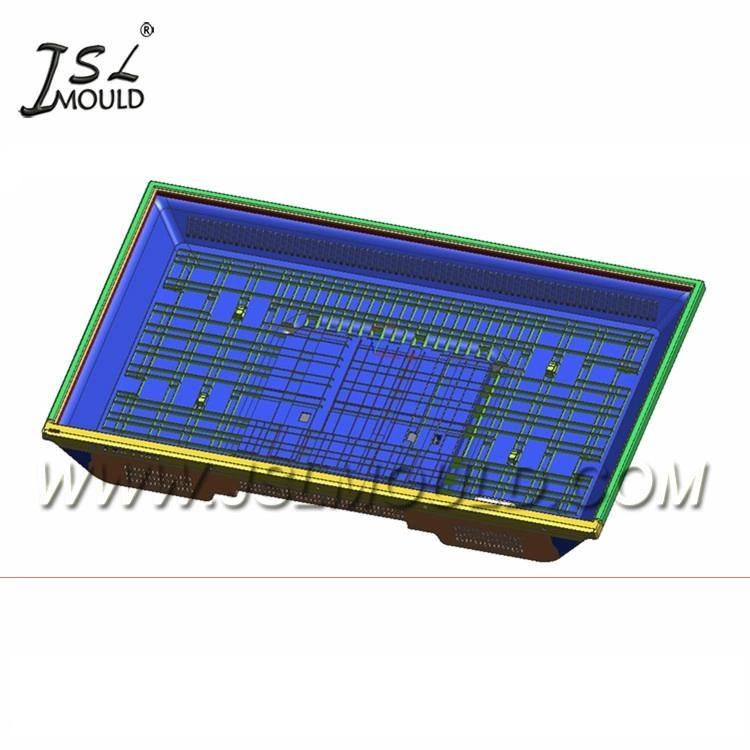

High Quality Plastic LED TV Back Cover Mold

Taizhou City Huangyan Beiwei Mould Industry Co., Ltd.- Plastic Material:ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:1 Year

- Process Combination Type:Single-Process Mode

Base Info

- Heat Treatment:Nitriding, etc

- Mould Base:S50c,Lkm,Hasco

- Mould Operating Mode:Automatically by CNC

- Mould Cooling System:by Experienced Designer

- Mould Design Software:Ug, Proe, Solidworks CAD, Ect

- Mould Standard:Dme, Hasco, Lkm, etc

- Mould Runner System:Hot or Cold Runner System

- Mould Quality Control:Professional QC

- Size:According to Customers Requirement

- After-sales Service:2 Years

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Application:Household Appliances, Commodity, Electronic

- Model NO.:J18103113

- Transport Package:High Qulity Wooden Case

- Specification:DME, HASCO, LKM, etc

- Trademark:JSLMOULD

- Origin:Huangyan, Taizhou, China

- HS Code:8480719090

- Production Capacity:500sets,Year

Description

JSL Mould Quality Control

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking(Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- checking each part of mould's size after machining, according to 2D drawing

- mould testing(check mould running condition)

3. Check with customer's requirement again before mould shipping.