

- HS Code:8480719090

- Production Capacity:500 Sets,Per Year

Description

electric cooker shell mould

1.Samples/Drawing &Requirement from you