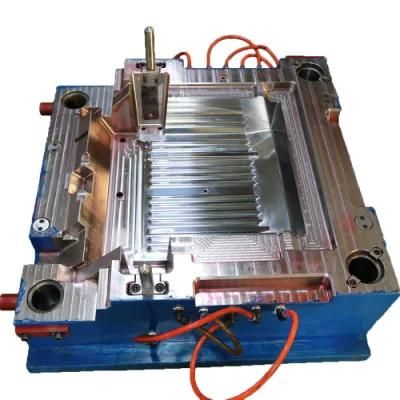

Customized Tooling Silicone Stamping Plastic Injection Molding for Chair/Cap/Toy/Auto ...

Qingdao Chuangyu Precision Machinery Co., Ltd.- Surface Finish Process:Anodizing

- Mould Cavity:Custom Cavity

Base Info

- Transport Package:with PE Plastic Packed Then Into The Wooden Box

- Logo Method:Laser Engraving, CNC Engraving, Scree

- Surface Treatment:Anodizing, Powder Coating, Painting etc

- OEM/ODM:Yes

- Port:Qingdao Port

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Hot Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:HDPE

- Model NO.:CM01

- Specification:up to design

- Trademark:Chuangyu

- Origin:China

- HS Code:8480419000

- Production Capacity:20pieces,Month

- Package size per unit product:15.00cm * 4.50cm * 1.40cm

- Gross weight per unit product:0.550kg

Description

1. Basic Information

Mold type: All tyes of produts plastic mould

Mould base material: #45. LKM, LYM standard etc

Mould spare parts material: Jinghong, HASCO, DME etc

Hardness of steel: 28-55HRC

Mould design: 3D/2D drawings

Runner: Cold runner

Design days: 1-3days

Mould life: 500, 000-3, 000, 000 shots

Plastic material: PE, PC, PS, PP, PA, ABS, etc

Injection system: Pin point gate

2. Quality Reference

Level A: 1, 000, 000 shots - high

Level B: 800, 000 shots - middle

Level C: 500, 000 shots - normal 3. Application

Communication/Electronic/Auto parts/Surveillance products/Medical device/equipment and so on4. Customers assistance for initial detailed quotation on plastic injection molding

1) 2D/3D Design drawings offered

2) If there is no drawing, please advise the dimension/photos with dimension

3) Material information

4) Level and quantity information if possible.

FAQ:

1. Q: What is the processing for the quote?

A: We can quote from your 3D formats like IGS, STP, PARASOLID etc and 2D drawings as well; Quote the price to clients after got the 2D or 3D drawings within 2 hours;

2. Q: How is the next?

A: We will send the cost to you and get your confirmations for the quote;

3. Q: What is the software will you use for the proceeding?

A: We make the 3D programm with PRO-Engineer, UGS, SOLIDWORKS, MASTERCAM etc;

4. Q: What is the type of machines for manufacturing?

A: Manufactured from CNC Machining, Laser cutting, stamping, injection as well as the parts files different;

5. Q: Do you do the surface treatments please?

A: Yes, sure. We do the surface treatments, for instance: Chromated, powder coating, Anodizing, laser etching as well as painting;

6. Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping;

Why choose us?

1. We have more than 10 years experience for production

2. We have an extensive expertise in CNC machining, offer "One-stop Service".

3. Now we have more than 35 sets of various processing equipment. There are 15 people in professional technology, R&D team.

4. All of our operations are strictly compliant with ISO 9001: 2015 guidelines.

5. One of our staff is settled down in Germany as to offer better service to our clients.