Double Stack Mold for Pellet Mill

Shandong Kingoro Machinery Co., Ltd.- Using Hardness:>HRC45

- Surface Treatment:Heat Treatment

- Demoulding:Pull Core

- Material:Stainless Steel

- Application:Pellet Machine

- Average Wall Thickness:>3mm

Base Info

- Trademark:Kingoro

- Specification:Stainless Steel

- Transport Package:Wooden Case

- Diameter:6-12mm

- Condition:New

- Customized:Customized

- Certification:REACH, FCC, RoHs, CE

- Mould Life:>1,000,000 shots

- Model NO.:Ring Dies 6-12mm

- Origin:China

- HS Code:8436100000

- Production Capacity:1000,Month

Description

Basic Info.

Model NO. Ring Dies 6-12mm Mould Life >1,000,000 shots Certification REACH, FCC, RoHs, CE Customized Customized Condition New Diameter 6-12mm Transport Package Wooden Case Specification Stainless Steel Trademark Kingoro Origin China HS Code 8436100000 Production Capacity 1000/MonthProduct Description

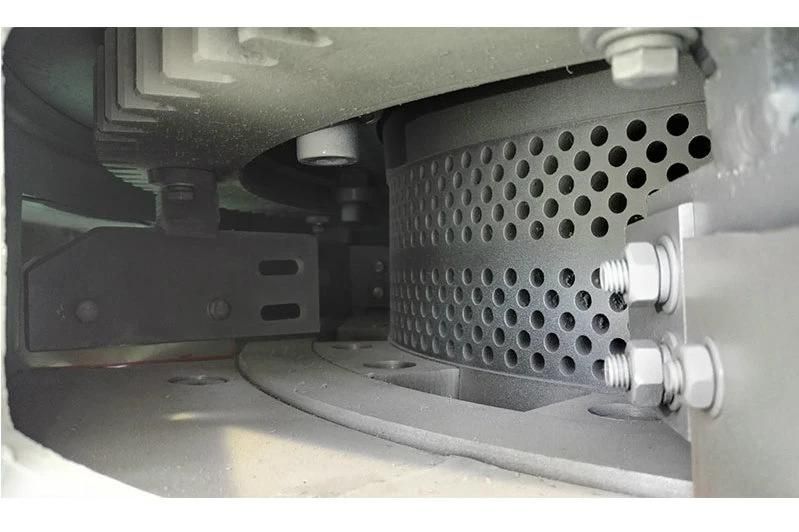

ApplicationRing die/Circular Mould is the key part of Ring Die Pellet Mill in the large scale pellet plant to produce animal feed, wood pellets, poultry feed,livestock feed,aqua feed, bio-mass pellet and other granules.

The quality of ring die plays an important role in making high quality pellets and high output,also can save much maintenance cost for pellet manufacturers.

Feature of our ring die:

1Made of imported high-carbon high-chromium stainless billet steel,optimization carbon,thus enhancing wearing and corrosion resistance and

hardness.

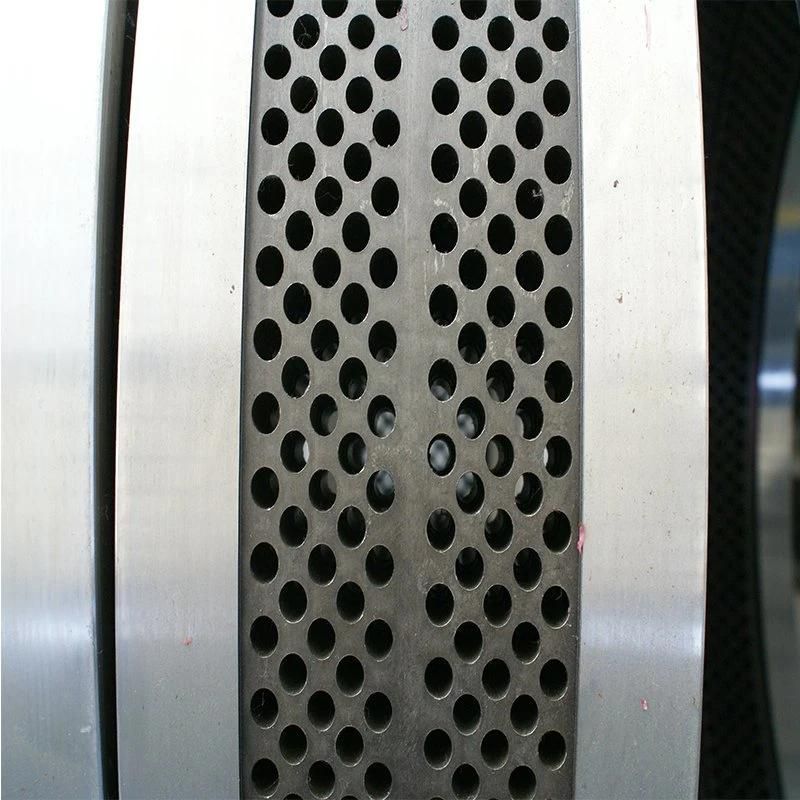

2 It can deal with all kinds of die hole over &1.2mm (&1.2mm included) and compression ratio.

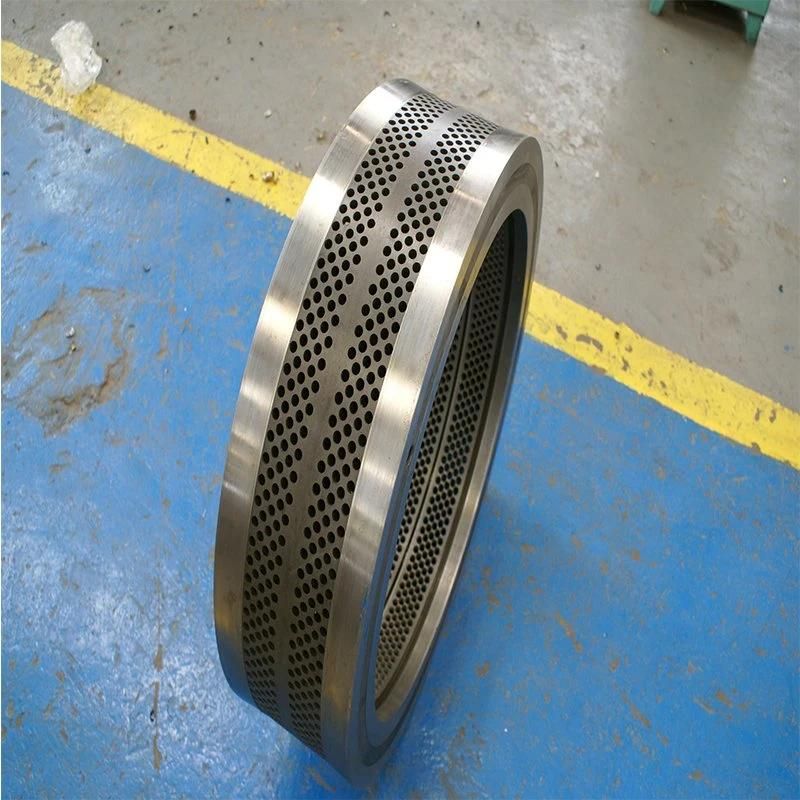

3Ring die can be produced up to 300mm-1500mm in diameter and 500mm in height.

4In ring die processing, full automatic control, one-time molding for die hole, high smoothness.

strong tensile strength,good wear resistance, good corrosion resistance,high wear resistance,long life

Advantage of our ring die:

1.Material refining technology,fewer impurities,high purity,largely reducing harmful elements content(such as

elements S,P ), thus comprehensive mechanical performance of material is raised.

2.Through roll forging, material is processed and strengthened and material fibre is complete and uniform,

which increases integrated mechanical performance of material.

3.Kingoro Company has the world advanced forging equipment and technology,electronic data processing

systems and perfect quality control system.

4.Ring die blank,generally chromiumalloy roll forgings, some factories use 45 ordinary carbon steel.

5.Hardness of blank must be controlled, ranging from HB170 to HB220.If the hardness is too high,the drill is

easy to break and happens with die hole when drilling. If hardness is too low, the surface finish of die hole

will be not good.

6.In order to control blank inner material uniformity, every blank must be carried out with fault detection,

which can avoid defects such as flaw, pore-free,crackle and inclusions etc.

7.After machining and heat treatment process, hardness of ring die can be up to HRC 52-58(inner diameter less than 350mm),HRC50-56(inner diameter more than 350mm),more wearable and

anti-corrosion.

8.In order to control hardness uniformity of ring die after heat treatment, we choose more than three points

in each part of trisection of peripheral direction to test hardness and take average.The difference of

hardness value between each part should not be higher than HRC4.

9.According to the principle of metal material science combined with gas quenching and C,Cr,Mn,Ni,V

elements content is optimized, forming the standard of ring die.

Introduction of pellet machine ring die

1. Material of the ring die: X46Cr13 /4Cr13(stainless steel)

2. Hardness of ring dies: 52-60 HRC

3. Diameter of ring die can do: 1.0mm up to 28mm

4. Pellet die type can do: Ring Die or Flat Die

5. Outer diameter can do: Outer diameter up to 1800mm

6. Pellet Die model we can customize

Costomer Visit

Workshop Photo