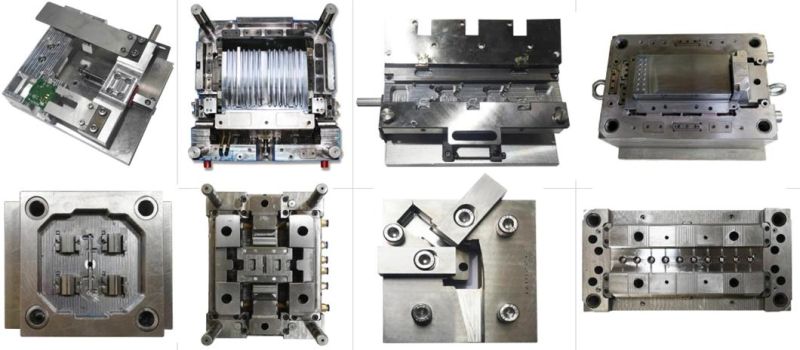

POM Plastic Part Design for Injection Molding

Qingdao Chuangyu Precision Machinery Co., Ltd.- Surface Finish Process:Polishing

- Mould Cavity:Multi Cavity

Base Info

- Color:Black, Silver or According to Customer Request

- Surface Finish:Galvanized(or According to Customer Request)

- Runner:Cold Runner

- Design Software:Pro-E

- Installation:Fixed

- Certification:ISO, Ce, ISO9001, Ce, ISO9001, Ce, ISO9001, Ce, ISO9001, Ce, ISO9001, Ce, ISO9001

- Standard:HASCO, GB, JIS, GB, JIS, GB, JIS, GB, JIS, GB, JIS, GB, JIS

- Customized:Customized, Customized, Customized, Customized, Customized, Customized, Customized

- Condition:New

- Material:Metal

- Technology:Stamping Molding

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery, Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

- Process Combination Type:Single-Process Mode

- Plastic Material:HDPE

- Model NO.:CMP01

- Mode of Transport:Express, by Air, by Sea

- Transport Package:Cartons, Wooden Pallet or Customized

- Specification:up to design

- Trademark:Chuangyu

- Origin:China

- HS Code:7201100000

- Production Capacity:5000pieces,Month

Description

Our professional and exellent workers:

All of our workers have more than 4 years experience and received professional training from Japanese company as to ensure the products quality.

Certification:

Shipment:

We usually delivery the moulds and machinery parts by sea/DHL/FEDEX/TNT, according to the customers.

Factory:

We are a professional manufacturer specializing in plastic injection mould and metal machinery parts machining with rich experience. We can make moulds and plastic/metal parts in variety of fields, such as electronics, automotive, medical, household ect. Our main Products/Services: Machinery Parts/Plastic Injection Mold Design and Making/ In-Mold Decoration. Our Competitive Advantages: Prompt response (respond within 12 hours)/ Complete quality control system for every stage of mould/ Competitive Prices/ Advanced Project Tracking System/ Short Lead Time: 4~7 weeks/Rich Experiences in exporting molds to overseas markets.

FAQ:

1.Q: How to get a quotation?

A: Please send us drawings in digs, dwg, step etc. together with detailed PDF.

If you have any requirements, please note, and we could provide professional advice for your reference.

Customer Inquiry →Engineering Communication →Cost Analysis →Sales Analysis →Quote to Customer

» 1-3 Work Days Only

» Submit RFQ with complete commercial terms

2.Q: What if we do not have drawing?

A: Samples would be available, and we would send you drawing to confirm.

Of course, we would ensure the safety of the drawing.

3. Q: How is the next ?

A: We will send the cost to you and get your confirmations for the quote;

4. Q: How to pay?

A: For small quantity, we could provide Paypal, Paypal commission will be added to the order.

For the big one, T/T is preferred.

5. Q: How to ship?

A: For small quantity, we have cooperation with TNT, FEDEX, UPS etc

For big quantity, air or sea would be available for you to choose.

5.Q: What about the packing details?

A: We attached our normal packing details.

If you have any special requirements, we would be willing to help.

Why choose us?

1. We have more than 10 years experience for production

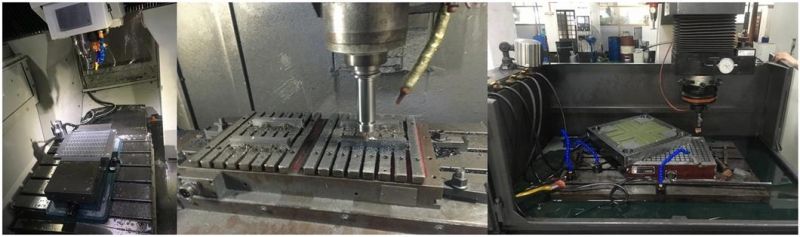

2. We have an extensive expertise in CNC machining, offer "One-stop Service".

3. Now we have more than 35 sets of various processing equipment. There are 15 people in professional technology, R&D team.

4. All of our operations are strictly compliant with ISO 9001: 2015 guidelines.

5. We have office in Germany as to offer better service to our clients.

Contact Info:

If you have any doubts, please do not hesitate to contact me.