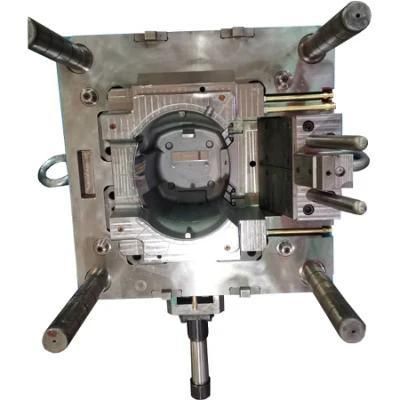

Lkm Injection Mold for Electronic Plastic Shell Parts

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Export Country:Janpan, Europe, USA, Mexico, Australia, etc

- Advantages:10 Years Experience

- Shipping:by Sea or by Air as Customer Requirement

- Packaging Details:Wood Box

- Color:OEM

- Quotation:According to Samples, Drawing and Specific Require

- Product Name:Plastic Injection Mold for Plastic Shell

- Mould Material:45#, 50#, P20, 738, 738h, 718, 718h, Nak80, 2316

- Customized:Customized

- Standard:PUNCH

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Runner:Cold Runner

- Model NO.:XH20201110-1

- Mould Life:500, 000-1, 000, 000 Shots Guarantee

- Mould Lead Time:3~4weeks

- Transport Package:Hard Carton, or Customized

- Specification:According to your drawing

- Trademark:OEM

- Origin:Guangdong, China

- HS Code:8480719090

- Production Capacity:40sets,Month

Description

Basic Info.

Model NO. XH20201110-1 Runner Cold Runner Design Software UG Installation Fixed Certification ISO Standard PUNCH Customized Customized Mould Material 45#, 50#, P20, 738, 738h, 718, 718h, Nak80, 2316 Product Name Plastic Injection Mold for Plastic Shell Color OEM Quotation According to Samples, Drawing and Specific Require Packaging Details Wood Box Shipping by Sea or by Air as Customer Requirement Advantages 10 Years Experience Export Country Janpan, Europe, USA, Mexico, Australia, etc Mould Life 500, 000-1, 000, 000 Shots Guarantee Mould Lead Time 3~4weeks Transport Package Hard Carton, or Customized Specification According to your drawing Trademark OEM Origin Guangdong, China HS Code 8480719090 Production Capacity 40sets/MonthProduct Description

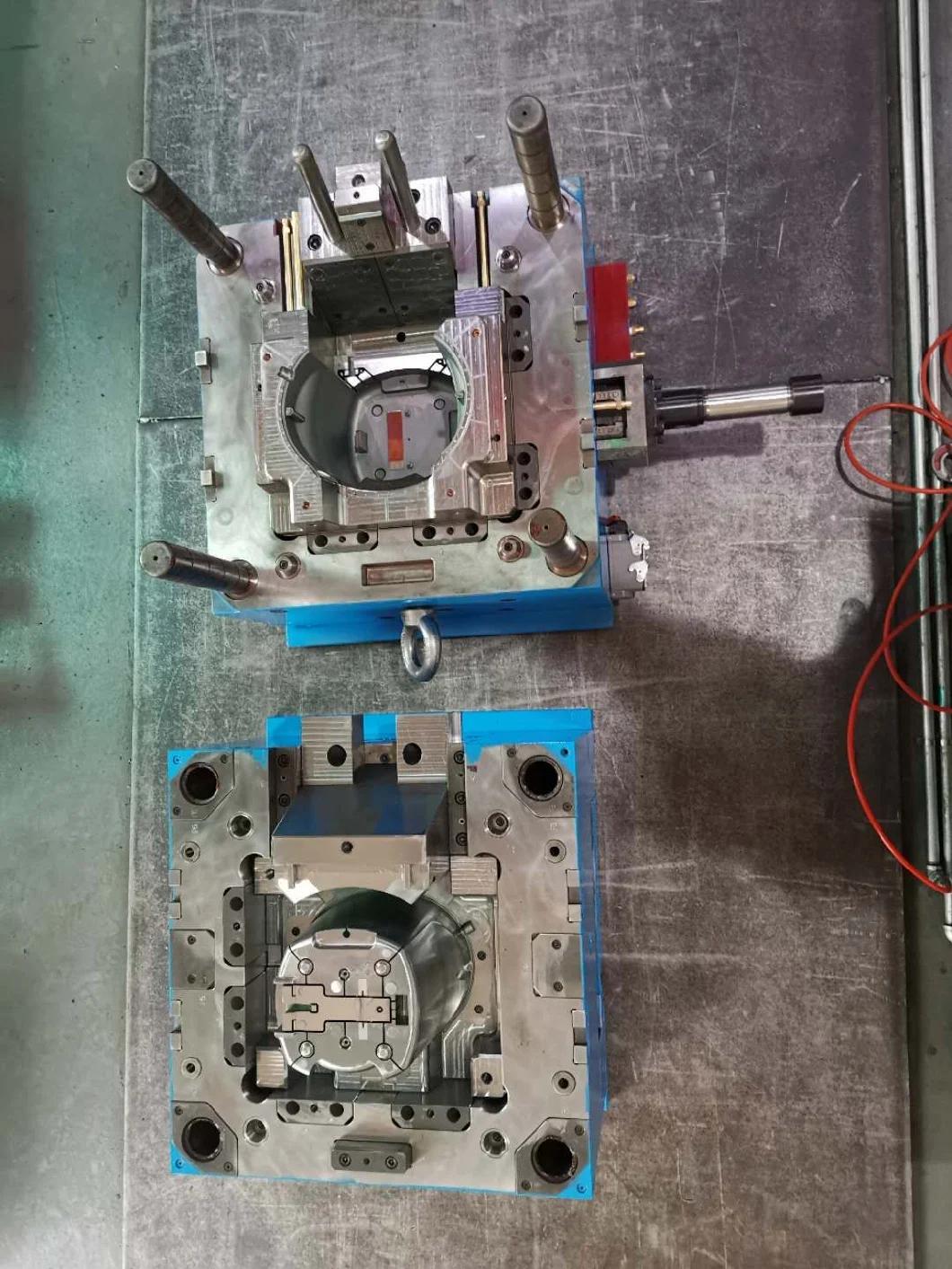

LKM Electronic Plastic Shell Parts moulding Electronic Appiliance Plastic MoldHigh-quality rapid custom prototyping and manufacturing services for product development. Please advise your product design information for a competitive injection molding quote today.

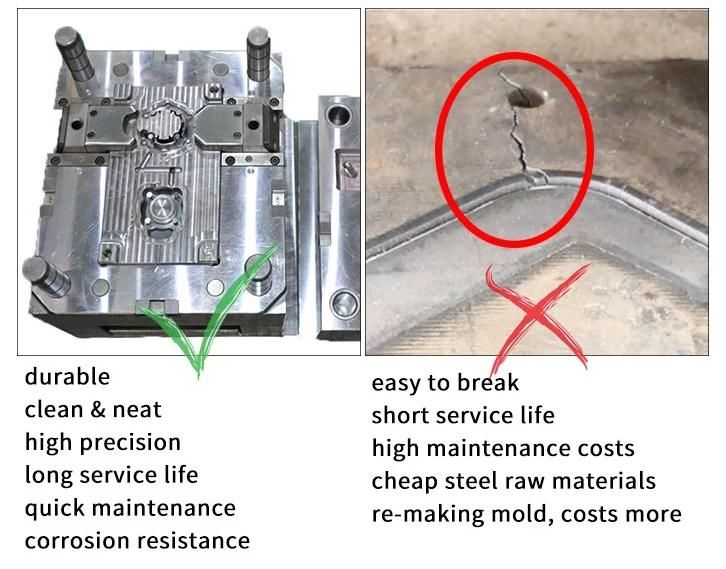

Our Mould is on the Left as following:

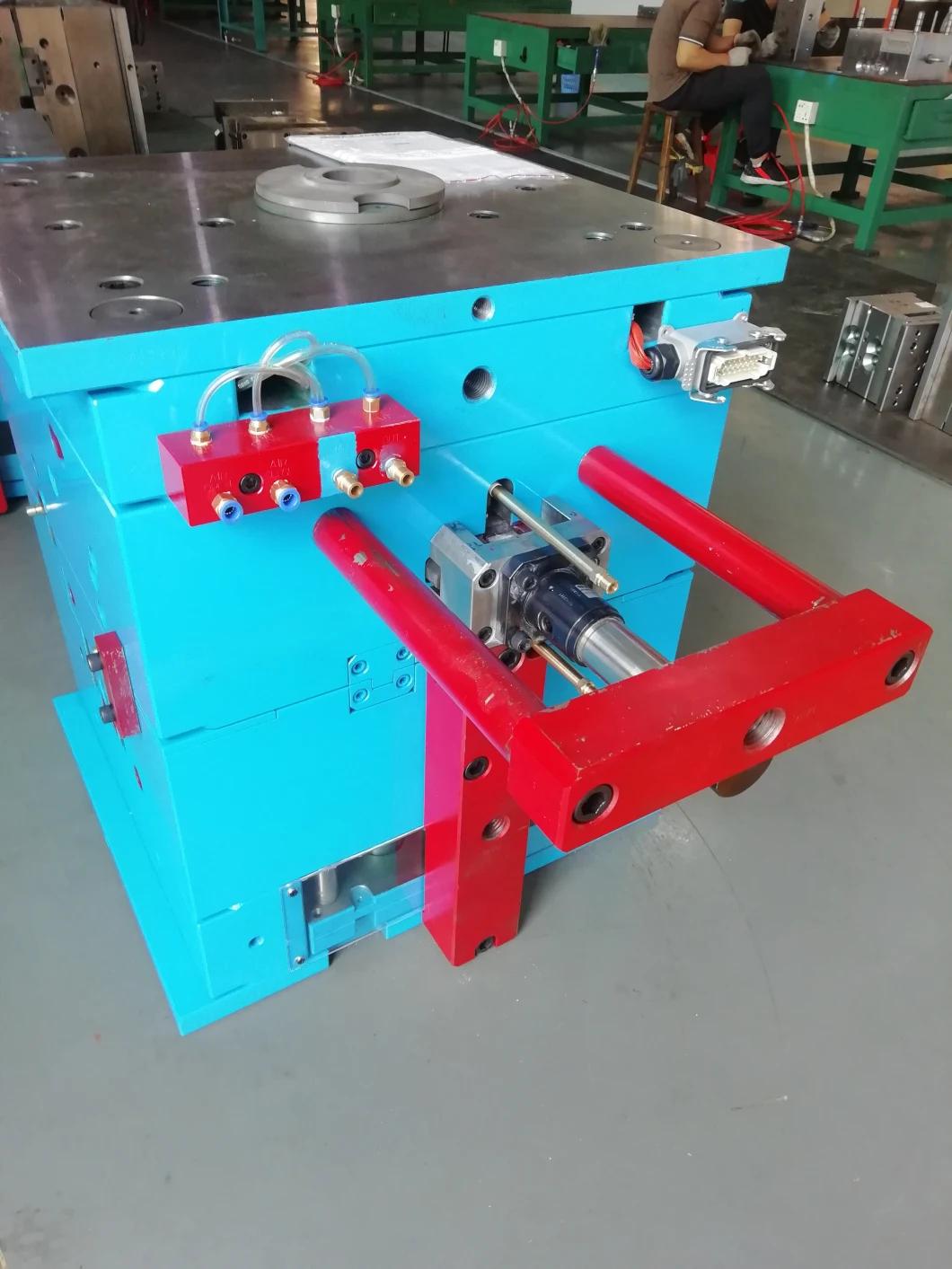

Manufacturer Profile Howe Precision Mold Co. is a qualified engineering and manufacturing company that designs and makes production tools of high-quality injection mold and die-cast mold for plastics molding and metal casting in wide ranges of automotive, household appliances, consumer goods, etc., with an engineering team over 10 average years of experience. Established in Dongguan City China, by the general manager Mr. Shawn Lee with the technical backgrounds.

Committed to providing one-stop services from prototyping through toolings to high-volume product production with competitive price and short lead time based on advanced technologies, scientific management and continuous improvement.

Our Workshop

Family Culture:

Customer Visiting:

Advantage:

1. We are a manufacturer specialized in OEM injection plastic parts from design to rapid prototype to mold to mass production for more than 13 years.

2. Long term cooperation with some Top Brand Auto Industry, such as Volvo and SKODA.

3. We can assemble a complicated products. Providing samples with important dimensions and customizing inspection report material certification to customers for validation and verification.

4. Equipment includes CNC, EDM, grinding machine, injection machine (from 45ton to 1000ton), we can supply high precision and complex injection molds and products .

5. We offer unique solutions to your products at a competitive price and best service.

6. Strict quality control. The factory has the most advanced testing equipment to ensure the precision of the mold.

7. Your products will enter the supermarket, we can design a package for you.

8. Quick mold making and on-time delivery.

9. We accept small order quantity, look forward to receiving your inquiry.

10. Excellent R&D teams, Professional technicians and rich experienced workers

11. Providing good After-sale service, if the products have any quality problems, we will take charge of it.

Packing:

FAQ :

* Are you factory or trading company?

HOWE is a plastic mold factory in Dongguan, China, welcome to visit us.

* Is HOWE an ISO registered company?

Yes, GBM is an ISO 9001:2015 certified mold manufacturer, we take pride in our constantly improving process and always try to add

value for customers with the best efforts.

* What type of tooling services do you offer?

HOWE can help you manufacture, assemble and printing for your plastic parts. Besides normal molding process, HOWE has deep expertise of 2-shots molding, over-moulding and vertical insert molding.

* Do you have in-house mold design?

Yes, we have our own design team, our engineering manager has over 10 years' experience.

* How long it takes to design my mold?

The mold design timeline is dependent upon the complexity of the project. A simple construction mold can be designed in 1 or 2 days, while a complex mold can take several weeks. HOWE designers and project manager will work closely with you to design your mold in prefessional and efficient manner.