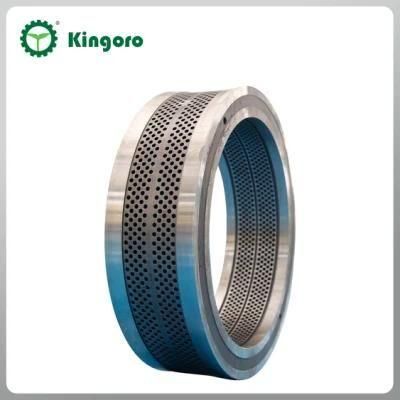

High Cost-Effective Pellet Ring Dies

Shandong Kingoro Machinery Co., Ltd.- Using Hardness:>HRC45

- Surface Treatment:Heat Treatment

- Demoulding:Pull Core

- Material:Stainless Steel

- Application:Pellet Machine

- Average Wall Thickness:>3mm

Base Info

- Trademark:Kingoro

- Specification:Stainless Steel

- Transport Package:Wooden Case

- Diameter:6-12mm

- Condition:New

- Customized:Customized

- Certification:REACH, FCC, RoHs, CE

- Mould Life:>1,000,000 shots

- Model NO.:Ring Dies 6-12mm

- Origin:China

- HS Code:8436100000

- Production Capacity:1000,Month

Description

Basic Info.

Model NO. Ring Dies 6-12mm Mould Life >1,000,000 shots Certification REACH, FCC, RoHs, CE Customized Customized Condition New Diameter 6-12mm Transport Package Wooden Case Specification Stainless Steel Trademark Kingoro Origin China HS Code 8436100000 Production Capacity 1000/MonthProduct Description

ApplicationRing die/Circular Mould is the key part of Ring Die Pellet Mill in the large scale pellet plant to produce animal feed, wood pellets, poultry feed,livestock feed,aqua feed, bio-mass pellet and other granules.

The quality of ring die plays an important role in making high quality pellets and high output,also can save much maintenance cost for pellet manufacturers.

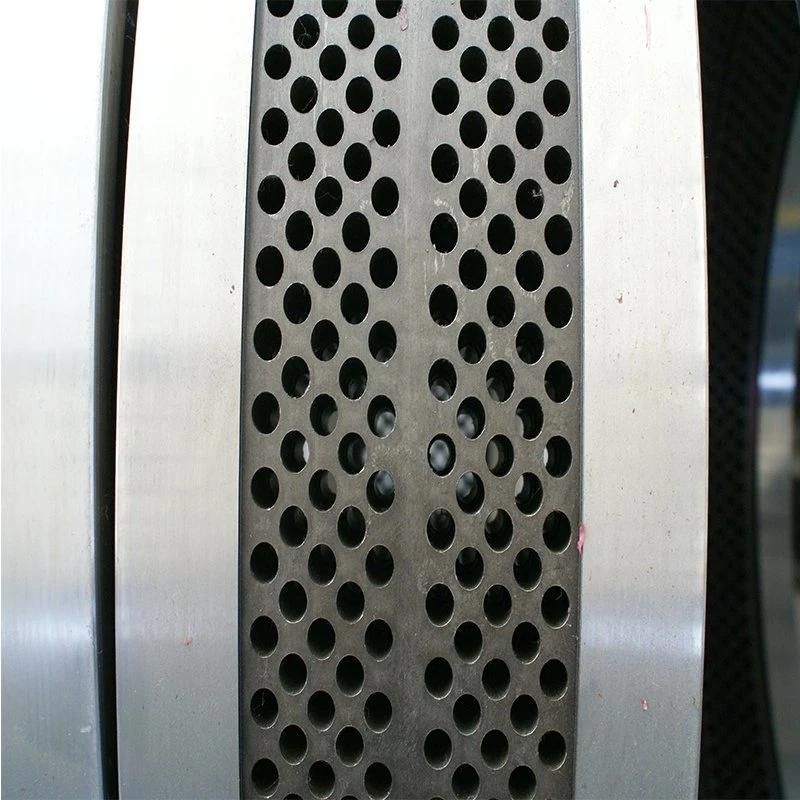

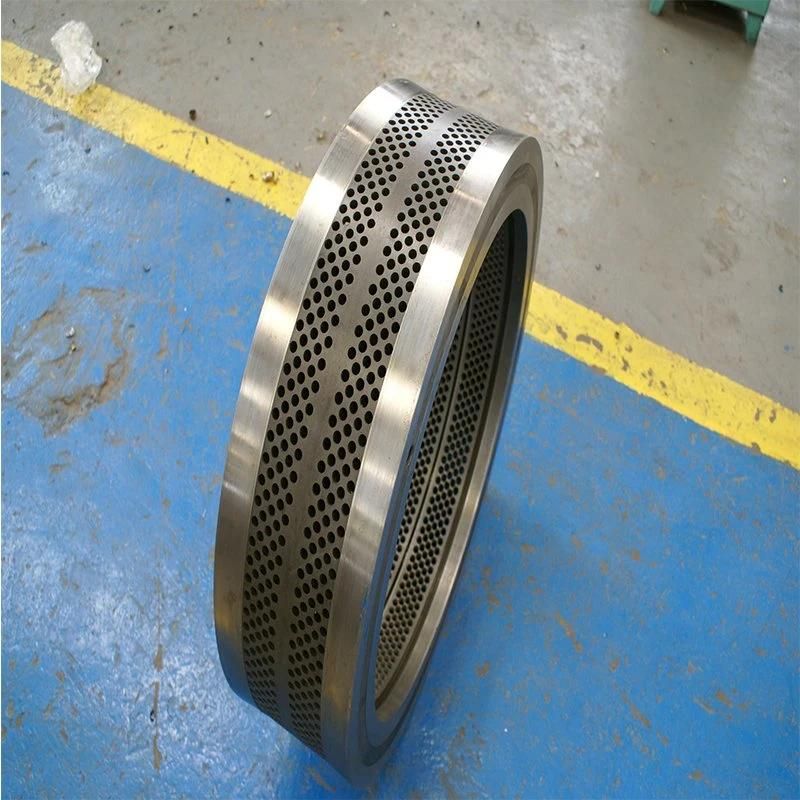

Introduction of pellet machine ring die

1. Material of the ring die: X46Cr13 /4Cr13(stainless steel)

2. Hardness of ring dies: 52-60 HRC

3. Diameter of ring die can do: 1.0mm up to 28mm

4. Pellet die type can do: Ring Die or Flat Die

5. Outer diameter can do: Outer diameter up to 1800mm

6. Pellet Die model we can customize

Costomer Visit

Workshop Photo