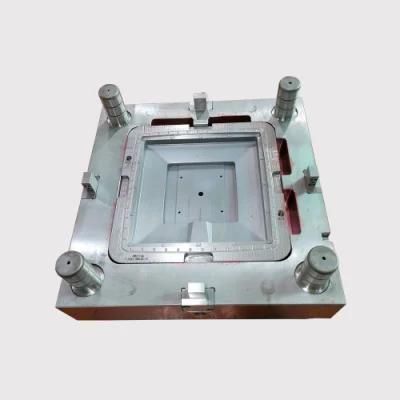

Hasco Multi Cavity Injection Molding 500, 000 Shots Plastics Injection Tooling

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Car, Furniture, Electronic, Hardware

Base Info

- Lead Time to T1 Sample:4~5 Weeks

- Normal Plastic:POM,PP,PPE,PS,PVC,SA...

- Surface:Textured,Glossy or Mirror Polished,Printing,etc

- Mold Life Time:300K~1000K Cycles According to Your Requests

- Mold Cavity:Single Cavity , Family Molds , Multi Cavity

- Design Sofeware:Ug,Proe,CAD,Solidwork,etc

- Name:Plastic Injection Molding for Housing

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Hot Runner

- Model NO.:HW-1138

- Lead-Time for Production:1~2 Weeks

- Transport Package:Wooden Cases,Air,Sea

- Specification:Custom

- Trademark:HOWE or Custom

- Origin:China

- HS Code:84807100

- Production Capacity:40sets,Month

Description

Howe mold mainly specialize in doing plastic injection mold with trial and series inside by 100~1000 ton, with abundant experience in export mold & injection field more than 11 years.

Our company is professional on plastic injection mould,blowing mould & plastic products.

Car parts moulds: Car bumpers, head lamp, tail lamp

Industrial moulds: Outdoor dustbin, Indoor dustbin, logistic pallet,pipe fitting,cable tie etc.

Household moulds: table,chair,stool,storage,baskets, crates, kitchenware etc.

Appliance moulds: Washing machine, TV frame, Fan, Cooling machine etc.

Plastic Products: Outdoor Dustbin, Indoor dustebin, Storages etc.

Mould Trade Process

Mould Trade Process1.R&D Customers provide the 3D drawings or samples to us

2.Negotiation Mutual discuss for the materials ,the price ,delivery time etc

3.Place the order Strictly do according to the order to meet our customer needs

4.Mould Design confirmation by our customer-Mold making strictly by the design

5.Sample Trial sample-our customer confirm-move forward to batch production

6.Delivery Delivery could according to our customers required by sea