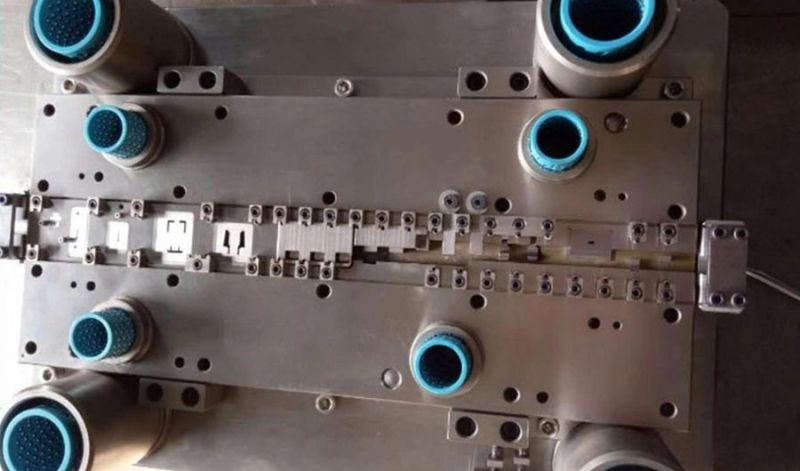

High Quality Tungsten Carbide Plates for Molds

Zhuzhou Eastern Carbide Co., Ltd.- Processing Method:Punching and Shearing Mould

- Material:Tungsten Carbide

Base Info

- Specification:WC+Co Powder

- Transport Package:Standard Packing for Export

- Logo:Laser Mark Available

- Dimensions Range:W 5~300 mm X L 5~700 mm X T 5~700 mm

- Main Using Purpose:Metal Machining and Wear Parts

- Surface Finishing:Polished and Unpolished

- Grades:K10,K20,K30,K40,Yl10.2,Yg6,Yg6X,Yg8,Yg10X,Yl10.2

- Grain Sizes Selection:Ultra Fine, Fine, Medium, Coarse

- Cobalt Percentage:From 3% to 30% Based on Different Grades

- Wc+Co Powder:100% Virgin Material

- Manufacturing Technology:by Molding

- Technics:Punching Die

- Model NO.:carbide plates

- Trademark:None

- Origin:Zhuzhou City, Hunan, China

- HS Code:8209009000

- Production Capacity:1000 Tons

- Package size per unit product:34.00cm * 24.00cm * 17.00cm

- Gross weight per unit product:25.000kg

Description

(ISO3738)

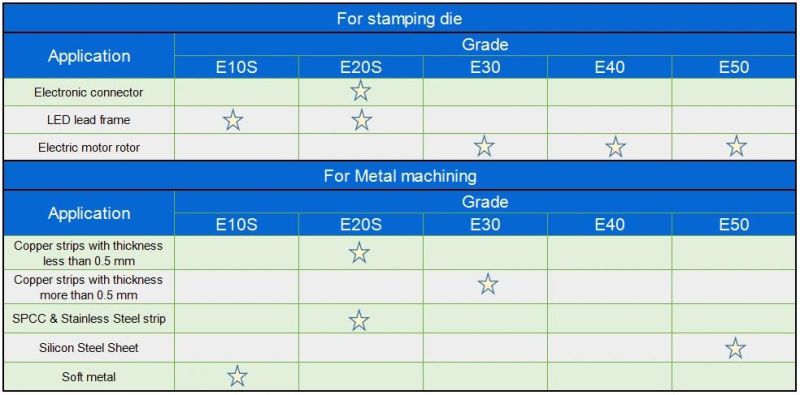

Application

Main used as mold material, wear parts and protection parts in different designs and dimensions, normally fixed by brazing process or fastening.

Main used as mold material, wear parts and protection parts in different designs and dimensions, normally fixed by brazing process or fastening.High hardness with suitable bending strength will provide very long tool life for the carbide parts, can save your costs and time for production.

About us

Quality Control System: We always follow the high quality standard for production, from the material preparing to final product ready, all product will go through 3 inspections before we send them to you. Our professional teams will take care of your product and ensure the good and stable quality for all batches.

Our regular product is tungsten carbide tips, carbide inserts, end mills,carbide saw tips,carbide mining parts, carbide rods, plates and stripes.

We also have rich experience for customized product, we make your designs become real product, which perfectly match your need. We have many successful projects on the for our clients in different countries.

Packing:

A. Standard packing

-Plastic boxes with foam inside and carton outside.

-Paper boxes with foam inside and carton outside.

-Inner boxes/packing material inside and plywood box outside (for heavy product).

B. Customized packing available: We can do special packing based on client's requirements.

FAQQ. Are you manufacturer or trading company ?

A. We are the manufacturer with our own workshop and production teams.

Q. How to ensure the good quality from you?

All product will go through inspection at least by 3 times:

Material checking: Use the same batch of material, to make carbide pieces to test the compositions and mechanical properties, like density, hardness, bending strength, Cobalt Magnetism, etc.

Semi product checking: Main checking the

Final product checking: Check all data and compare to the target sample we made.

Also check all dimensions and surface finishing.

Q:How long is the delivery time?

For standard product, within 15days

For customized product, within 22 days

Q:Is your product customized or standard?

A: We have the regular product and also have rich experience for customized parts.

We have many success projects that make the product based on your own designs.

Q:What are the payment terms?

Regular payment term: 30% deposit and balance paid before delivery

Other options:

Full payment before delivery

Full payment after receiving the goods

O/A 30 days