Precision Deep Drawing Progressive Die for Compressor Cover

Zhongshan Huihai Mold & Automatic Equipment Co., Ltd.- Processing Method:Punching and Shearing Mould

- Material:Carbon Tool Steel

- Application:Household Appliances, Hardware, Home Use

- Technics:Drawing Die

- Process Combination:Single-Process Mould

- Manufacturing Technology:Computer Technology

Base Info

- Stamping Material:Stainless Steel, Aluminum Alloy, Brass, Copper etc

- Design Software:Auto CAD, Cae, PRO-E, Solidworks, Ug etc

- Standard:Misumi Dayton

- Model No:Hh069

- Customized:Customized

- Packing:Wooden Case

- Lead Time:50 Days

- Parts Detection Method:Measurement of Three Axis NC

- Milling Speed:Normal Speed

- Mold Cavity Technology:CNC Milling

- Driving Motor Type:Permanent Magnet

- Model NO.:HH455

- Transport Package:Wooden Case

- Specification:SGS, ISO

- Trademark:huihai auto

- Origin:Zhongshan

- HS Code:8207209000

- Production Capacity:350 Sets ,Year

Description

Basic Info.

Model NO. HH455 Driving Motor Type Permanent Magnet Mold Cavity Technology CNC Milling Milling Speed Normal Speed Parts Detection Method Measurement of Three Axis NC Lead Time 50 Days Packing Wooden Case Customized Customized Model No Hh069 Standard Misumi Dayton Design Software Auto CAD, Cae, PRO-E, Solidworks, Ug etc Stamping Material Stainless Steel, Aluminum Alloy, Brass, Copper etc Transport Package Wooden Case Specification SGS, ISO Trademark huihai auto Origin Zhongshan HS Code 8207209000 Production Capacity 350 Sets /YearProduct Description

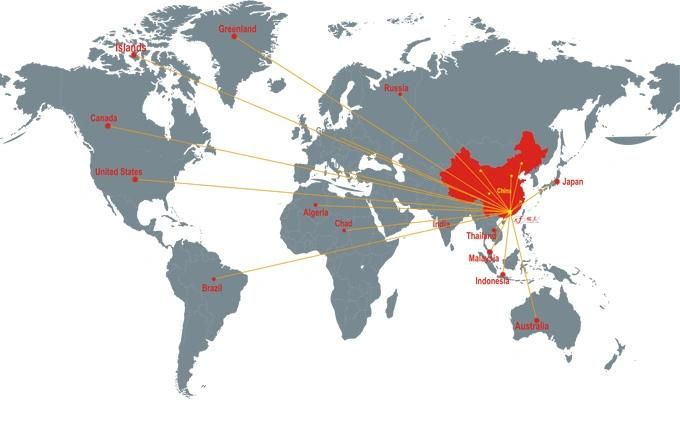

Huihai specializes in manufacturing and supplying of various moulds and dies, such as metal stamping dies, plastic injection moulds, motor stator&rotor molds and stamping parts and injection parts since 2005.Huihai provides various molds & dies to the clients from USA, Spain, Italy, Russia and so on.

"Good quality with cost-effective" is the base of Huihai business. Huihai people keep creating value for customers as our mission.

ISO 9001: 2008 certificated.

Our Advantages:

1. Competitive price

2. Strict quality control system (ISO9001 system manage)

3. Quick mold making and delivery (4-7weeks)

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers

Special info.:

Customized design according to customer part design or sample.

Mold base: Standard mould base or customized

Inserts(cavity and core): Cr12mov, SKD11, D2, M2, DC 53, SKH-9, Copper alloy or the material you required.

Standard parts: MISUMI, PUNCH, DAYTON, DANLY (Japan or Europe US)

Part material: SPCC, SPCE, SPCD, DC01, DC04, Stainless steel 304.430.316, Aluminum alloy, and so on

Lead time of first samples: Around 4~7weeks.

Processing Equipments

| Machine Equipment | QTY | Tapping center | 1 |

| CNC | 5 | Plate shears | 1 |

| WEDM | 2 | Mechanical Press | 13 |

| WEDM-HS | 2 | Hydraulic Press | 2 |

| EDM | 3 | Inspection Equipment | Qty |

| Radial drill | 8 | CMM | 1 |

| Sawing machine | 1 | projector | 1 |

| Grinding machine | 4 | Rockwell-hardness-tester | 1 |

| Milling machine | 2 | Dial Calipers(0-300mm) | 8 |

| Bench drill | 4 | Slide Calipers(0-1000) | 6 |

| lathe | 2 | Pound scale | 1 |

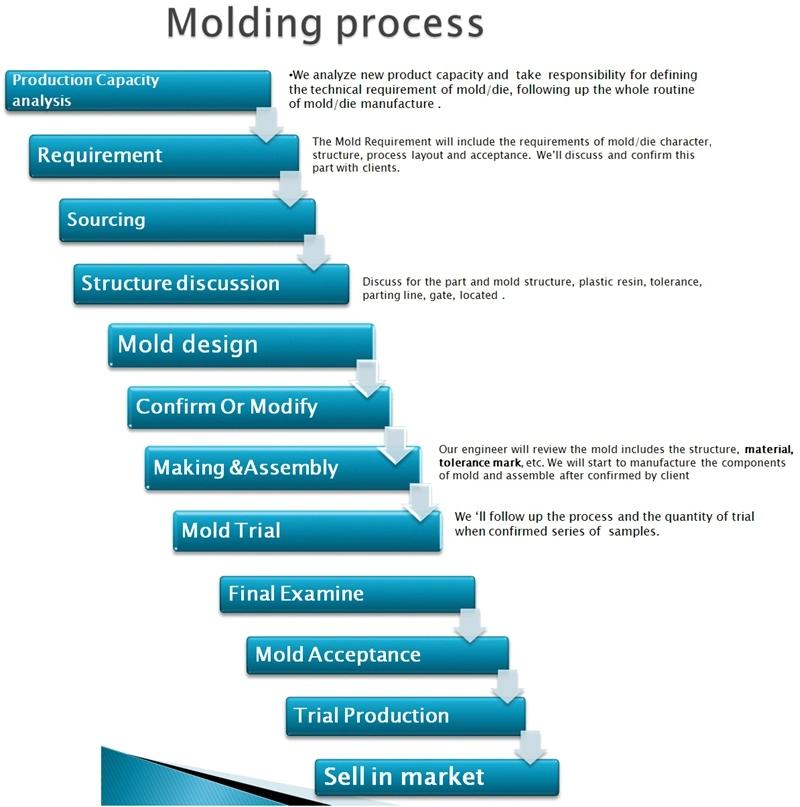

Project process layout

To control the production time, and to decline the probability of clam & return from the end users, making a accurate mold is very important start , we have completed molding produced process to fulfill the needs of client.

Time Control

- Understanding and controlling the factors of any mold making process is the key to fulfill project control, we use computer analysis and specialized division to take care of controlling mold component unit and predicting work hour.

- The Parts we'll take into consideration

WELCOME TO ENQUIRE AND TAKE MORE...