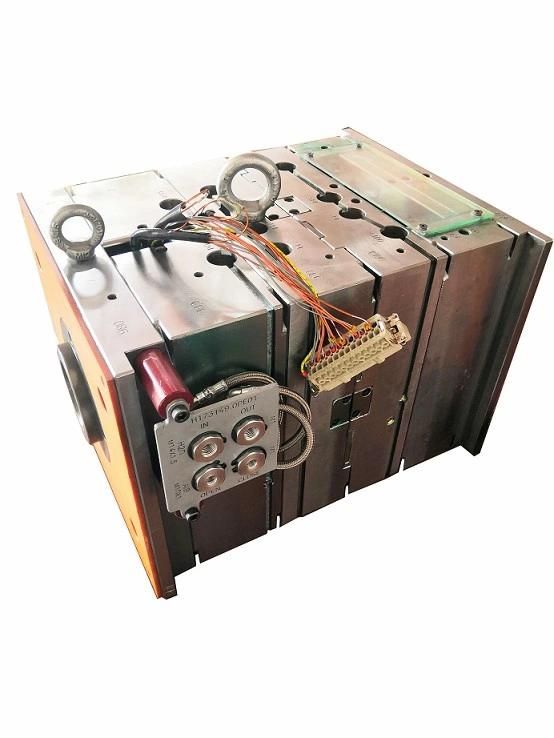

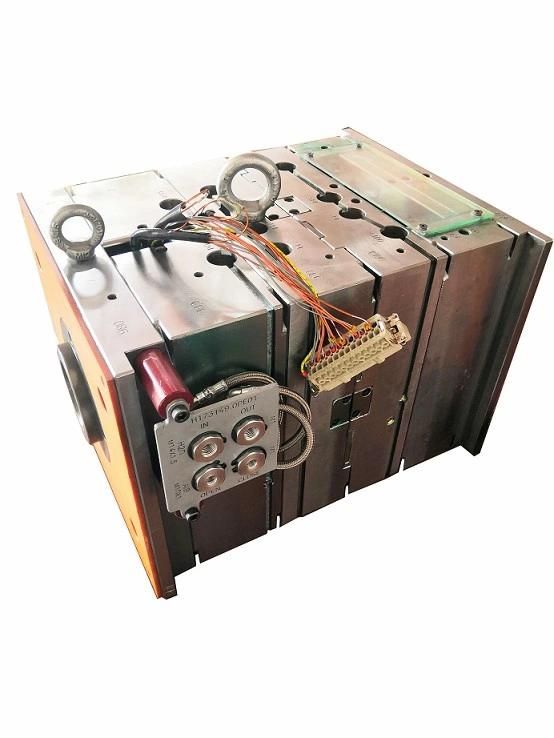

PC PMMA Auto Lamp Cover Car Headlights Plastic Injection Mold

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:PC

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Mirror Polishing

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Specification:According to customers′ drawings

- Transport Package:Export Standard Wooden Case for Mold

- Customized:Customized

- Standard:Hasco,Dme

- Certification:ISO

- Installation:Semi Fixed

- Design Software:Ug, PRO-E, Autocad

- Runner:Hot Runner or Cold Runner

- Model NO.:HW-201007-1

- Trademark:HOWE,OEM

- Origin:Dongguan, China

- HS Code:8480719090

- Production Capacity:300-400 Sets,Year

Description

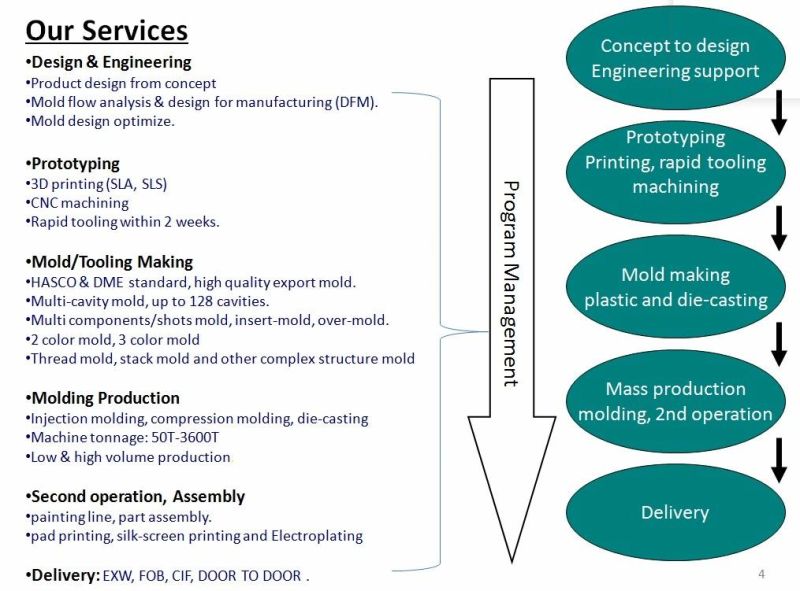

Sodick, Seiki, CNC, high-speed carve, EDM, wire cut, drill

Process of mold making

Quality assurance and service:

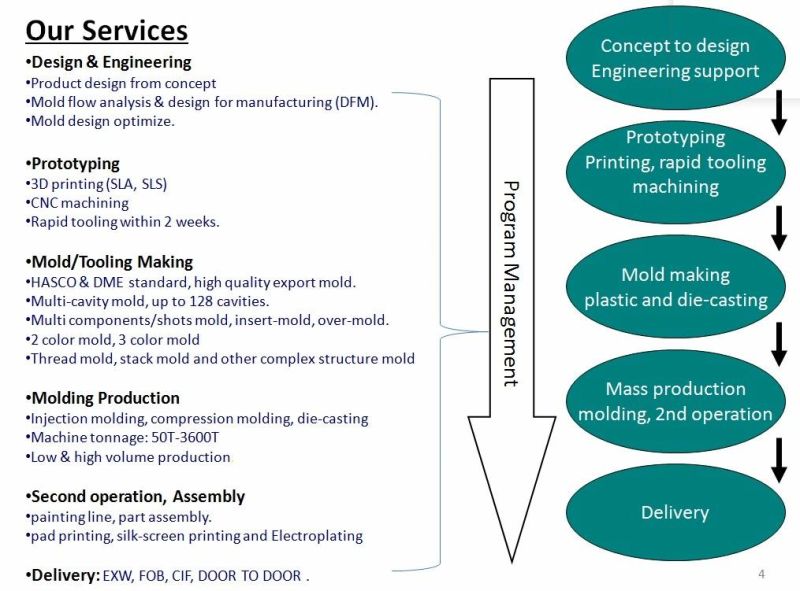

Dongguan Howe Precision Mold Co.,Ltd was established in Dongguan city. After more than 10 years of hard work, Howe has grown to be one of the highest reputable mould maker in China with 50 employees and 3000 sq. Meter working shop.

Up to now, Howe mold has exported about 2000 sets of moulds to 20 countries. The moulds we made include automotive parts (dashboards, inner decorating accessories, etc. ), electrical appliances (washing machine, air conditioner, refrigerator, television, etc. ), IT industry products (cell phones, computer, etc. ), householder products (microwave oven, juicer, etc. ), office accessories (telephone, printer, etc. ) as well as other varieties of products. We look forward to participating in the success of your next project.

Why Choose Us?

1. Manufacturing and exporting experience for more than10 years. ISO 9001 approved.

2. Products are supplied to over 50 countries.

3. One-stop service for plastic injection mould and plastic parts. Save time and save money for you.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. 24 hours (two shifts) / 6 days for production.

8. Professional design team, mold maker engineer. OEM/ODM service.

9. Professional QC and R&D teams to assure high quality.

10. Professional sales team.

11. No MOQ.

12. Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer's urgent demands.

13. Geographical advantages: within 30 minutes to airport or sea port, near to Hongkong.

Workshop

Our team

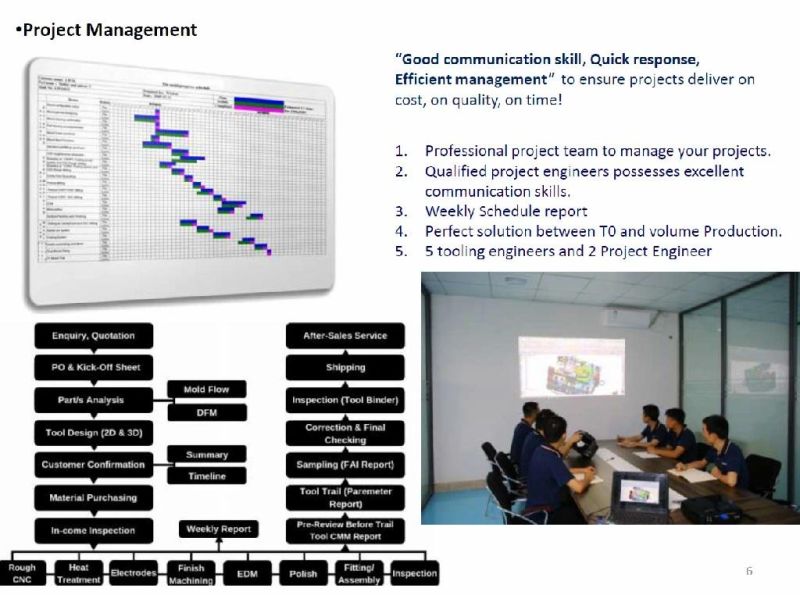

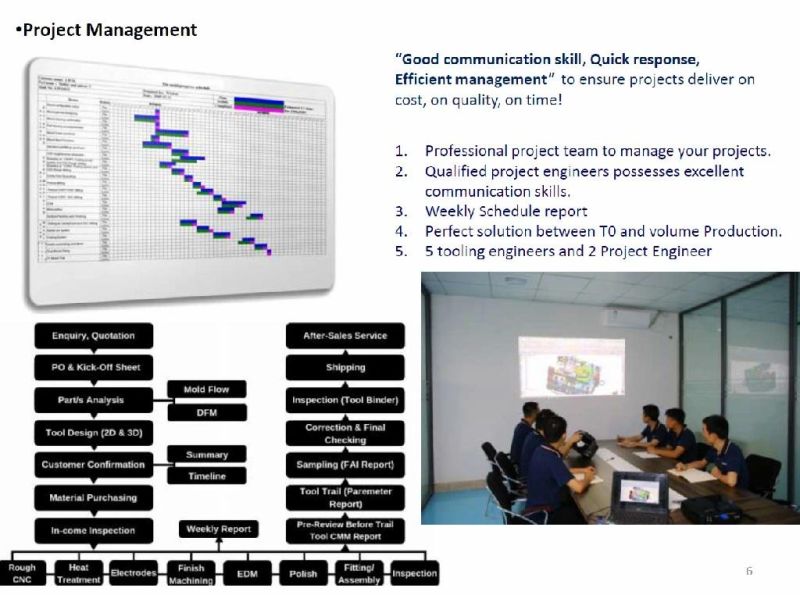

Process of mold making

| 1. Sample/Drawing | We need your detail requires clearly. |

| 2. Engineer Review | Material, cavity, Mould weight, give customer suggestion: |

| 3. Make quotation | Sales department and RD department make a meeting according to customer need |

| 4. Negotiation | Material, cavity, price, delivery time, payment term, etc. |

| 5. Place order | According to your own design or choosing our design. |

| 6. Mould design | We will communicate Exchange the opinion with you during making the drawing |

| 7. Tooling mould | After customers approve the mould design will start making mould. |

| 8. Mould process | Provide photos for customer show them tooling process |

| 9. Sample confirm | Send your sample to confirm it, if not satisfied by the customer. we modify mould. |

| 10. Delivery mould | Delivery mould after customer approve sample and arrange shipment. |

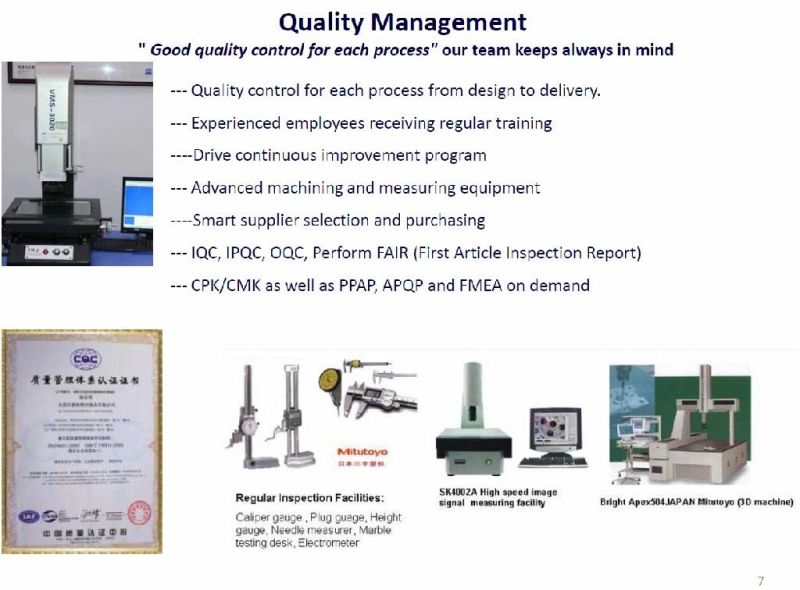

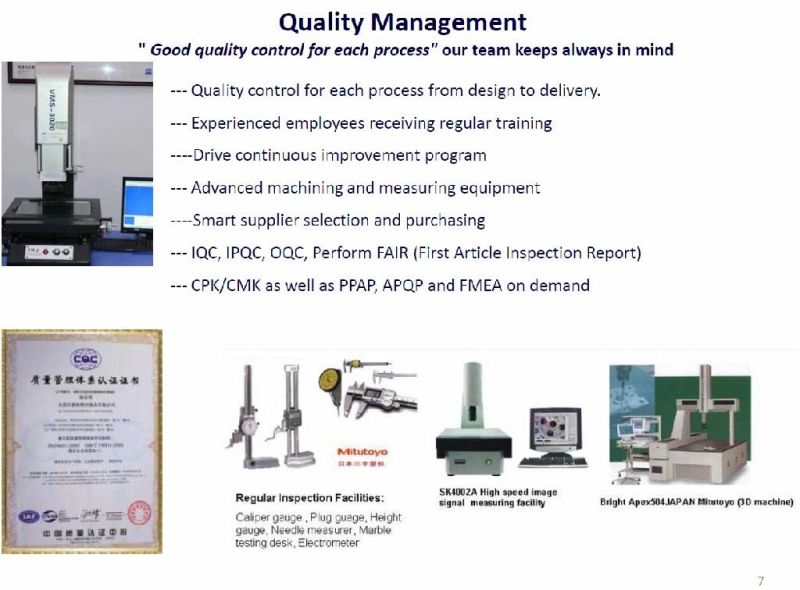

Quality assurance and service:

- Manufacturing and exporting experience for over 10 years. ISO 9001 approved &TS16949 approved .

- Products are supplied to over 50 countries.

- One-stop service for aluminum profiles, plastic parts, rubber parts, and moulds. Save time and save money for you.

- In-house mold design and building capabilities.

- No reclaimed material used to ensure high quality.

- Keep secret to your idea and your design.

- Professional design team, mold maker engineer. OEM/ODM service.

- Professional QC and R&D teams to assure high quality.

- Professional sales team. Good English capabilities and communication skills.

Dongguan Howe Precision Mold Co.,Ltd was established in Dongguan city. After more than 10 years of hard work, Howe has grown to be one of the highest reputable mould maker in China with 50 employees and 3000 sq. Meter working shop.

Up to now, Howe mold has exported about 2000 sets of moulds to 20 countries. The moulds we made include automotive parts (dashboards, inner decorating accessories, etc. ), electrical appliances (washing machine, air conditioner, refrigerator, television, etc. ), IT industry products (cell phones, computer, etc. ), householder products (microwave oven, juicer, etc. ), office accessories (telephone, printer, etc. ) as well as other varieties of products. We look forward to participating in the success of your next project.

Why Choose Us?

1. Manufacturing and exporting experience for more than10 years. ISO 9001 approved.

2. Products are supplied to over 50 countries.

3. One-stop service for plastic injection mould and plastic parts. Save time and save money for you.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. 24 hours (two shifts) / 6 days for production.

8. Professional design team, mold maker engineer. OEM/ODM service.

9. Professional QC and R&D teams to assure high quality.

10. Professional sales team.

11. No MOQ.

12. Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer's urgent demands.

13. Geographical advantages: within 30 minutes to airport or sea port, near to Hongkong.

Workshop

Our team