High Precision Mould Company Injection Moulding Plastic Mold Making for Components Tool

Dongguan Ace Plastic Hardware Products Co., Ltd.- Injection System:Hot Runner ,Cold Runner

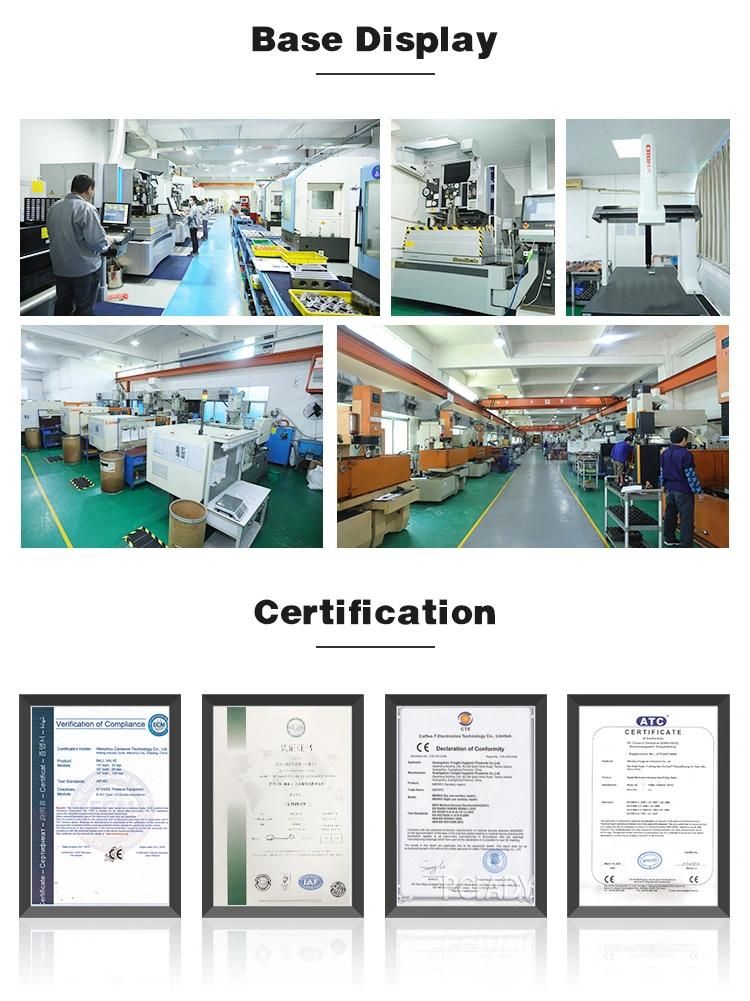

- Certification:CE, ISO9001

- Application:Electronic, Hardware, Machinery, Household Applicances, Car

- Material:Stainless Steel

- Type:Plastic Mould Parts

- Cavitation:Single ,Mutil Cavites

Base Info

- Specification:Steel

- Transport Package:Standard or as You Request

- Standard Parts/Cylinders:Dme,Hasco,Progressive,Misumi,Parker,HP,Merkle

- Standard Delivery:40 Days or 5 Weeks

- Cooling:Baffles,Sprin Piple,3D Printing Water Line

- Steel Standard:Assab,Finkl,Bohler, Groditz,Buderus

- Ejector System:Pin,Air Valve,Stripper Plate

- Trademark:ACE

- Origin:Guangdong China

- Production Capacity:2000set,Sets Per Month

Description

idea

We offer low to high volume plastic injection production. Our injection press size ranges from 50 to 1300 ton machine.

Below is the industry / market we serve:

* Automotive

* Household appliance

* Engineering / electronics

* Medical

* Cosmetics

Our Services

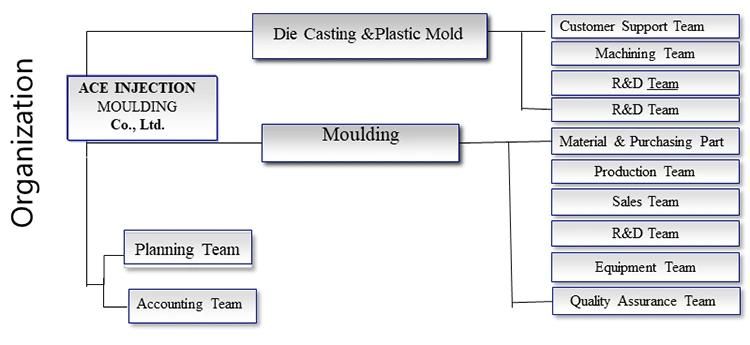

ACE Molding Group is a privately owned company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception.Is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards.Our team of CAD designers will ensure that your imagination is incorporated into the actual product!If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!Our products include :

*Custom Plastic Injection Parts

*Multi-cavity plastic parts

*High Precision Molds

*Insert & over molding

*Double Short Molding

*Unscrewing Molding

*Gas-assisted Molding

*Die Casting Molding

*Prototype plastic parts and Low cycle plastic parts molding

*Gas Assist molding

*Elastomeric molding

*IML & IMD part production

*Thin wall plastic molding

*High temperature molding

*Foam Injection molding

Why Choose Us

1. We have our own design and development team and factory, with more than 14 years of product production experience. Familiar with and good at developing business with overseas market.

2. We can provide OEM/ODM services for all kinds of customers, and our professional support team will provide services for customers 24 hours a day.

3. We have a very strong quality control system to ensure the best quality of our products, the best service and competitive price.

4. Samples are always available for quality inspection and can be sent to you very quickly.

5. Design ability: design according to customer requirements.

6. We deliver goods on time and cooperate with customers sincerely.

*8 project engineers*6 Sales people*5 full-time quality inspection personnel *4 people in logistic team

*60 tool makers*13 Office worker

Workshop

Our factory is under ISO standards & certification.This insures productivity and total control on quality.

Packaging &Shipping

Our standard packaging for plastic injection parts we use PP bag plus cardboard boxes or as per customer requirements.Our standard packaging for plastic injection mold is wooden pallets or wooden cases.

How To Order

Kindly contact or email us your inquiries or RFQs. One of our sales team would contact you asap and offer professional consultation on all your plastic molding needs and provide the best price that is suitable to your requirements.

F A Q

Q: What services do you provide?A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?A: You can send us an inquiry via email, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don't have part drawings?A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How do you deliver the goods?A: We have our own logistics department that could provide shipping costs via Sea or Air freight, Incoterms EXW, FOB, DDP, DDU etc. Or we can work with your appointed shipping forwarder.

Q: How can I guarantee our quality?A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

CONTACT US