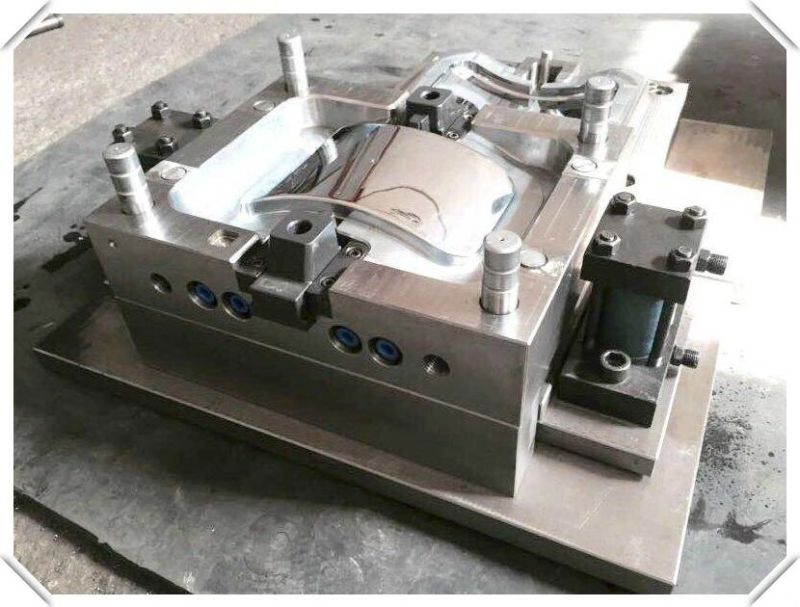

Injection Mold with Plastic Dustbin

Taizhou Lisi Plastic Houseware Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Home Use, Hardware

- Plastic Material:HDPE

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Runner:Hot Runner

Base Info

- Specification:customized

- Transport Package:Wooden Packing

- Matrial:P20

- Cavity:One

- Customized:Customized

- Installation:Mobile

- Design Software:Pro-E

- Model NO.:YX-1855

- Origin:China

- HS Code:8481719090

- Production Capacity:100set,One Year

Description

1.Quote

According Sample or 2D/3D drawing or Picture with detailed information , If the part some design is not good , we will give suggestion and solutions to customer

↓

2.Discussion

Mold material, cavity number, price, runner, payment, etc.

↓

3.Approved

Order confirmed

↓

4. Advance

Pay 50% by T/T

↓

5.Product Design Checking.

We will send 2D and 3D part drawing and PPT file for customer check

↓

5.Mould Design

According the Approved Part drawing , we will make the mold design and send to customer confirm

↓

6.Mold Steel Material and Component Prepare

After drawing confirmed , we will start to prepare the steel material and standard components

↓

7.Mold Processing

Send detailed reports with pictures to customer each week

↓

8.Mold Testing

Send Test samples with report to customer

↓

9. Mold Modification

According to customer's feedback

↓

10.Balance settlement

50% by T/T after the customer approved the test sample and mould quality.

↓

11.Packing and Delivery

Each Mold will be packing with some damageable spare parts , and send detailed pictures to customer

Q/C Inspect Moulds:

1.Mould Material Q/C

- Mould Steel Checking(Hardness, Crack ,Blow hole material defects )

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Machining Process Q/C

- Design checking (Part design, mould design,Including 2D drawing and 3D drawing)

- Each part of mould's size checking after machining according to 2D drawing

- Mold Test (check mould running conditions and T1 samples)

3.Make sure to follow and checking each points of customer's request before shipment